2 exhaust manifold procedure, 3 intake manifold procedure, 4 cylinder head procedure – Generac 005031-2 User Manual

Page 20: 5 cooling system

18

FIRST 100 OPERATING HOURS

1. Change engine oil and oil filter. After initial

change, service engine oil and filter at 150 operat-

ing hours or six months, whichever comes first.

2. Retorque cylinder head (see torque specs).

3. Retorque intake and exhaust manifold (see torque

specs).

EVERY 500 OPERATING HOURS

1. Service

air

cleaner.

2. Check

starter.

3. Check engine DC alternator.

EVERY 800 OPERATING HOURS

1. Retorque cylinder head (see torque specs).

2. Retorque intake and exhaust manifold (see torque

specs).

3. Check

engine

compression.

4. Check

valve

clearance.

4.2

EXHAUST MANIFOLD PROCEDURE

1. If necessary, clean gasket surfaces on exhaust

manifold and cylinder head.

2. Install exhaust manifold and exhaust manifold

gasket.

3. Install

fasteners.

NOTE:

Exhaust manifold fasteners must be tightened in

two stages.

4. Tighten fasteners to 20-30 N-m (15-22 lb-ft) dur-

ing the first stage.

5. Retighten fasteners to 60-80 N-m (44-59 lb-ft)

during the second stage.

4.3 INTAKE

MANIFOLD

PROCEDURE

1. Clean and inspect the mounting surfaces of the

intake manifold and the cylinder head. Both sur-

faces must be clean and flat (Figure 4.1).

2. Clean and lightly oil the manifold bolt/stud

threads.

Figure 4.1 — Intake Manifold Installation

3. Install a new lower intake manifold gasket.

4. Position the lower intake manifold to the cylinder

head.

5. Install retaining bolts/studs finger tight.

6. Tighten all bolts/studs to specifications in the

tightening sequence shown:

• First pass = 7=10 N-m (5-7 lb-ft).

• Final pass = 26-38 N-m (19-28 lb-ft).

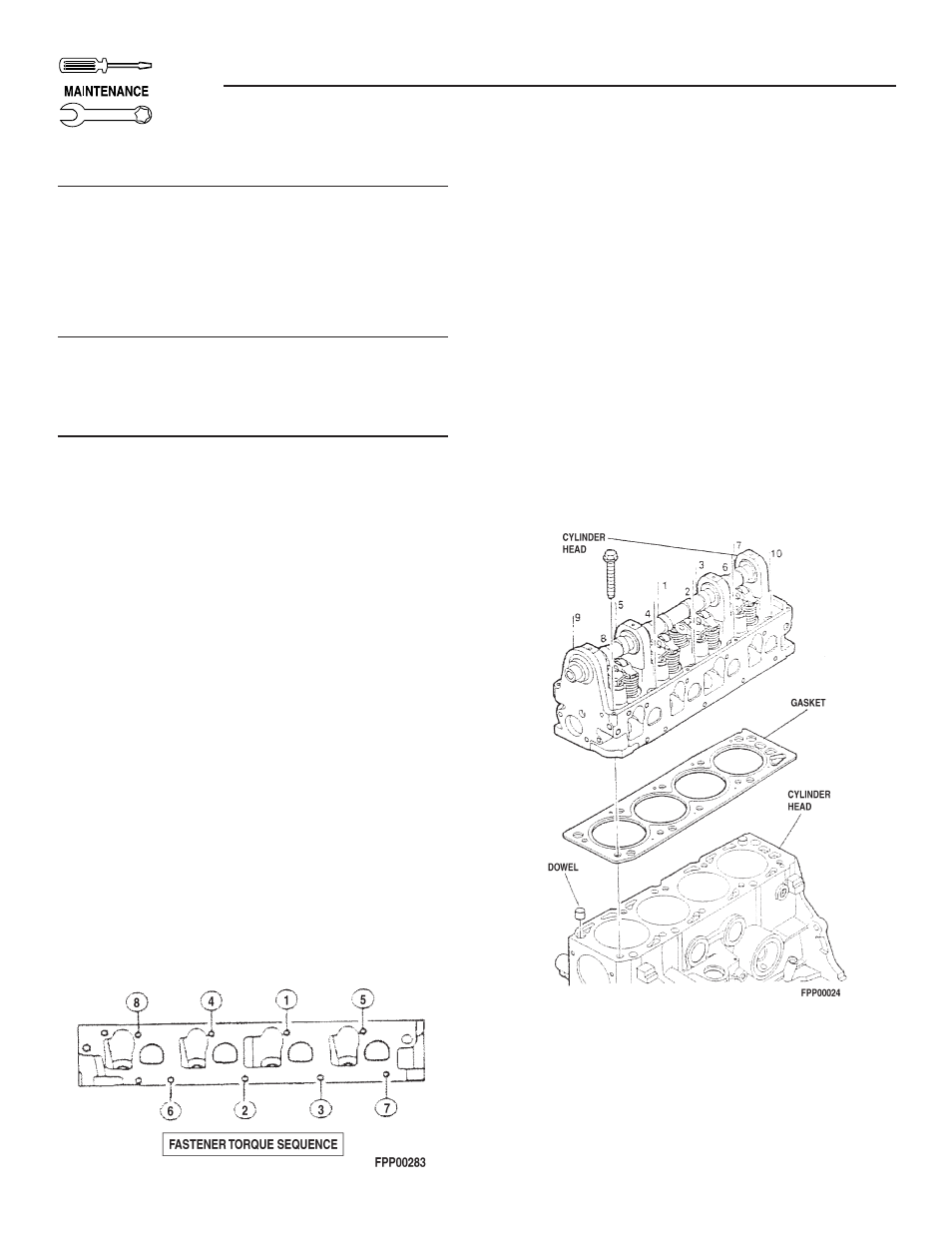

4.4 CYLINDER HEAD PROCEDURE

1. Position head gasket on the block (Figure 4.2).

2. Position cylinder head to cylinder block.

3. Install 10 cylinder head bolts in numerical

sequence. Tighten to 70 N-m (52 lb-ft) in sequence.

Retighten to 70 N-m (52 lb-ft) in sequence. Then

turn all head bolts an additional 90 - 100 degrees

in sequence.

Figure 4.2 — Cylinder Head Installation

4.5 COOLING

SYSTEM

Air intake and outlet openings in the generator com-

partment must be open and unobstructed for contin-

ued proper operation. This includes such obstruc-

tions as high grass, weeds, brush, leaves and snow.

Without sufficient cooling and ventilating air flow, the

engine/generator quickly overheats, which causes it

to shut down. (See the installation diagram.)

Section 4 — Maintenance

Liquid-cooled 25 kW Generators