Vektor-hs nozzle bearings, Damper actuators – Greenheck Fan Laboratory Exhaust System Vektor-HS User Manual

Page 10

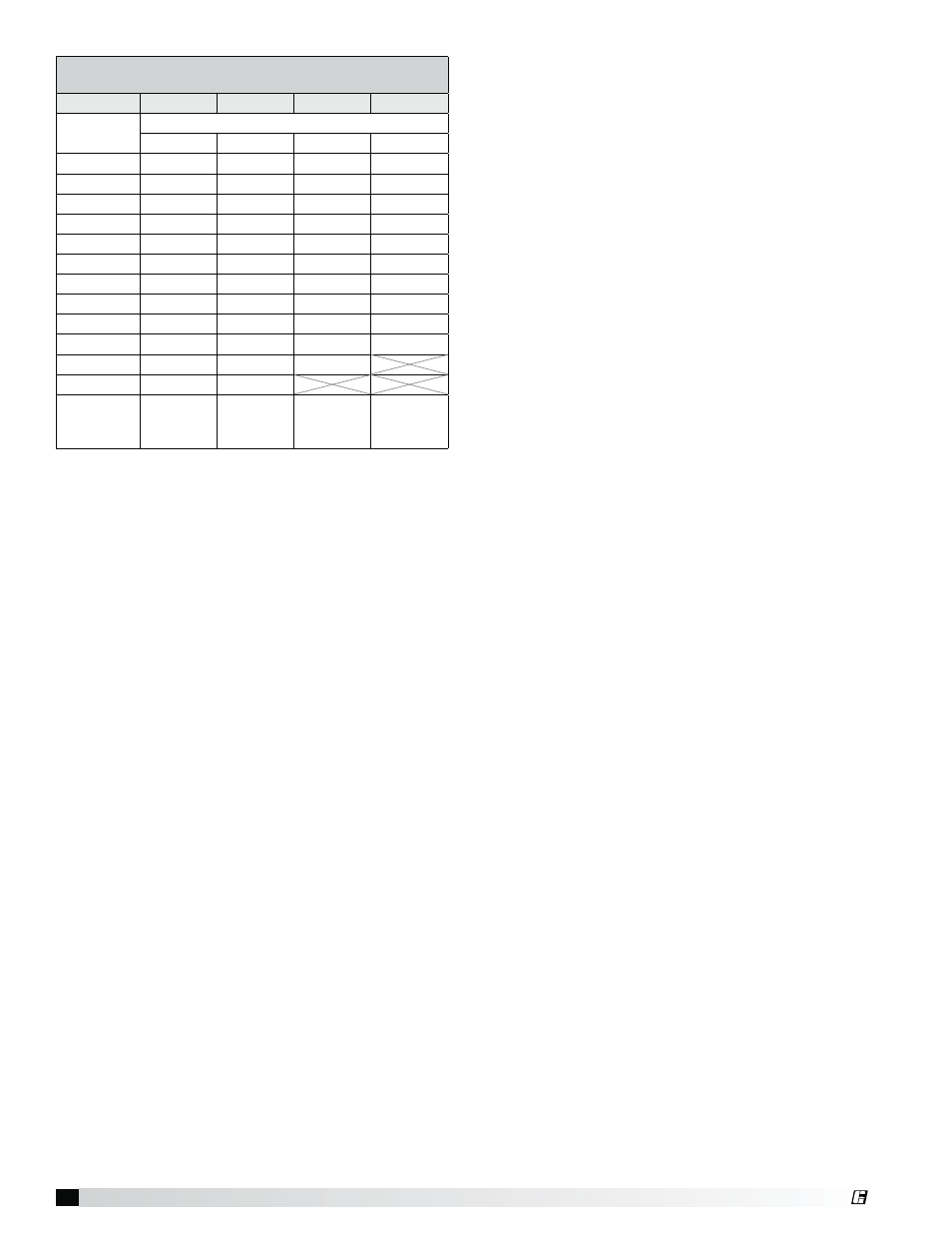

Recommended Bearing Lubrication Schedule

Relubrication Schedule in Months*

Fan Size

9 - 13

16 - 22

24

30 - 36

Fan

RPM

Bearing Bore (inches)

1

⁄

2

- 1

1

1

⁄

8

- 1

1

⁄

2

1

5

⁄

8

- 1

7

⁄

8

1

15

⁄

16

- 2

3

⁄

16

to 250

12

12

12

12

500

12

12

12

12

750

12

12

12

12

1000

12

12

12

12

1250

12

12

12

12

1500

12

12

12

10

2000

12

10

8

6

2500

12

7

5

4

3000

12

5

3

2

3500

12

3

2

0.75

4000

12

2

0.5

5000

12

1

Number

of shots of

grease**

4

8

8

10

* Lubrication interval is based on 12 hour per day operation and

maximum 160°F. housing temperature. For 24 hour per day

operation, the interval should be cut in half.

** Lubricant should be added with the shaft rotating and until clean

grease is seen purging from the bearing. The lubrication interval

may be modified based on the condition of the purged grease.

If bearing is not visible to observe purged grease, lubricate with

number of shots indicated for bore size.

Vektor-HS Nozzle Bearings

The bearings for the HS nozzle assembly are

permanently lubricated and do not require additional

grease.

Damper Actuators

Damper actuators, when supplied by manufacturer,

are designed to be maintenance free. No lubrication is

required.

10

Laboratory Exhaust System

®