Goodman Mfg Seer "m" series PG 15 User Manual

Page 13

13

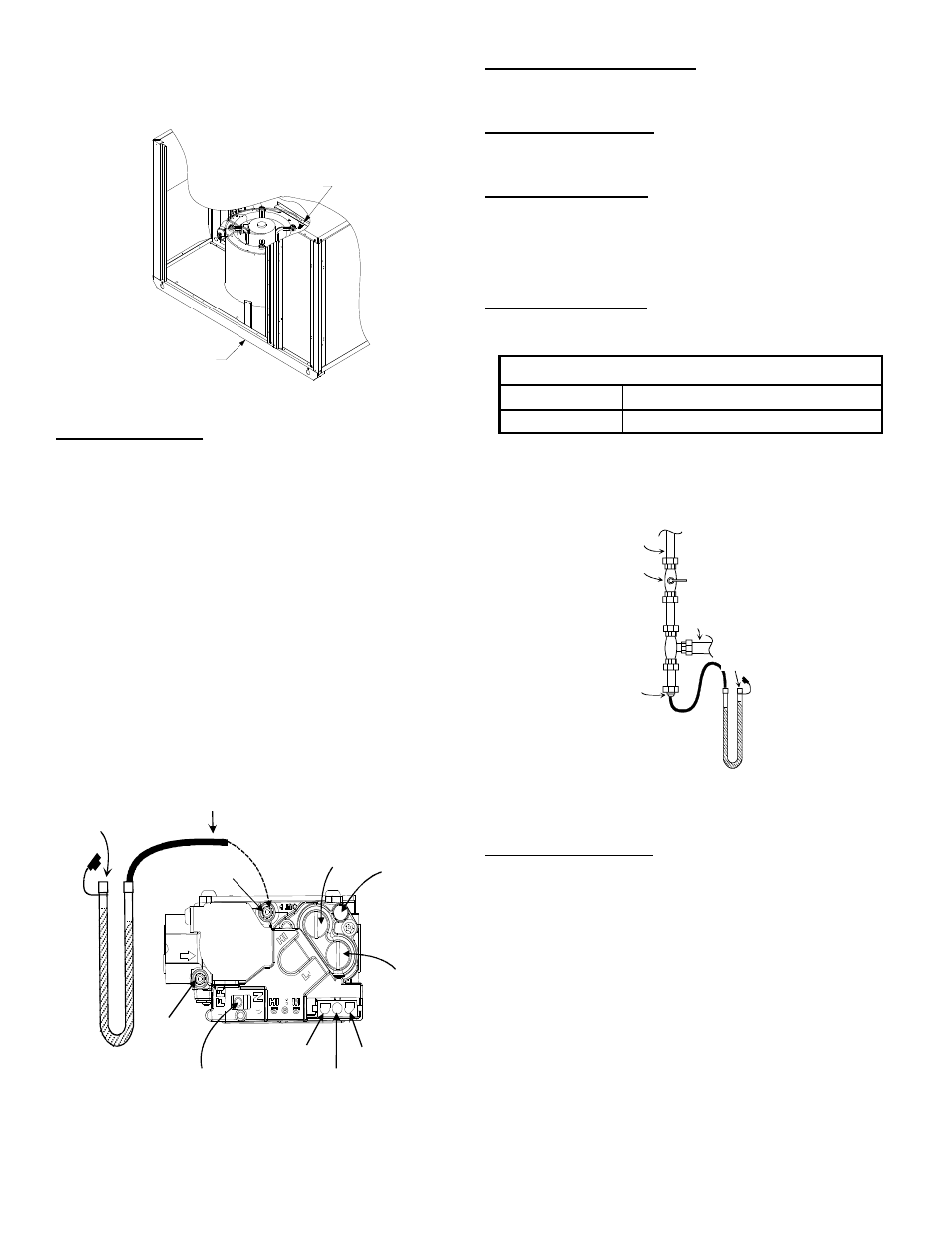

If the power to the unit is interrupted during the heating cycle, it

may cause the secondary limit to trip. Once the blower

compartment temperature drops below the limit reset

temperature, the limit will automatically reset.

Secondary

Control Limit

Back of Unit

Secondary Limit Control

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn off the electrical power supply to the unit.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the unit by

removing screws.

5. This unit is equipped with an ignition device which

automatically lights the main burner. DO NOT try to light

burner by any other method.

6. Move the gas control valve switch to the OFF position. Do

not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is important

because some types of gas are heavier than air. If you

have waited five minutes and you do smell gas,

immediately follow the warnings on page 4 of this manual.

If having waited for five minutes and no gas smell is noted,

move the gas control valve switch to the ON position.

9. Replace the heat exchanger door on the side of the unit.

10. Open the manual gas valve external to the unit.

11. Turn on the electrical power supply to the unit.

12. Set the thermostat to desired setting.

On/Off Switch

Inlet

Pressure Boss

High Fire

Coil Terminal (HI)

Low Fire

Regulator Adjust

Manometer

Manometer

Hose

A

High Fire Regulator

Adjust

Regulator

Vent

Common

Terminal (C)

Coaxial Coil

Terminal (M)

Outlet

Pressure Boss

Open to

Atmosphere

White-Rodgers Model 36G54 connected to Manometer

Gas Supply And Manifold Check

Gas supply pressure and manifold pressure with the burners

operating must be as specified on the rating plate.

Gas Inlet Pressure Check

Gas inlet pressure must be checked and adjusted in

accordance to the type of fuel being consumed.

With Power And Gas Off:

1. Connect a water manometer or adequate gauge to the

inlet pressure tap of the gas valve.

Inlet gas pressure can also be measured by removing the

cap from the dripleg and installing a predrilled cap with a

hose fitting.

With Power And Gas On:

2. Put unit into heating cycle and turn on all other gas

consuming appliances.

Natural

Min. 5.0" W.C., Max. 10.0" W.C.

Propane

Min. 11.0" W.C., Max. 13.0" W.C.

INLET GAS PRESSURE

NOTE: Inlet Gas Pressure Must Not Exceed the Maximum

Value Shown.

If operating pressures differ from above, make necessary

pressure regulator adjustments, check piping size, etc., and/

or consult with local utility.

Gas Line

Gas

Shutoff

Valve

Gas Line

To Furnace

Drip Leg Cap

With Fitting

Manometer Hose

Manometer

Open To

Atmosphere

Measuring Inlet Gas Pressure

Alternate Method

Manifold Pressure Check

1 Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2. Turn off all electrical power to the system.

3. Back outlet pressure test screw (inlet/outlet pressure boss)

out one turn (counterclockwise, not more than one turn).

4. Attach a hose and manometer to the outlet pressure boss

of the valve.

5. Turn ON the gas supply.

6. Turn on power and energize main (M) solenoid. Do not

energize the HI solenoid.

7. Measure gas manifold pressure with burners firing. Adjust

manifold pressure using the Manifold Gas Pressure table

shown below.