J. routine maintenance, Components, Figure 16 – Friedrich HEAT PUMPS User Manual

Page 22

22

920-087-04

J. Routine Maintenance

1. Clean the unit air intake fi lter at least every 300 to 350 hours

of operation. Clean the fi lters with a mild detergent in warm

water and allow to dry thoroughly before reinstalling.

2. The indoor coil (evaporator coil), the outdoor coil (condenser

coil) and base pan should be inspected periodically (yearly

or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper,

etc.). Clean the coils and base pan with a soft brush and

compressed air or vacuum. If using a pressure washer, be

careful not to bend the aluminium fi n pack. Use a sweeping

up and down motion in the direction of the vertical aluminum

fi n pack when pressure cleaning coils. Cover all electrical

components to protect them from water or spray.

Before reinstalling the chassis in the sleeve, inspect the

indoor blower housing, blower wheel, condenser fan blade,

and condenser shroud periodically (yearly or bi-yearly) and

clean of all debris (lint, dirt, mold, fungus, etc.) Clean the

blower housing area and blower wheel with an antibacterial

/ antifungal cleaner. Use a biodegradable cleaning agent

and degreaser on condenser fan and condenser shroud.

Use warm or cold water when rinsing these items. Allow

the unit to dry thoroughly, inspect all gasket material for

deterioration (replace as necessary), and then reinstall the

chassis in the sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils

or base pan. Use a biodegradable cleaning agent and

degreaser.

NOTE: Units are to be inspected and ser viced by qual i fi ed service per son nel only.

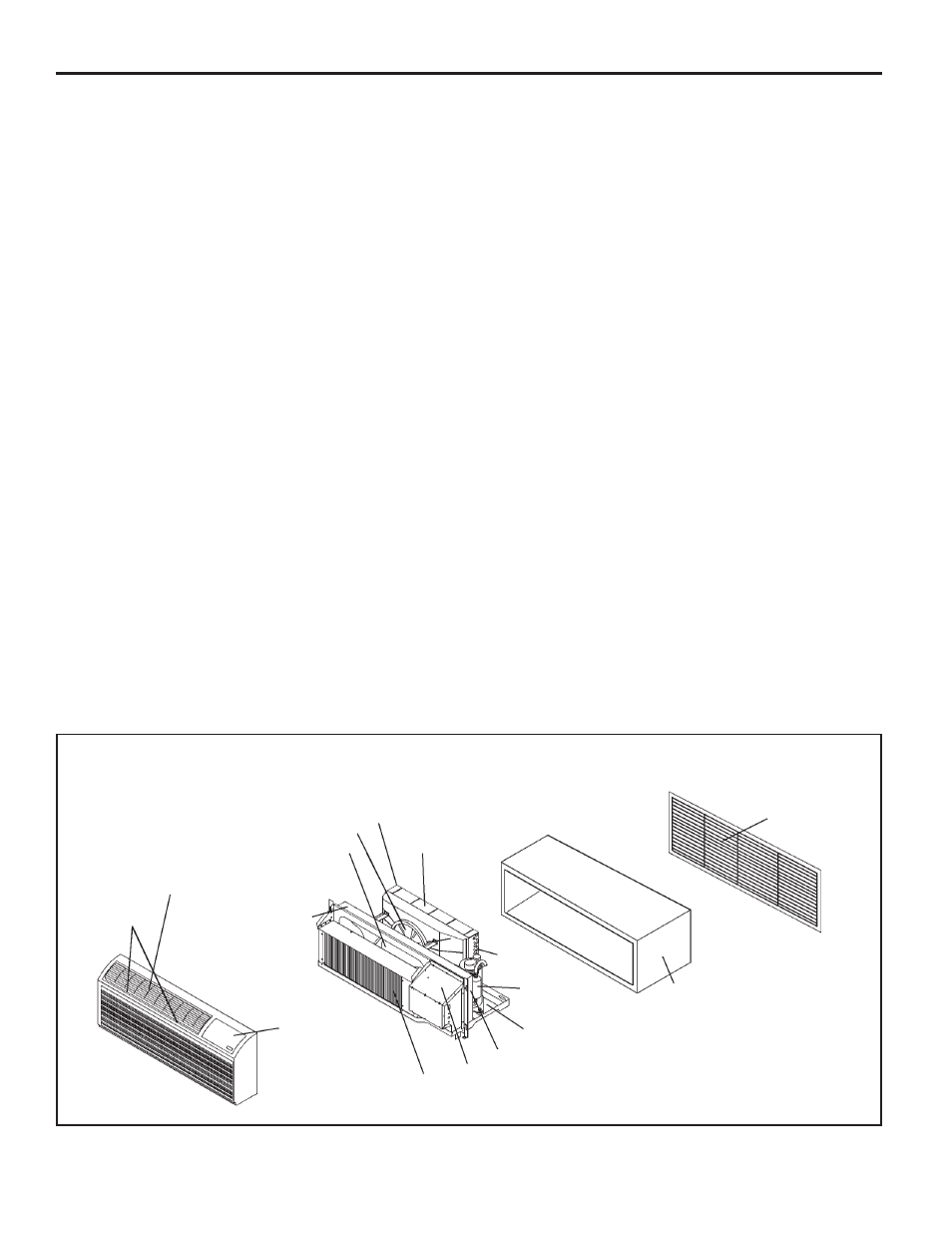

Discharge Air Grille

Filters

Return Air

Grille

Front Cover

Evaporator Coil

Indoor Blower

Housing

Gasket

Condenser Shroud

Condenser Fan Blade

Indoor Blower

Innerwall

Basepan

Outdoor Grille

Wall Sleeve

Control Panel

Condenser Gasket

Compressor

3. Periodically (at least yearly or bi-yearly): inspect all control

components, both electrical and mechanical, as well as the

power supply. Use proper testing instruments (voltmeter,

ohmmeter, ammeter, wattmeter, etc.) to perform electrical

tests. Use an air conditioning or refrigeration thermometer

to check room, outdoor and coil operating temperatures.

Use a sling psychrometer to measure wet bulb temperatures

indoors and outdoors.

4. Inspect the surrounding area (inside and outside) to ensure

that the units' clearances have not been compromised or

altered.

5. Inspect the sleeve and drain system periodically (at least

yearly or bi-yearly) and clean of all obstructions and debris.

Clean both areas with an antibacterial and antifungal

cleaner. Rinse both items thoroughly with water and ensure

that the drain outlets are operating correctly. Check the

sealant around the sleeve and reseal areas as needed.

6. Clean the front cover when needed. Use a mild detergent.

Wash and rinse with warm water. Allow them to dry

thoroughly before reinstalling them in the chassis.

Components

Figure 16

- 7,200 BTU Packaged Terminal Air Conditioner Warranty 920-087-09 (12/10) 24,000 BTU/h A-SERIES 9 ZoneAire Series 42 Inch Packaged Terminal Air Conditioner Warranty ZoneAire Series 42 Inch Packaged Terminal Air Conditioner Warranty Guide 7,200 BTU Packaged Terminal Air Conditioner Installation and Operation Manual 7,200 BTU Packaged Terminal Air Conditioner Product Profile