Servicing, Warning – Goodman Mfg R-410A User Manual

Page 22

SERVICING

22

S-1 CHECKING VOLTAGE

WARNING

1. Remove doors, control panel cover, etc. from unit being

tested.

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

2. Using a voltmeter, measure the voltage across terminals

L1 and L2 of the contactor for single phase units, and L3,

for 3 phase units.

3. No reading - indicates open wiring, open fuse(s) no power

or etc. from unit to fused disconnect service. Repair as

needed.

4. With ample voltage at line voltage connectors, energize

the unit.

5. Measure the voltage with the unit starting and operating,

and determine the unit Locked Rotor Voltage.

Locked Rotor Voltage is the actual voltage available at

the compressor during starting, locked rotor, or a stalled

condition. Measured voltage should be above minimum

listed in chart below.

To measure Locked Rotor Voltage attach a voltmeter to

the run "R" and common "C" terminals of the compres-

sor, or to the T

1

and T

2

terminals of the contactor. Start

the unit and allow the compressor to run for several sec-

onds, then shut down the unit. Immediately attempt to

restart the unit while measuring the Locked Rotor Volt-

age.

6. Should read within the voltage tabulation as shown. If

the voltage falls below the minimum voltage, check the

line wire size. Long runs of undersized wire can cause

low voltage. If wire size is adequate, notify the local

power company in regards to either low or high voltage.

Voltage

Min.

Max.

460

437

506

208/230

198

253

Unit Supply Voltage

Three phase units require a balanced 3 phase power supply to

operate. If the percentage of voltage imbalance exceeds 3%

the unit must not be operated until the voltage condition is

corrected.

Max. Voltage Deviation

% Voltage =

From Average Voltage X 100

Imbalance

Average Voltage

To find the percentage of imbalance, measure the incoming

power supply.

L1 - L2 = 240V

L1 - L3 = 232V Avg. V = 710 = 236.7

L2 - L3 = 238V 3

Total 710V

To find Max. deviation:

240 - 236.7 = +3.3

232 - 236.7 = -4.7

238 - 236.7 = +1.3

Max deviation was 4.7V

% Voltage Imbalance = 4.7

= 1.99%

236.7

If the percentage of imbalance had exceeded 3%, it must be

determined if the imbalance is in the incoming power supply or

the equipment. To do this rotate the legs of the incoming

power and retest voltage as shown below.

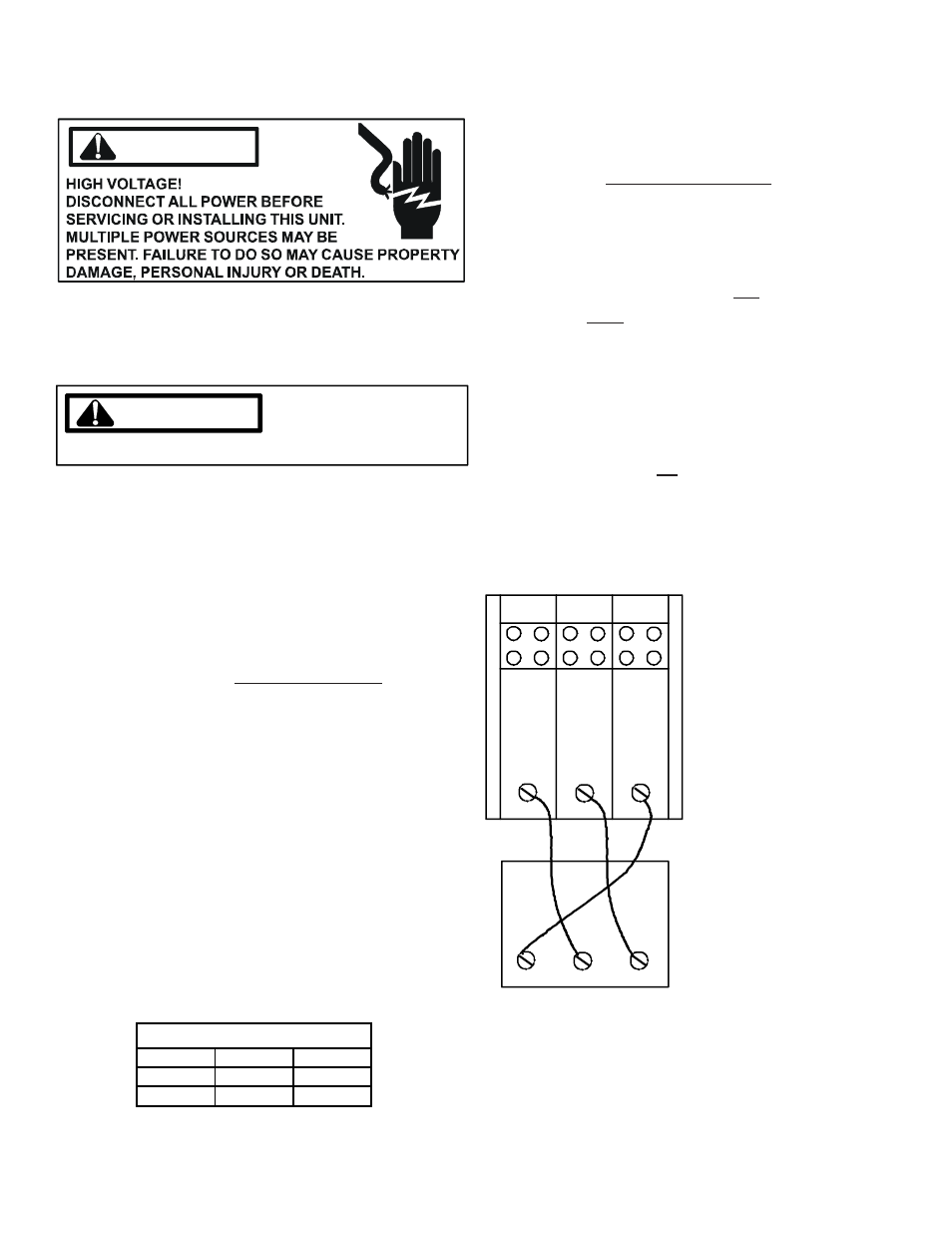

L1

L2

L3

L3

L2

L1

By the voltage readings we see that the imbalance rotated or

traveled with the switching of the incoming legs. Therefore the

power lies within the incoming power supply.

If the imbalance had not changed then the problem would lie

within the equipment. Check for current leakage, shorted mo-

tors, etc.

L1 - L2 = 240V

L1 - L3 = 227V

L2 - L3 = 238V

Rotate all 3 incoming

legs as shown.

L1 - L2 = 227V

L1 - L3 = 238V

L2 - L3 = 240V