9500 valve, Caution, Instruction manual – Fisher 9500 User Manual

Page 4

9500 Valve

Instruction Manual

Form 2433

November 2007

4

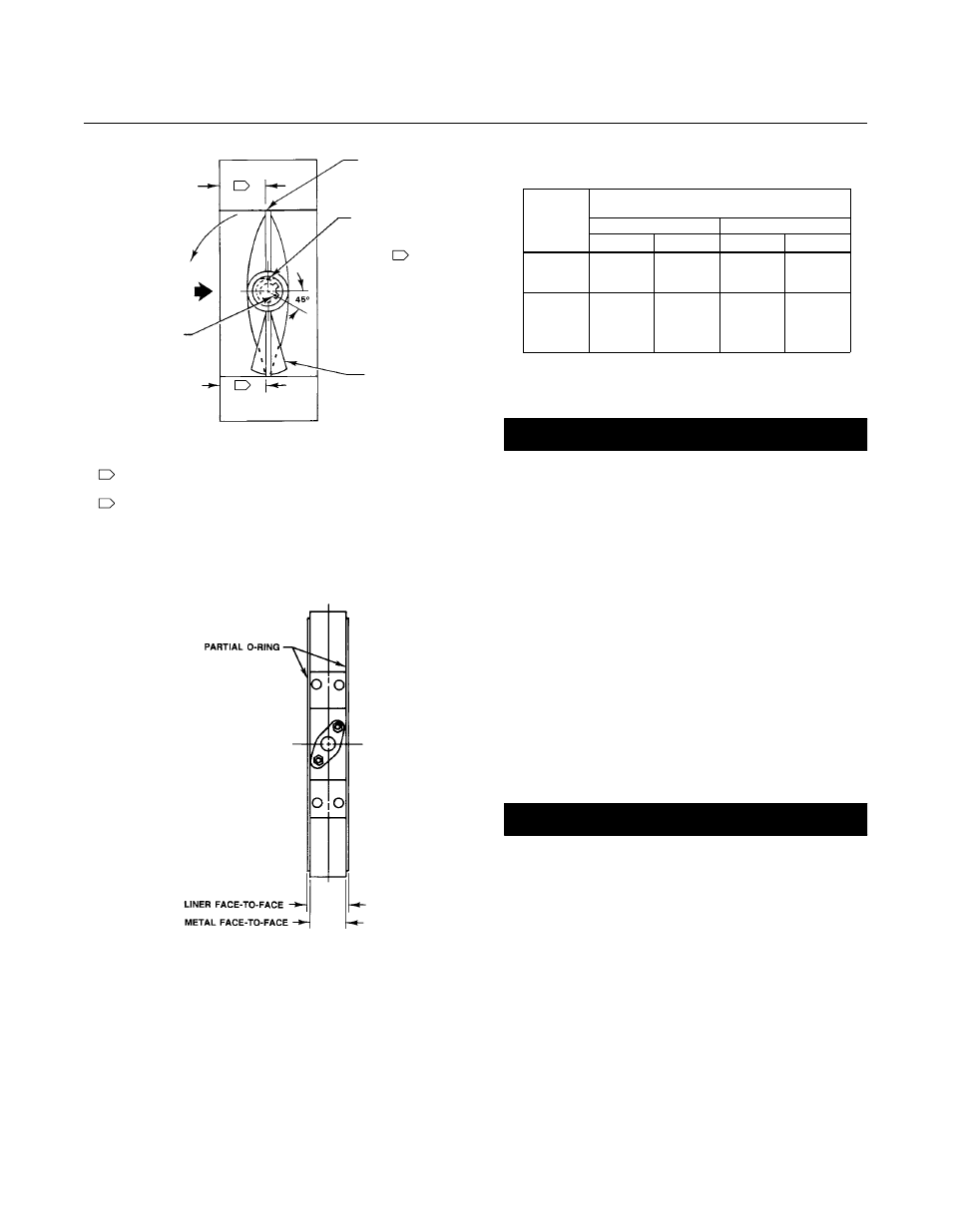

Figure 2. Valve Shaft Marking

A2755-1/IL

LOCATION OF

INDEX MARK

ON END OF

VALVE SHAFT

TAIL OF

Fishtail

DISC

LOCATION OF

FLAT SPOT

ON VALVE

SHAFT

NOSE OR

LEADING

EDGE OF

DISC

OPEN

FLOW

WITH SPLINED

VALVE SHAFT

EQUAL MEASUREMENTS BETWEEN VALVE FACE AND DISC

EDGE AT TOP AND BOTTOM ENSURE FULLY CLOSED DISC.

FOR Fishtail DISC, PARTIAL KEYWAY OR FLAT SPOT IS ON

SAME SIDE AS NOSE OF DISC.

1

1

2

1

2

Figure 3. Partial O-Ring Location

A6017/IL

hardware or packing rings, or when

loosening the packing box pipe plug.

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve body,

and drain the process media from both sides of the

valve. If continuous operation is required during

inspection or maintenance, install a three-valve

bypass around the control valve assembly.

Table 3. Maximum and Minimum Allowable

Mating Flange Diameters

VALVE

MAXIMUM AND MINIMUM DIAMETER OF MATING

PIPING OR FLANGES

VALVE

SIZE, NPS

Minimum

Maximum

SIZE, NPS

mm

Inches

mm

Inches

2

3

4

30

64

89

1.20

2.50

3.50

64

92

117

2.50

3.62

4.62

6

8

10

12

145

196

246

297

5.70

7.70

9.70

11.70

171

222

273

330

6.75

8.75

10.75

13.00

2. Be certain the pipeline flanges are in line with

each other and supported.

CAUTION

To avoid damaging valve seating

surfaces, make sure the adjacent

piping is free of pipe scale, welding

slag, and any other damaging material.

3. Inspect the valve body to be sure it is free of

foreign material. Make sure the adjacent piping is

free of pipe scale, welding slag, and any other

material that could damage valve seating surfaces.

4. Measure to be sure the distance between the

pipeline flanges is approximately 1/4 inch greater

than the valve face-to-face dimension. This will

ensure easy installation without distorting the liner

(figure 3).

5. For conventional discs, flow may be in either

direction; for Fishtail discs, flow must be such that

the tail of the disc (as shown in figure 2) will rotate

into the downstream side of the valve.

CAUTION

To avoid damaging valve parts,

observe the following precautions

before inserting the valve in the line.

a. The inside diameter of the mating piping or

flanges must be large enough to allow the valve

disc to rotate freely into the upstream and

downstream piping, or the disc could be

damaged. Do not use piping or flanges having an

inside diameter smaller than the minimum shown

in table 3.

b. The inside of the mating flange must also be

small enough to be in full contact with the partial

O-rings on the liner faces. Leakage through the

flange connections and damage to the liner could