9 voltage regulator adjustment – Generac 005031-2 User Manual

Page 19

17

Switch Position 8 — Selects whether the control is

in the Normal Mode of operation or Test Mode. In the

Normal Mode of operation, pre-determined governor

gains are used and the gain trimpots on the control

board (Gain, Stability, and Differential) are not active

and have no effect on the gains. In Test Mode the gain

trimpots are active and can be adjusted. See Section

3.4.

3.9

VOLTAGE REGULATOR

ADJUSTMENT

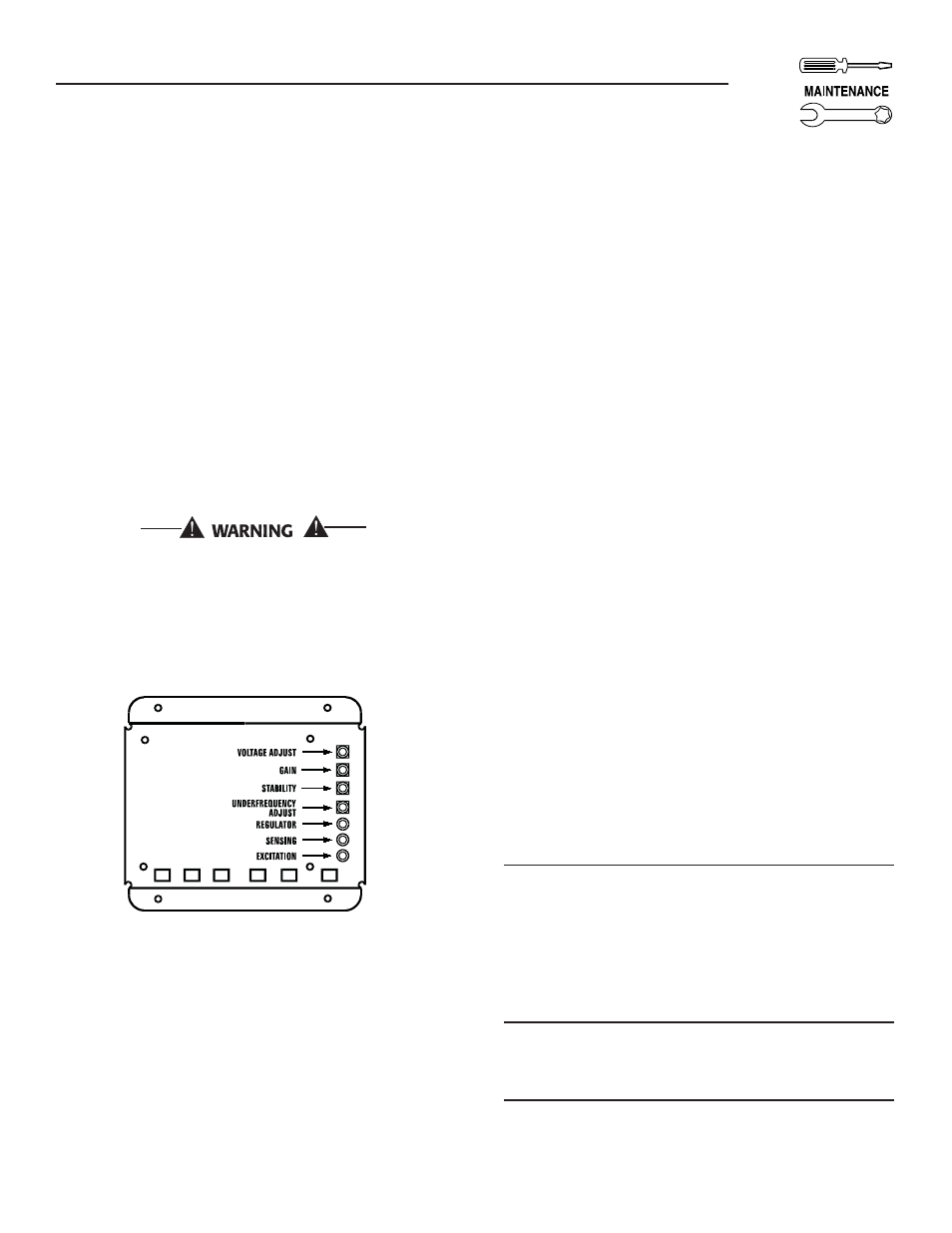

Four adjustment potentiometers are provided on

the voltage regulator installed in the control panel

(Figure 3.4). These are (a) voltage adjust, (b) gain, (c)

stability and (d) underfrequency adjust. The voltage

regulator potentiometers have been factory set and

SHOULD NOT be adjusted. If however, adjustments

are necessary, contact the local Dealer to implement

the following procedure.

High voltage is present inside the control panel

during this procedure.

1. Disconnect all electrical loads from the generator

(initial adjustments are done under no-load con-

ditions).

Figure 3.4 — Voltage Regulator

2. Connect an accurate AC voltmeter and AC fre-

quency meter to the generator’s AC output leads.

3. On the voltage regulator, set the potentiometers

as follows:

A. Turn the Voltage Adjust pot fully counterclock-

wise (CCW).

B. Set the GAIN pot to its centered (mid) position.

C. Set the STABILITY pot to its centered (mid)

position.

D. DO NOT adjust the UNDERFREQUENCY

ADJUST pot.

4. Start the engine. Let it stabilize and warm up at

no-load.

5. Verify that the three voltage regulator’s LED’s are

ON.

6. Check the reading on the AC frequency meter.

7. Turn the voltage regulator’s VOLTAGE ADJUST

pot to obtain a line-to-line voltage of:

A. 240 VAC if the generator has been configured for

60 Hertz operation.

B. 200 VAC if the generator has been configured for

50 Hertz operation.

8. If the RED REGULATOR LED is flashing, adjust

the STABILITY pot in either direction until the

flashing stops.

9. Apply an electrical load and check the engine

speed recovery.

A. Adjust the UNDERFREQUENCY ADJUST pot

CCW to reduce load during engine recovery.

B. For flat regulation (no voltage decrease as fre-

quency drops) set the UNDERFREQUENCY

ADJUST pot fully CW.

C. To obtain a constant voltage regulation as fre-

quency decreases, set the UNDERFREQUENCY

ADJUST pot fully CCW.

10. With the electrical load still applied, check the

REGULATOR LED for flashing. If the LED is

flashing, adjust the STABILITY pot until the flash-

ing stops.

11. If better response is needed, adjust the GAIN pot

clockwise (CW) as needed. Then (if needed) cor-

rect for stability by adjusting the STABILITY pot.

12. Turn OFF the electrical loads.

13. Verify that all the voltage regulator’s LED’s are

ON.

14. Turn OFF the generator.

4.1

MAINTENANCE PERFORMED BY

AUTHORIZED SERVICE FACILITIES

EVERY THREE MONTHS

1. Check

battery

condition.

2. Inspect and test fuel system.

3. Check

transfer

switch.

4. Inspect

exhaust

system.

5. Check engine ignition system.

6. Check

fan

belts.

ONCE EVERY SIX MONTHS

1. Test Engine Safety Devices (low oil pressure, low

coolant level, high coolant temperature).

ONCE ANNUALLY

1. Test engine governor; adjust or repair, if needed.

2. Clean,

inspect

generator.

3. Flush

cooling

system.

Section 4 — Maintenance

Liquid-cooled 25 kW Generators