Grindmaster CC-302-20 User Manual

Page 10

Quarterly Cleaning

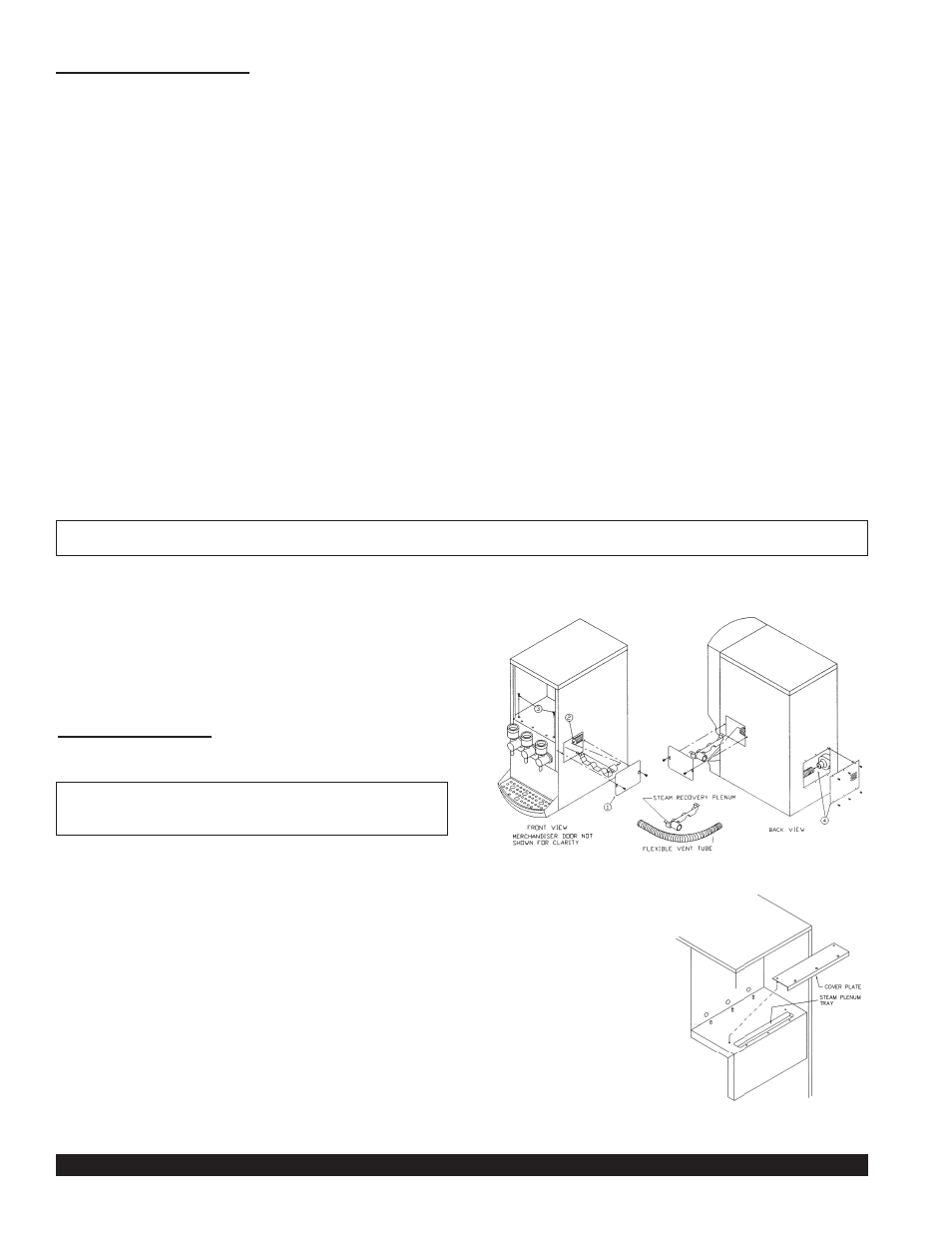

Cleaning the Steam Recovery Plenum Tray

WARNING: Risk of electric shock; Disconnect

from power before servicing!

1. Remove the side access panel (Refer to figure K)

2. Disconnect the flexible vent tube attached to the

recovery tray.

3. Remove the two screws which fasten the recovery

tray to the sheetmetal enclosure and remove the

recovery tray through the side access hole.

4. Remove the back access plate (refer to figure L). Disconnect and remove the

flexible vent tube from the blower housing. Carefully remove the flexible vent

tube from the machine's cabinet.

5. Wash, rinse, sanitize, and air dry the recovery tray and hose. Note: A long soft

bristle brush or small cloth towel may be used to clean the internal passage of

the flexible vent tube by pushing it through the tube. Rinse, sanitize and air

dry the tube.

6. Reassemble the parts in reverse order.

NOTE: PIC 5 and PIC 6 contain two ports on the plenum, three flexible tubes

and a barbed tee.

Figure K

Figure J

Figure L

Cleaning the Steam Plenum Tray (PIC 2/3/4/5/6 only) (Refer to Figure L)

CAUTION: Do not pour liquid into tray. Failure to comply will damage the dispenser and void the warranty.

1. Rotate dispense elbows on the hoppers to the “up” position and remove hoppers from machine.

2. Remove cover plate inside machine cabinet, located below hoppers.

3. Using a damp towel, wipe powder build up from

inside steam plenum tray.

4. Replace cover plate.

5. Replace hoppers and turn elbows down to the

dispense position.

Weekly Cleaning (cont.)

Page 10

Crathco® Powdered Beverage Dispensers

ƽ

Reassembling the Hoppers (PIC 4)

IMPORTANT: All components must be completely dry prior to reassembly.

1. Place the bearings inside the hopper in proper position.

2. Secure the bearings by attaching the nuts to the bearings at the outside rear hopper opening. Tighten using

only your fingers.

3. Insert auger into the lower front hopper opening, making sure the threaded end of the auger spring drive

shaft completely inserts into the rear bearing in the rear of the hopper. The auger threads should be

accessible from the outside rear of the hopper.

4. Secure the coupling onto the auger by turning counterclockwise. Secure the auger with one hand while

attaching the coupling with the other.

5. Replace the auger pinwheel making sure the pins are securely positioned inside the locator holes in the

hopper (this hopper only). * See below for wide hopper. For either hopper, turn coupling and make sure

pinwheel in properly installed and turns freely.

6. Replace the dispense elbow in the “UP” position.

7. Fill the hopper with product and replace the cover.

8. Reinstall the hopper into the machine; making sure it is properly aligned.

9. Turn the elbow down toward the mixing funnel, keeping it lined up over the funnel opening.

* For wide hopper: Replace pinwheel assembly by inserting gear through the pinwheel and inserting threads

through the hopper wall. Insert flat washer on outside and finger-tighten wing nut securely.

ƽ