Troubleshooting guide – Graco BULLDOG 222248 User Manual

Page 7

7

306–646

TROUBLESHOOTING GUIDE

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including fluid injec-

tion, splashing in the eyes or on the skin, or injury from moving

parts, always follow this procedure whenever you shut off the

pump, when checking or servicing any part of the spray/dis-

pensing system, when installing, cleaning or changing spray

tips/nozzles, and whenever you stop spraying/dispensing.

1. Engage the gun/valve safety latch.

2. Shut off the air to the pump.

3. Close the bleed–type master air valve (required in your

system).

4. Disengage the safety latch.

5. Hold a metal part of the gun/valve firmly to the side of a

grounded metal pail, and trigger the gun/valve to relieve

pressure.

6. Engage the gun/valve safety latch.

7. Open the drain valve and/or the pump bleeder valve (re-

quired in your system), having a container ready to catch

the drainage.

8. Leave the drain valve open until you are ready to use the

system again.

If you suspect that the spray tip/nozzle or hose is completely

clogged, or that pressure has not been fully relieved after fol-

lowing the steps above, VERY SLOWLY loosen the tip guard

retaining nut, nozzle, or hose end coupling and relieve pres-

sure gradually, then loosen completely. Now clear the tip/noz-

zle or hose.

WARNING

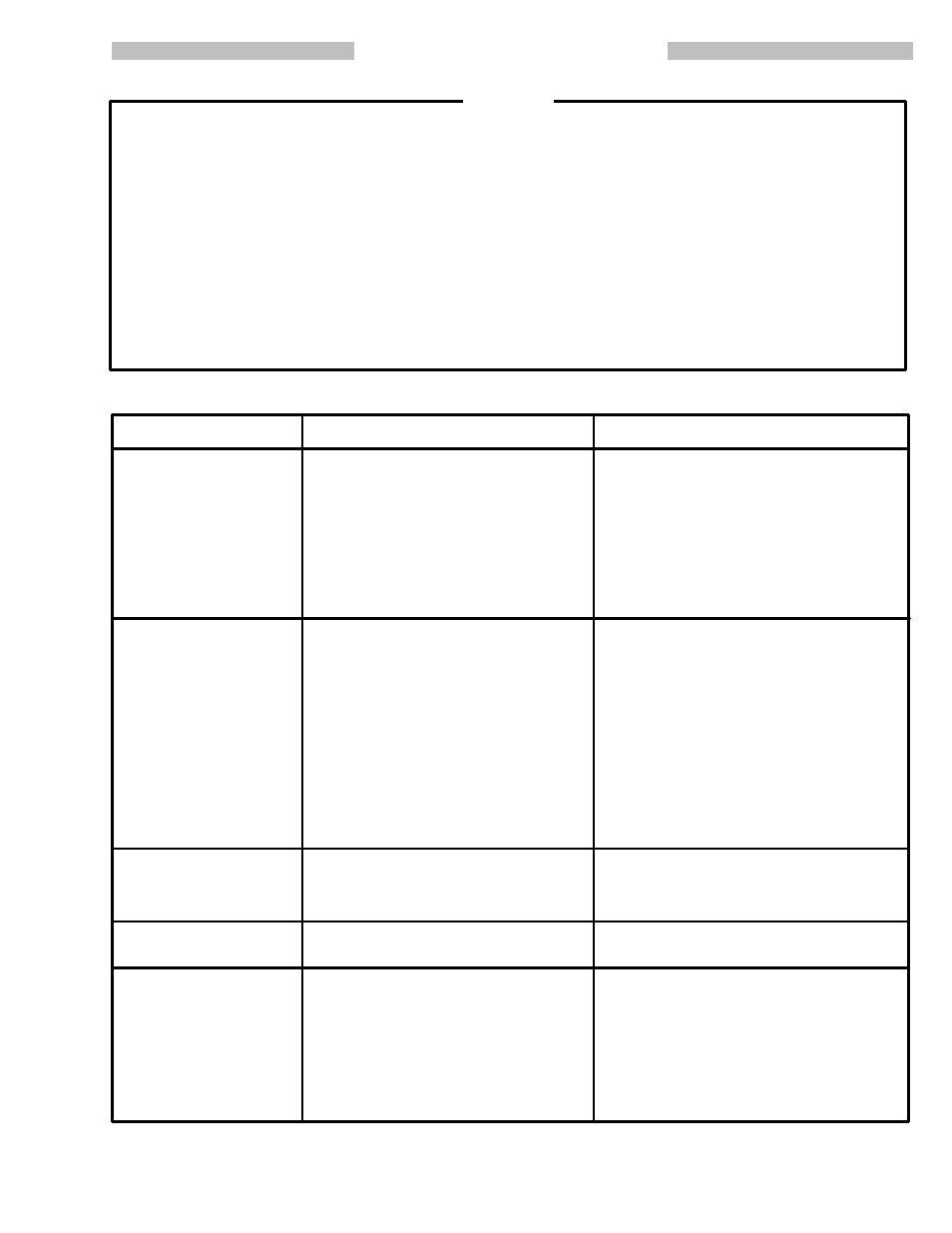

NOTE: Check everything in the troubleshooting guide below before disassembling the pump.

Exhausted fluid supply

Restricted line or inadequate air supply

Insufficient air pressure, closed or clogged air

valves, etc.

Obstructed fluid hose or gun/valve

Fluid dried on the displacement rod

Dirty or worn air motor parts

Exhausted fluid supply

Restricted line or inadequate air supply

Insufficient air pressure, closed or clogged air

valves, etc.

Obstructed fluid hose or gun/valve

Bleeder valve open or worn

Air leaking into supply drum

Fluid too heavy for pump priming

Worn throat packings in displacement pump

Fluid too heavy for pump priming

Held open or worn intake valve or packings

Held open or worn piston valve or packings

Exhausted fluid supply

Fluid too heavy for pump priming

Held open or worn piston valve or packings

Held open or worn intake valve or packings

Worn throat packings in displacement pump

CAUSE

Refill and reprime or flush.

Clear; see

TECHNICAL DATA on back cover.

Open, clear.

Clear.*

Clean. See

SERVICE.

Clean, service. See air motor manual, supplied.

Refill and reprime or flush.

Clear. See

TECHNICAL DATA on back cover.

Open, clear.

Clear.*

Close; replace.

Check inductor or ram plate seal.

Use pump bleeder valve (see page 5). Use inductor or

ram unit.

Replace gland/packing stack.

Use pump bleeder valve (see page 5). Use inductor or

ram unit.

Clear valve; replace gland/packing stack.

Clear valve; replace gland/packing stack.

Refill and reprime or flush.

Use pump bleeder valve (see page 5). Use inductor or

ram unit.

Clear valve; replace packings.

Clear valve; replace gland/packing stack.

Replace gland/packing stack.

PROBLEM

SOLUTION

Pump fails to operate

Pump operates but output

low on both strokes

Erratic or accelerated

pump speed

*

To clear the pump, follow the

Pressure Relief Procedure Warning, above. Disconnect the fluid line. If the pump starts when the

air is turn on, then the fluid hose or gun/valve is obstructed.

Pump operates but output

low on downstroke

Pump operates but output

low on upstroke