Evaporative cooling modules, Evap module start-up – Greenheck Fan HRE-20 User Manual

Page 7

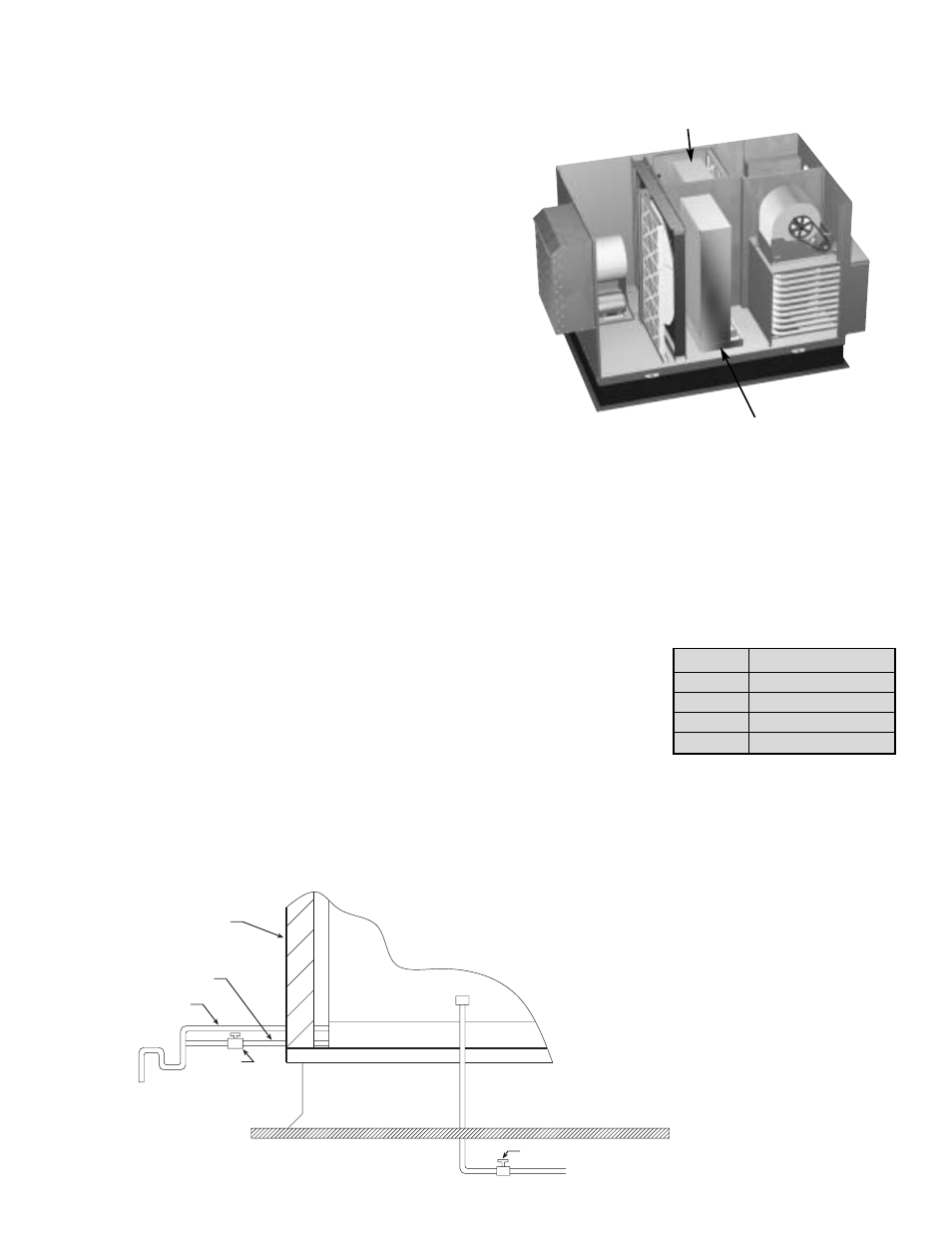

1. After the energy recovery unit is set in place, run

the overflow and drain lines to the exterior fittings

on the evaporative cooler (drain & overflow

connections at unit are

3

⁄

4

-inch female pipe thread).

The supply line can be attached at the

downstream side of the evaporative cooler. A

manual shut off valve should be mounted in the

supply line near the unit for servicing purposes.

Also, a trap should be installed in the drain line to

prevent sewer gas from being drawn into the unit

(see Figure 8).

2. The cooler will be prewired by the factory.

3. Check to make sure that the pump filter is around

the pump inlet.

4. Turn the water on and allow the pan to fill up with

water. The float should be adjusted to provide 2

inches of water depth in the sump.

5. Saturate the media without any airflow through the

unit. A jumper wire is required on the terminal strip

to provide power to the evaporative cooler pump

(see the wiring diagram for the proper location).

This saturation process will break-in the media and

minimize the odors associated with the media. The

media’s break-in period should be no less than 20

minutes. When the process is complete, remove

the jumper wires in the control center.

Note:

Evaporative media may foam for a short

period following the initial start-up. Leave

the bleed-off valve fully open until the

foaming stops.

6. After the media break-in period, the water flow

rate over the media needs to be checked. The

pumps should provide enough water to saturate

the media in 1-3 minutes. If adequate flow rate is

not achieved, consult with the factory.

7. The water bleed-off rate will now need to be

adjusted. This measurement is 3 to 6 percent of

the media flow rate. The recommended flow rate is

1

1

⁄

2

to 2 GPM per

square foot of

media pad top area

(see table at right).

After the unit has

been installed and

running for two

weeks the unit should be checked for mineral

deposits. If there are deposits, the bleed-off rate

needs to be increased. Some areas of the country

have water with greater amounts of dissolved

minerals requiring a higher bleed-off rate.

8. Verify that both airflow and system static pressure

are in agreement with the specifications. If these

conditions are met, check for water carry over

from the discharge side of the media. If carry over

is observed, check the distribution header for

holes or tears and the

water standoff tube for

blockage.

9. After all final

adjustments are made,

remove the jumper

wires and replace all

access panels. The

unit is now ready for

operation.

It is important to mount the heat recovery unit level to

ensure proper operation and water drainage. Piping

should be of adequate size to provide sufficient

supply of water to meet the maximum demand of the

evaporative coolers.

Evap Module Start-Up

Evaporative Cooling Modules

7

Roof Curb

Roof Line

Drain

Line

Trap

Overflow

Drain Line

Manual

Shutoff

Valve

Evaporative

Cooling

Media

Manual Shutoff Valve

Supply Line

Sump

Side of HRE Unit

Indirect Evaporative Cooler

(Exhaust/Scavenger Airstream)

Direct Evaporative Cooler

(Outdoor/Supply Airstream)

FIGURE 8

Unit Size

Media Pad Top Area

HRE-20

1.5 ft

2

HRE-45

2 ft

2

HRE-55

2.5 ft

2

HRE-90

3.3 ft

2