V-belts – Grizzly G1012 User Manual

Page 18

-16-

G1012 18" Bandsaw

5.

To align pulleys, there is a variety of adjust-

ment. For example:

A. The band wheel pulley can be slid along

the shaft.

B. The three-step pulley can be adjusted

away from the base by doubling up a

washer.

C. The motor pulley can be turned around

and repositioned on the motor shaft.

Remember, the motor should remain level

after any adjustments.

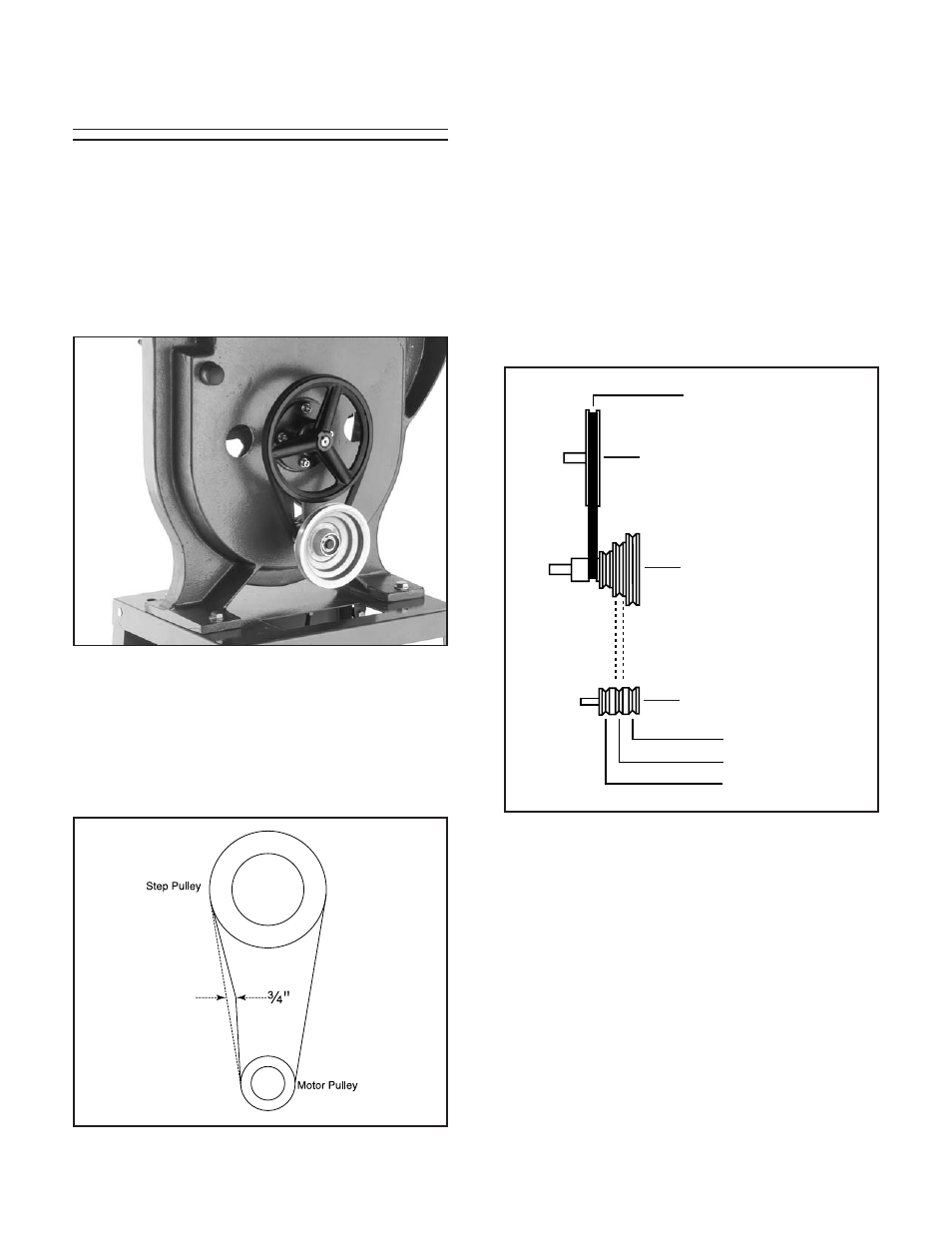

Figure 15. Pulley deflection w/moderate pressure.

V-Belts

3.

Adjust the motor back and forth until the V-

grooves line up with the V-grooves on the

three-step pulley.

4.

Slip either the 31" or 33" belt over the motor

pulley and the step pulley, depending on the

desired speed. For general woodworking, we

recommend setting the lower belt for the

fastest rate of speed. See

Figure 16 for

speeds.

You may have to back off the nuts on the

motor adjustment bolts to allow enough

motor swing to attach the belt.

A32 Belt

Bandsaw Pulley

Step Pulley

Motor Pulley

A33 Belt

2100 F.P.M.

A31 or A33 Belt

A31 Belt

3150 F.P.M.

2600 F.P.M.

Figure 16. Pulley speed chart.

In order to ensure proper power transmission

from motor to band wheels, the pulleys should be

aligned and the belts should have proper tension.

To begin pulley and belt assembly:

1.

Place the A32 belt in the wheel pulley groove

and the last groove in the stepped pulley as

shown in

Figure 14.

2.

Tension the belt by pushing the stepped pul-

ley down in the shaft slot. The belt deflection

should be approximately

3

⁄

4

" when you push

on the center of the belt (similar to

Figure

15) with your index finger.

Figure 14. Stepped pulley installed with wheel

pulley V-belt in place.