Pre-start-up checks – Greenheck Fan Laboratory Exhaust System Vektor-HS User Manual

Page 8

Vektor-H Applications with Variable

Frequency Drive (VFD)

For Vektor systems with single-point, three-phase

wiring per blower, the isolation damper actuator will be

powered via a step-down transformer, which is wired to

the fan disconnect, as shown in the wiring diagrams on

page 7.

If fan flow (motor speed) is to be controlled using a

variable frequency drive with this wiring, the reduced

voltage and frequency supplied to the fan will cause

control problems with the isolation damper actuator.

When a project’s Vektor control sequence requires

the use of a VFD, it is suggested that the control

contractor supply the isolation damper actuator voltage,

independent of the power supplied to the Vektor fan

motor.

NOTE

Any increase in fan speed represents a substantial

increase in horsepower required from the motor.

Always check motor load amperage and compare to

nameplate rating when changing fan speed.

Unit

Size

Inlet Cone to Backplate

A Dimension

± Tolerance (in.)

A Dimension

± Tolerance (mm)

9

3 3/16

± 1/8

81

± 3

10

3 7/16

± 1/8

87

± 3

12

4

± 1/8

102

± 3

13

4 7/16

± 1/8

113

± 3

16

5 7/16

± 1/8

138

± 3

18

6 3/8

± 1/8

162

± 3

22

7 13/16

± 3/16

198

± 5

24

8 5/8

± 1/4

219

± 6

30

10 9/16

± 3/8

268

± 10

36

12 3/4

± 3/8

324

± 10

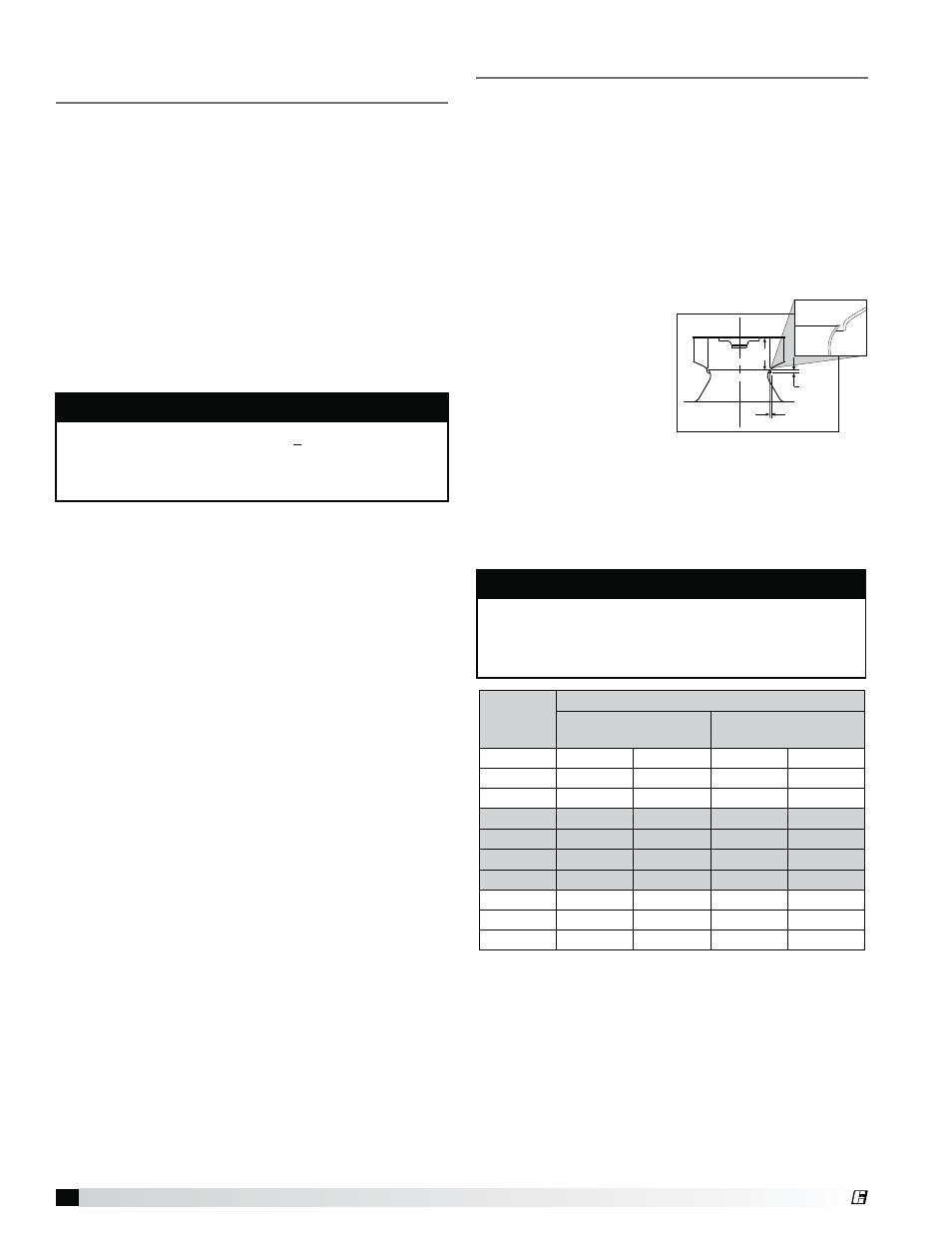

Radial Gap is adjusted by loosening the inlet cone

bolts and centering the cone on the wheel. If additional

adjustment is required to maintain a constant radial gap,

loosening the bearing bolts and centering the wheel is

acceptable as a secondary option.

Overlap or offset, is adjusted by loosening the wheel

hub from the shaft and moving the wheel to the desired

position along the shaft. The transition between the inlet

cone and wheel should be as shown; there is a smooth

feel to the profile when moving from one component to

the other.

Pre-Start-Up Checks

Check all fasteners for tightness.

Check radial gap, overlap and wheel alignment. The

wheel should be aligned as shown. Although the wheel

position is preset and the unit is test run at the factory,

movement may occur during shipment.

The radial gap should be consistent at all locations

between the centrifugal wheel and the inlet cone.

Centering may be accomplished by loosening the inlet

cone bolts and repositioning the inlet cone.

To obtain the optimum performance, the centrifugal

wheel must overlap the inlet

cone. Adjustments can be

made by loosening the set

screws in the wheel and

moving the wheel to the

desired position.

Wheel rotation should

be in the same direction

as the rotation decal affixed to the unit. (Clockwise

rotation is correct as viewed from fan inlet). For 3-phase

installations, fan rotation can be reversed by simply

interchanging any two of the three electrical leads. For

single phase installations, follow the wiring diagram

located on the motor.

Radial Gap

Overlap

A

Inlet

Cone

Wheel

NOTE

For Vektor-HS fans provided from the factory with

a VFD, refer to the Vektor-HS SAVVE controls

Installation, Operation and Maintenance Manual

for electrical wiring and connection information.

8

Laboratory Exhaust System

®