Pgt16 aeroderivative gas turbines – GE Gas Turbine User Manual

Page 14

14

GE Energy Gas Turbines

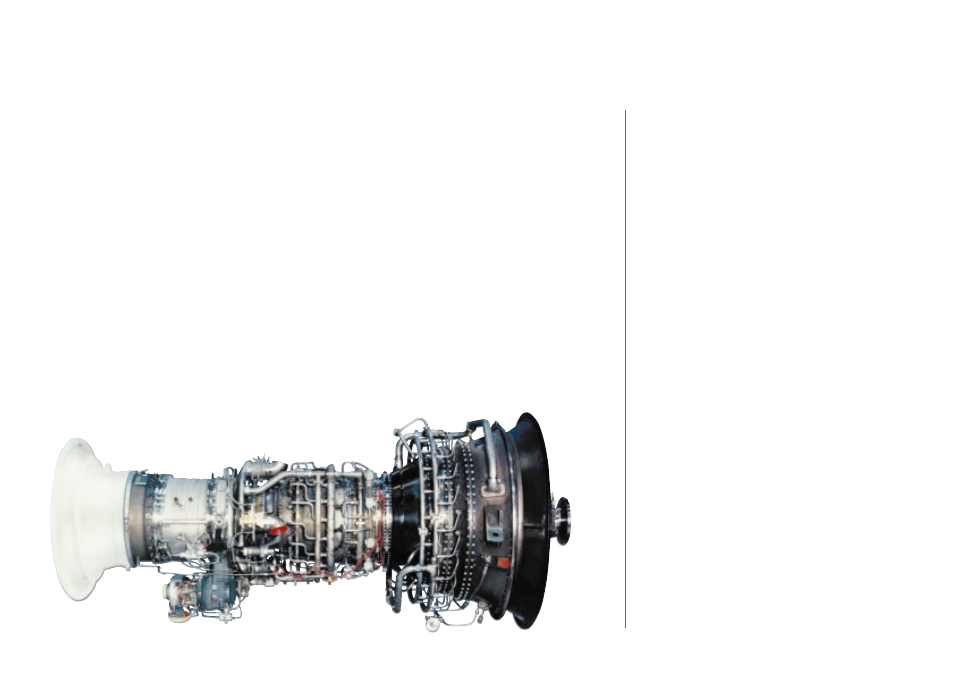

The PGT16 gas turbine consists of the twin spool GE Aeroderivative LM1600 Gas Generator coupled

with a rugged, industrial power turbine designed by GE Energy’s Oil & Gas businesses. The LM1600

Gas Generator is derived from the F404 turbofan aircraft engine.

The power turbine of the PGT16 gas turbine is identical to that of the PGT10 heavy duty, high

efficiency gas turbine which has been in operation for more than half a million hours.

The power turbine shaft speed (7900 RPM) is optimized for direct coupling to pipeline, injection and

process centrifugal compressors with a speed range that matches most operating requirements

encountered in oil & gas applications. For generator drive applications the PGT16 synchronously

coupled to a generator with a speed reduction gear is a highly flexible turbogenerator which can be

operated as a simple cycle or in combined or cogeneration cycle applications with an electrical

efficiency close to 50%.

GENERAL SPECIFICATIONS

Compressor

-

Twin spool axial compressor (3 stage LP compressor,

7 stage HP compressor)

-

Pressure ratio 20.1:1

Combustion

-

Annular combustion chamber (18 fuel nozzles)

Turbine

-

Twin Spool Gas Generator turbine (1 stage HP

turbine, 1 stage LP turbine)

-

Two stage Power turbine with variable angle first

stage nozzles

Package

-

Completely mounted on a single base plate

-

The enclosure is integral with the base plate

providing maximum accessibility for maintenance

of the gas turbine and auxiliaries

Emission Control

-

Steam or water injection systems for NOx abatement

-

Dry Low Emission (DLE) combustion system

PGT16 Aeroderivative Gas Turbines

PGT16 Gas Turbine