Design suggestions – Grizzly G1029 User Manual

Page 20

-18-

G1028Z/G1029 Dust Collector

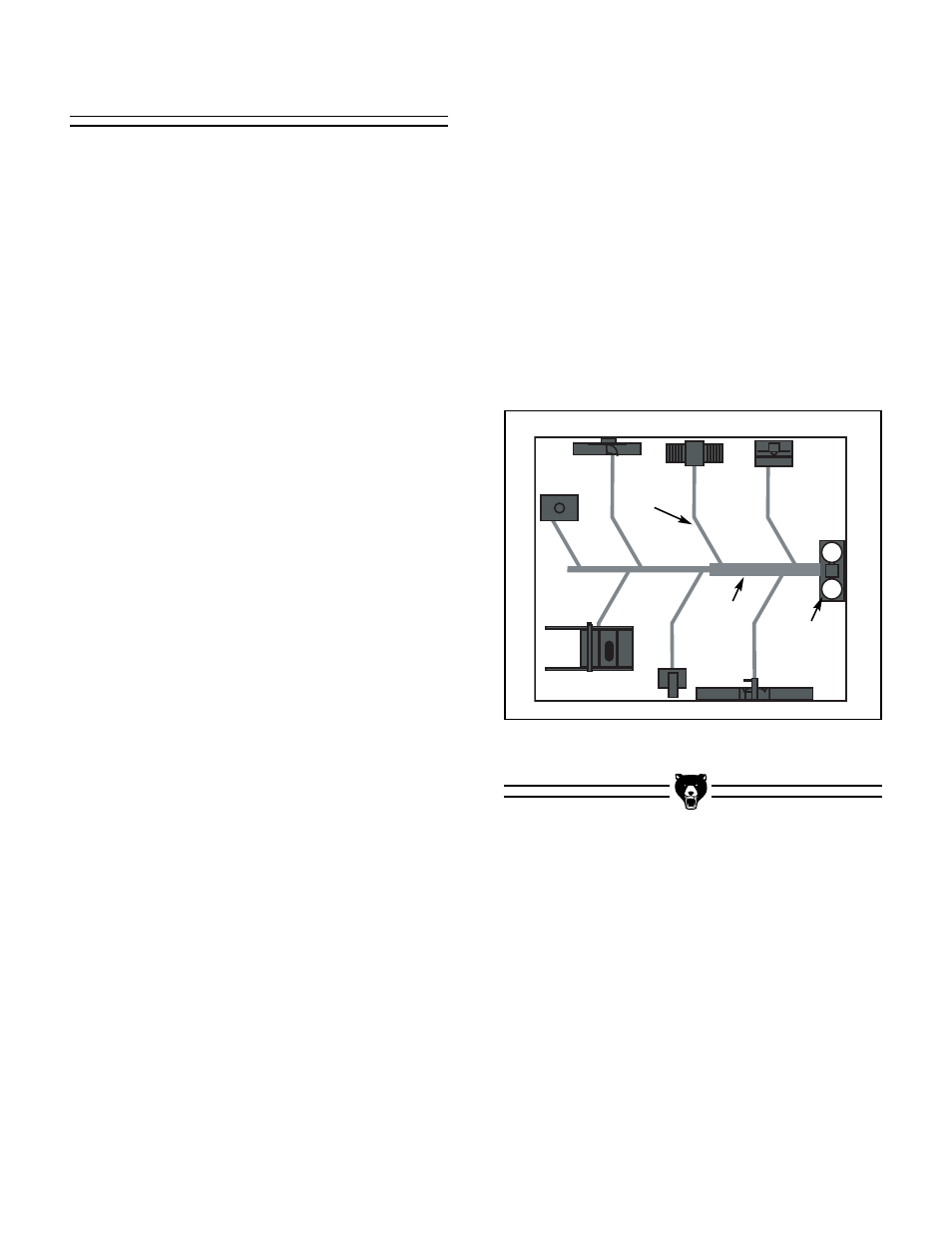

The best way to plan your new system is to draw

a bird’s eye view (as shown in

Figure 14

) of your

shop and sketch the following:

1.

Your desired location of the dust collector,

usually in a corner or along a wall.

2.

The location of each machine in the system.

3.

The location of the main line duct and each

branch line.

4.

The location of any obtrusion such as a joist

or heating duct, that will require special duct

routing.

Figure 14.

Bird’s eye planning view.

6''

5''

4''

4''

4''

4''

4''

4''

4''

Main Line

Branch Line

When designing a successful dust collection sys-

tem, planning is the most important step. Before

you set out to run the first section of duct, consid-

er these general guidelines for an efficient sys-

tem:

1.

Machines that produce the most saw dust

should be placed nearest to the dust collec-

tor. These machines include thickness plan-

ers, shapers, sanders and bandsaws.

2.

Ideally, you should design the duct system to

have the shortest possible mainline run and

to have short secondary branch ducts.

3.

Directional changes should be kept to a min-

imum. The more directional change fittings

you use, the greater the loss of overall pres-

sure.

4.

Gradual directional changes are more effi-

cient than sudden directional changes (i.e.

use the largest corner radius possible when

changing hose or pipe direction).

5.

Each individual machine should have a blast

gate to control suction from one machine to

another.

6.

The simpler the system, the more efficient

and less costly it will be.

Design Suggestions

Dust

Collector