Adjusting blade guide bearings – Grizzly Deluxe Bandsaw G0555LX User Manual

Page 28

-26-

G0555LX

(Mfg. Since 3/13)

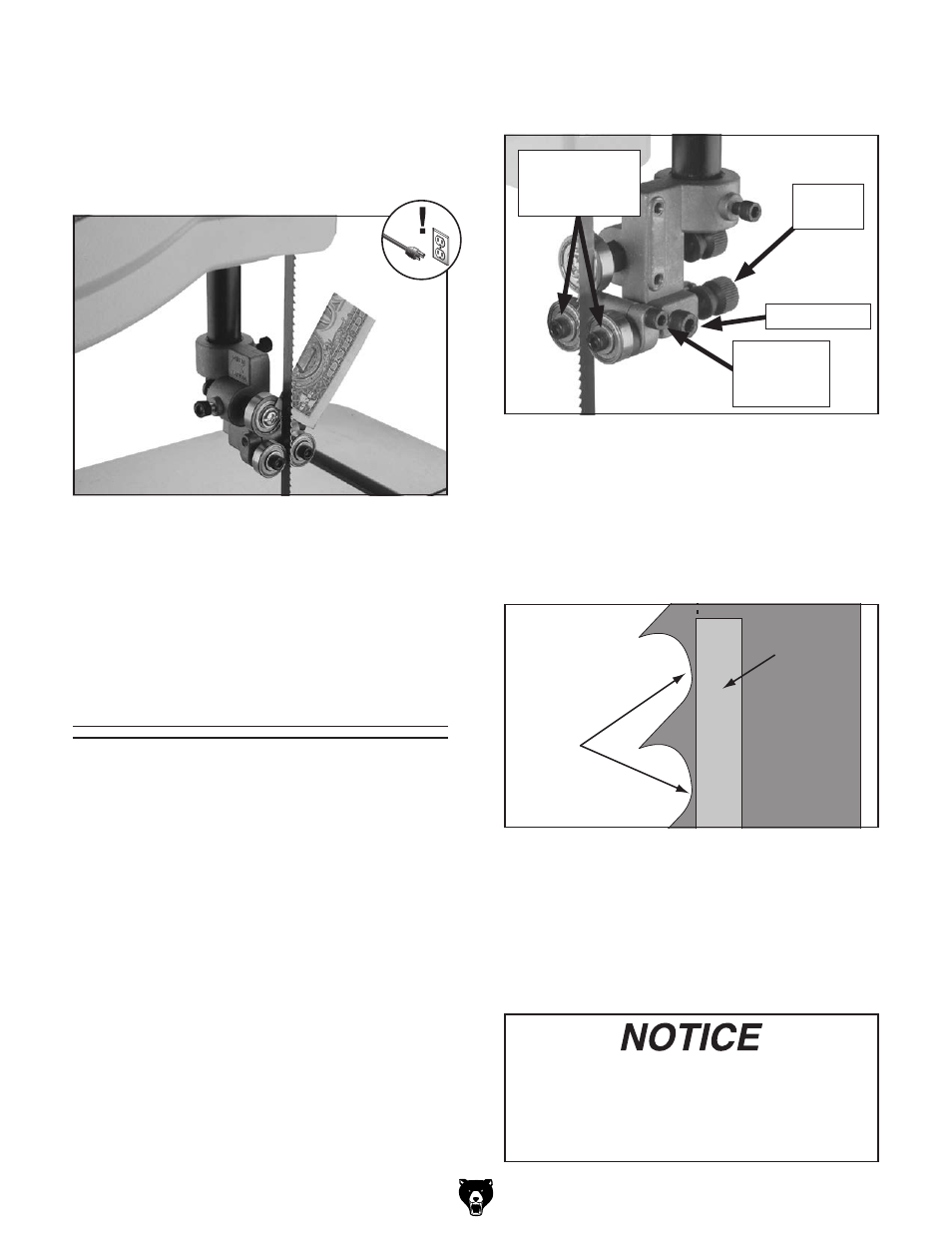

tip:

To quickly gauge this setting, fold a crisp

dollar bill in half twice (when folded tightly,

four thicknesses of a dollar bill is approxi-

mately 0.016"). Place the folded dollar bill

between the support bearing and the blade,

as shown in

Figure 32.

8. tighten the cap screw to lock the support

bearing in place.

figure 32. dollar bill folded twice to make a

quick 0.016" gauge.

2. Familiarize yourself with the blade guide con-

trols shown in

figure 33.

adjusting blade

guide bearings

properly adjusting the blade guides provides side-

to-side support to help keep the blade straight

while cutting.

there are blade guide bearings on the upper and

lower blade guide assemblies. both adjust in the

same manner.

important: The blade is tracking and tensioned

correctly before performing this procedure (see

tensioning blade on page 23).

tool needed

Qty

hex Wrench 4mm .............................................. 2

to adjust the upper and lower blade guides:

1. disConneCt bandsaW FroM poWer!

figure 33. blade guide bearing controls.

Cap screw

Knurled

Knob

locking

Cap screw

(1 of 2)

guide bearing

adjustment

Cap screws

3. loosen the cap screw shown in the figure

above, then use the knurled knob to adjust

the guide bearings laterally so the bearing

faces are just behind the blade gullet, as

illustrated in

figure 34, and re-tighten the

thumbscrew to secure the setting.

Blade

Guide

Bearing

Blade

Gullets

figure 34. blade guide bearing positioned just

behind the blade gullets.

note: With wider blades, it may not be possi-

ble to bring the guide bearings just behind the

blade gullets. Position them as far forward as

possible without allowing the guide bearing

housing to touch the back of the blade.

the set of the teeth increase the chance of

the bearings contacting the teeth during a

cutting operation as the set of the teeth is

wider than the blade. the support bearing

must be set to prevent this.