Basic bending operations, Clamp adjustment – Grizzly Bending Brake T21319 User Manual

Page 2

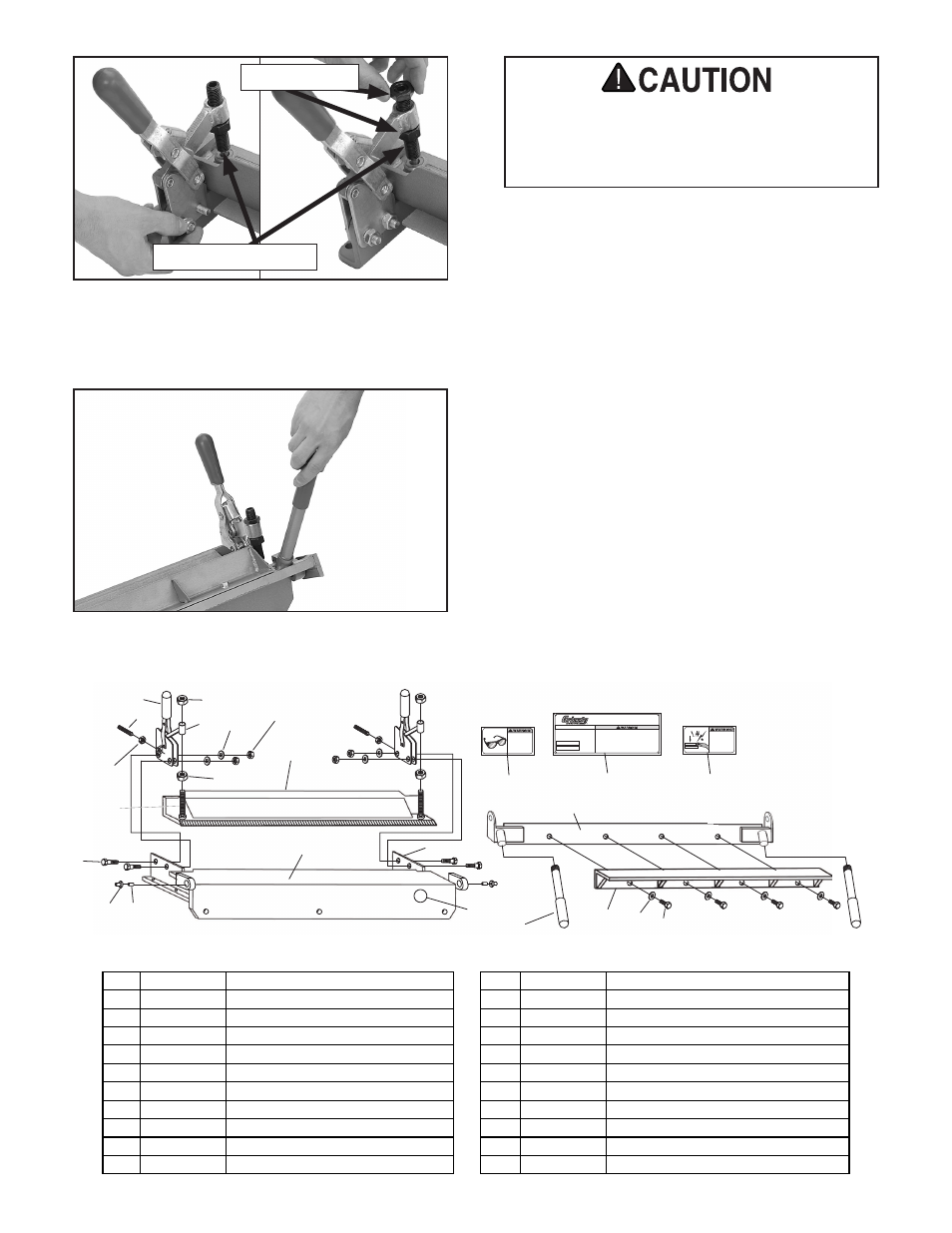

4. screw the two breaker bar levers into the

breaker bar holes, as shown in

Figure 5.

basic bending operations

1. open the bending brake and place the work-

piece beneath the clamping angle.

2. Close the clamp assemblies until they lock.

if the workpiece is to thick or too thin for

the clamps, adjust the clamps according to

clamp adjustment on this page.

3. When the workpiece is secured in the bend-

ing brake, lift the breaker bar levers to form

the desired angle.

clamp adjustment

1. Without turning the clamping set screw, turn

the adjusting nuts clockwise to adjust for

thicker workpieces and counterclockwise to

adjust for thinner workpieces. Adjust each

clamp an equal amount.

Figure 5. Breaker bar lever installation.

t21319 breakdown and parts list

PINCH

HAZARD!

Keep hands away

from clamp area

when clamping or

bending.

EYE INJURY

HAZARD!

Always wear safety

glasses when using

this machine.

MODEL H2788

24" BENDING BRAKE

Specifications

Max. Workpiece Thickness: 18 Ga.

Max. Bend: 145°

Max. Workpiece Width: 27-1/2"

Weight: 60 lbs.

To reduce the risk of serious personal injury when using this

machine:

1. Read and understand the manual before starting.

2. Always wear eye protection.

3. Wear heavy leather gloves when handling sheet metal.

4. Do not exceed the rated capacity of this machine.

5. Do not use a breaker bar to gain leverage.

6. Always firmly clamp workpiece before bending.

1

3

7

5

2

6

5

10

11

3

8

4

14 13

15

16

21

22

23

24

17

18 20 19

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

1

PT21319001 CLAMP

14

PT21319014 FLANGE BEARING

2

PSS39M

SET SCREW M10-1.5 X 50

15

PT21319015 BASE

3

PN05M

HEX NUT M16-1.5

16

PT21319016 BREAKER BAR

4

PB01M

HEX BOLT M10-1.5 X 30

17

PT21319017 THREADED LEVER M20-1.75

5

PN02M

HEX NUT M10-1.5

18

PT21319018 BREAKER ANGLE

6

PLW06M

LOCK WASHER 10MM

19

PB03M

HEX BOLT M8-1.25 X 16

7

PT21319007 COLLAR

20

PW01M

FLAT WASHER 8MM

8

PT21319008 SPECIAL SET SCREW M10-1.5 X 90

21

PT21319021 PINCH HAZARD WARNING

10

PT21319010 CLAMPING ANGLE

22

PT21319022 MACHINE ID LABEL

11

PT21319011 CLAMP MOUNTING PLATE

23

PLABEL-11D SAFETY GLASSES LABEL

13

PT21319013 PIVOT PIN 16 X 50

24

PPAINT-1

GREEN TOUCH-UP PAINT

Figure 4. Clamp installation.

Adjusting nuts

Clamping set screw

the bending brake must be clamped or

secured to a workbench before being used.

Failure to do so can lead to personal injury

or machine damage!