Maintenance, Preventive maintenance schedule – Graco HIGH-FLO 311211L User Manual

Page 13

Maintenance

311211L

13

Maintenance

Preventive Maintenance

Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Your maintenance schedule should include the follow-

ing:

Flushing

Air Line Filter

Drain and clean as necessary.

Hydraulic Power Supply Check

Carefully follow the hydraulic power supply manufac-

turer's recommendations on reservoir and filter cleaning,

and periodic changes of hydraulic fluid.

Mix Tank Volume

Don't let the mix tank run dry. When the tank is empty,

the pump demands more power as it tries to suck in

some fluid. This causes the pump to run too fast, which

can seriously damage the pump.

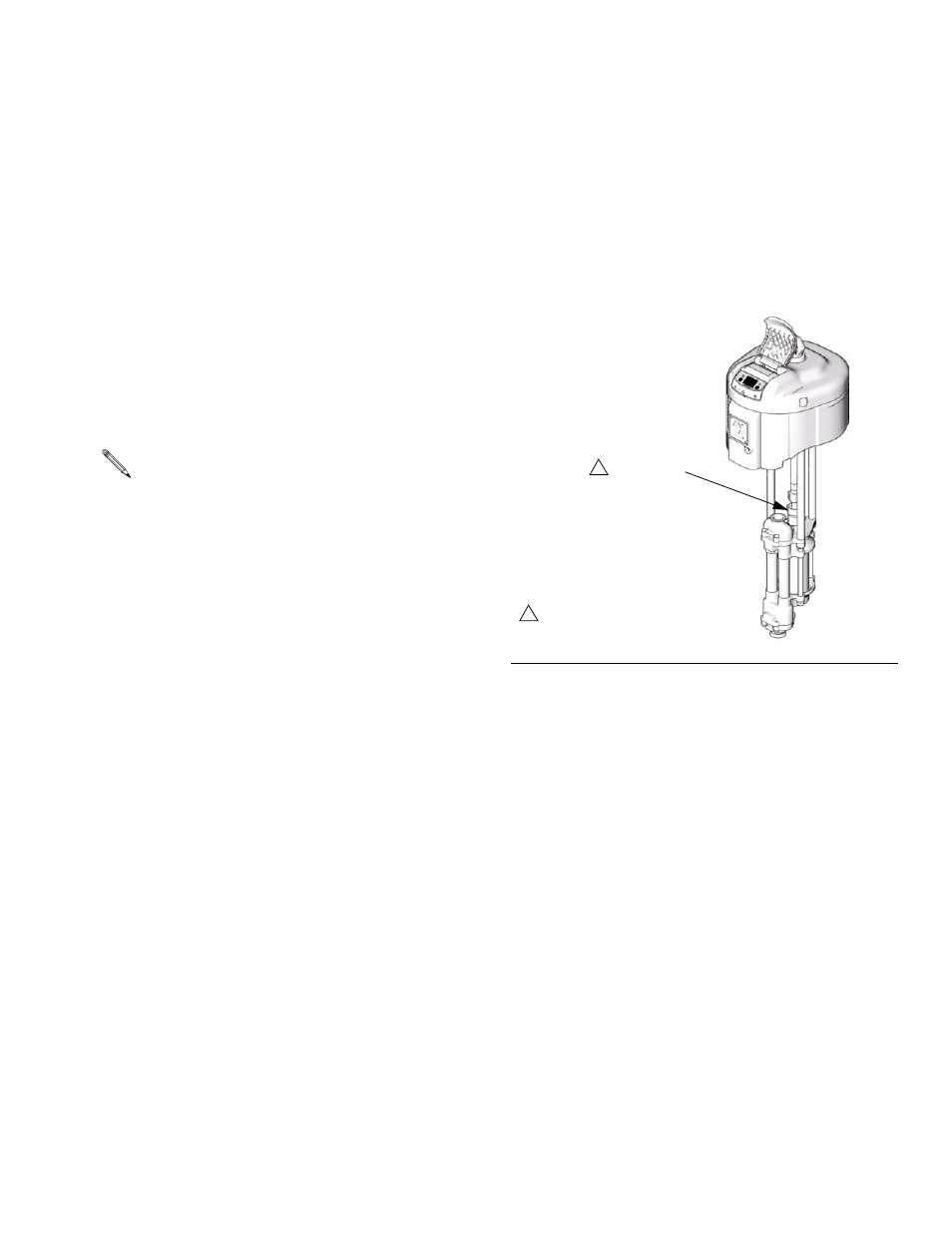

Packing Nut Tightness

Check the packing nut (21) tightness every few days at

startup and then weekly throughout the life of the throat

seal. The packing nut should be tight enough to stop

leakage, but no tighter. See F

To check the adjustment of the packing nut, stop the

pump and relieve fluid pressure. Loosen the packing nut

until it turns freely. Tighten the nut firmly and then turn

the nut another 1/4 turn. If you have a torque wrench,

tighten the packing nut to 30 ft-lb (40 N•m), then back off

and re-tighten to 15-20 ft-lb (20-27 N•m).

Excessive Leaking at Throat

If you see excessive leaking at the throat, tighten the

packing nut (21), see F

. 4. If this does not fix the prob-

lem, replace the throat packings, piston rod, or both See

manual 311690.

•

Flush before shutting down the system for an

extended period of time.

•

Flush before repairing the pump, if possible.

•

Flush before fluid can dry out, settle, or set up

in the equipment.

F

IG

. 4

NXT Air-Powered

Pump Shown

TI8354a

1

Torque to 15-20 ft-lb (20-27 N•m).

1

packing nut