4 synthesizer circuit, 7 servo control – FUJITSU C141-E090-02EN User Manual

Page 57

C141-E090-01EN

4 - 12

4.6.4

Synthesizer circuit

The drive uses constant density recording to increase total capacity. This is different from the

conventional method of recording data with a fixed data transfer rate at all data area. In the

constant density recording method, data area is divided into zones by radius and the data

transfer rate is set so that the recording density of the inner cylinder of each zone is nearly

constant. The drive divides data area into 15 zones to set the data transfer rate. Table 4.2

describes the data transfer rate and recording density (BPI) of each zone.

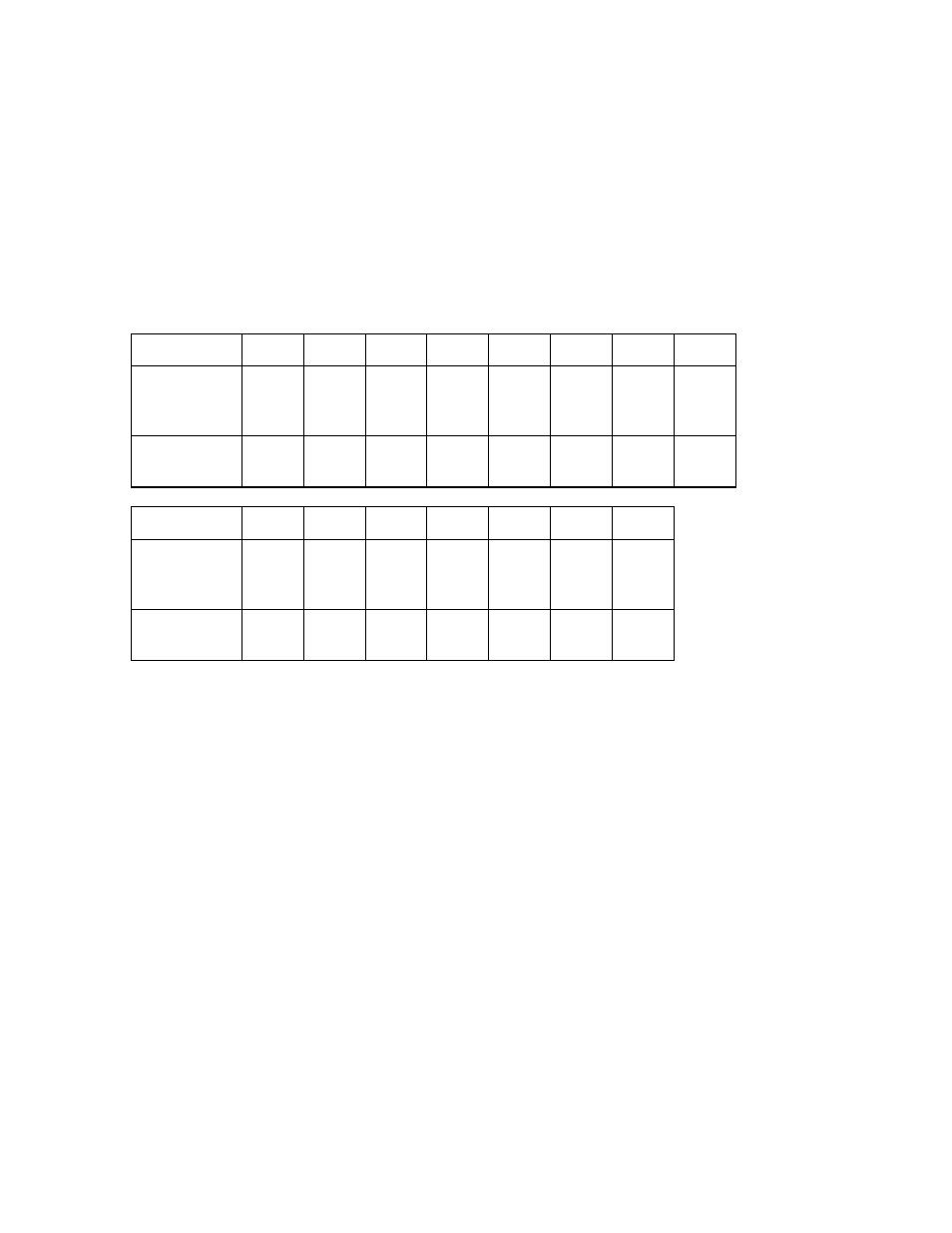

Table 4.2

Write clock frequency and transfer rate of each zone

Zone

0

1

2

3

4

5

6

7

Cylinder

0

to

1230

1231

to

2560

2561

to

3820

3821

to

5610

5611

to

6510

6511

to

6940

6941

to

8640

8641

to

9530

Transfer rate

[MB/s]

40.69

40.69

39.67

38.08

37.21

36.78

34.90

33.89

Zone

8

9

10

11

12

13

14

Cylinder

9531

to

10870

10871

to

11530

11531

to

12200

12201

to

13300

13301

to

14030

14031

to

15160

15161

to

15870

Transfer rate

[MB/s]

32.29

31.42

30.58

29.10

28.09

26.49

24.54

The MPU transfers the data transfer rate setup data to the RDC that includes synthesizer circuit

to change the data transfer rate.

4.7

Servo Control

The actuator motor and the spindle motor are submitted to servo control. The actuator motor

is controlled for moving and positioning the head to the track containing the desired data. To

turn the disk at a constant velocity, the actuator motor is controlled according to the servo data

that is written on the data side beforehand.