Introduction to fan selection – Greenheck Fan Fan Fundamentals 129 User Manual

Page 4

F A N F U N D A M E N T A l S

132

STATIC PRESSURE GUIDELINES

STATIC PRESSURE GUIDELINES

Nonducted

0.05 in. to 0.20 in.

Ducted

0.2 in. to 0.40 in. per 100 feet of

duct (assuming duct air velocity

falls within 1000-1800 feet per

minute)

Fittings

0.08 in. per fitting (elbow, register,

grill, damper, etc.)

Kitchen Hood

Exhaust

0.625 in. to 1.50 in.

Static pressure requirements are significantly affected

by the amount of make-up air supplied to an area.

Insufficient make-up air will increase static pressure

and reduce the amount of air that will be exhausted.

Remember, for each cubic foot of air exhausted, one

cubic foot of air must be supplied.

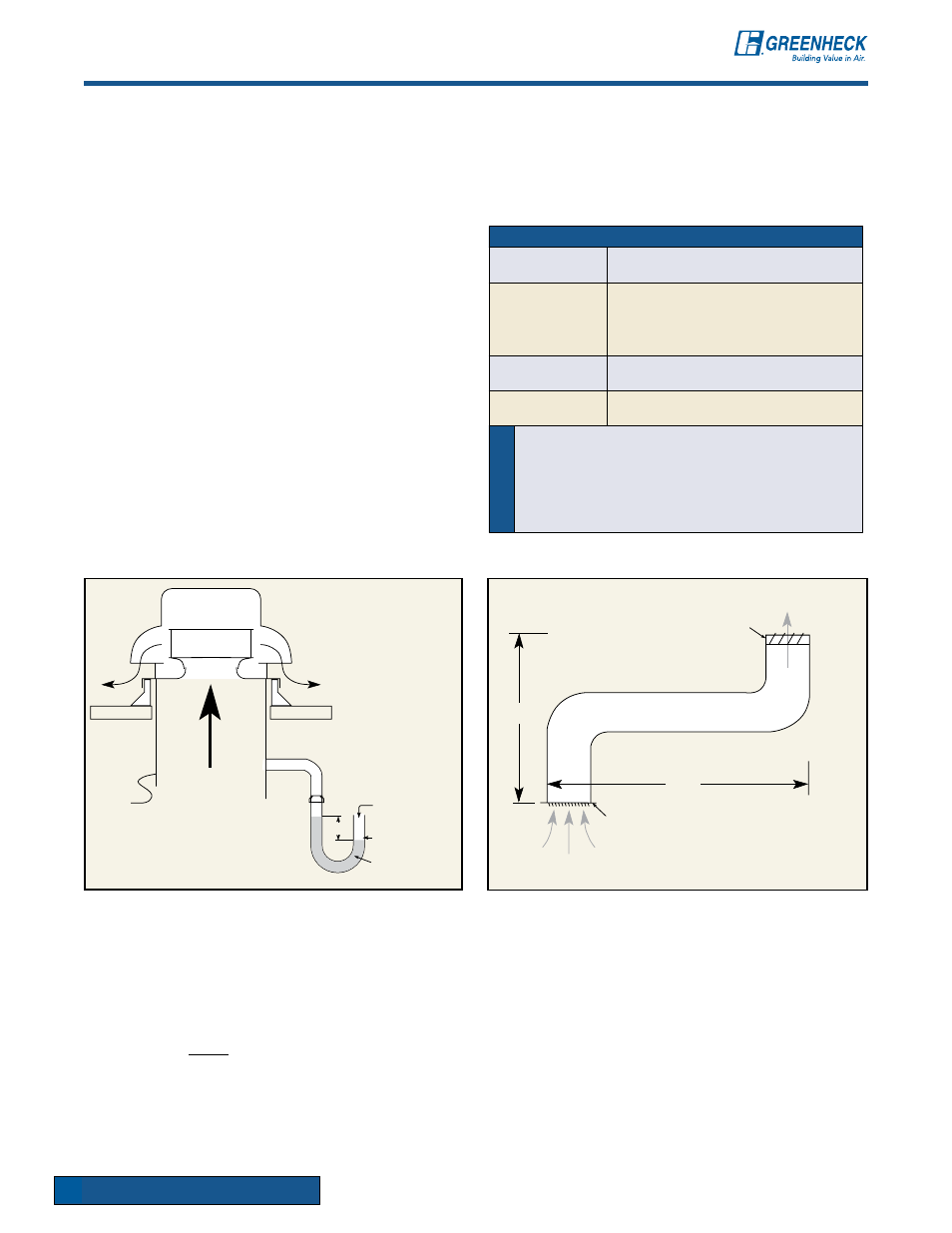

DETERMINING STATIC PRESSURE (Ps)

The pressures generated by fans in ductwork are

very small. Yet, accurately estimating the static

pressure is critical to proper fan selection.

Fan static pressure is measured in inches of water

gauge. One pound per square inch is equivalent

to 27.7 in. of water gauge. Static pressures in fan

systems are typically less than 2 in. of water gauge,

or 0.072 Psi. The drawing below illustrates how

static pressures are measured in ductwork with a

manometer.

A pressure differential between the duct and

the atmosphere will cause the water level in the

manometer legs to rest at different levels. This

difference is the static pressure measured in inches

of water gauge.

In the case of the exhaust fan below, the air is being

drawn upward through the ductwork because the

fan is producing a low pressure region at the top

of the duct. This is the same principle that enables

beverages to be sipped through a straw.

The amount of static pressure that the fan must

overcome depends on the air velocity in the

ductwork, the number of duct turns (and other

resistive elements), and the duct length. For

properly designed systems with sufficient make-up

air, the guidelines in the table below can be used for

estimating static pressure:

Duct

Airflow

Atmospheric

Pressure

Manometer

Water

1 in.

Airflow out of

restaurant

Grill

Damper

Airflow to

exhaust fan

4 ft.

6 ft.

Ductwork

Exhaust Fan

* nOTE: For convenience in using selection charts, round this value up to the nearest 1/8 in., which would be 0.50 Ps.

IMPOR

TANT!

Introduction to FAN SELECTION

To calculate the system losses, one must know the

ductwork system configuration (see Ductwork figure).

This duct is sized for air velocities of 1400 feet per

minute. Referring to the static pressure chart, that will

result in about 0.3 in. per 100 feet. Since we have

10 feet of total ductwork, our pressure drop due to

the duct is:

There is also a 0.08 in. pressure drop for each

resistive element or fitting. For this example, there

are 5 fittings: one grill, two duct turns, one damper

and louver in the wall of the office. The total pressure

drop for fittings is:

5 x 0.08 in. = 0.4 in.

Therefore, the total pressure drop is:

0.03 in. + 0.40 in. = 0.43 in.*

.3 in.

x

10 ft.

= .03 in.

100 ft.