Notice, Figure f, Figure 2 figure 3 – Friedrich HAZARDGARD SH15 User Manual

Page 11: Figure 1, Figure 4

11

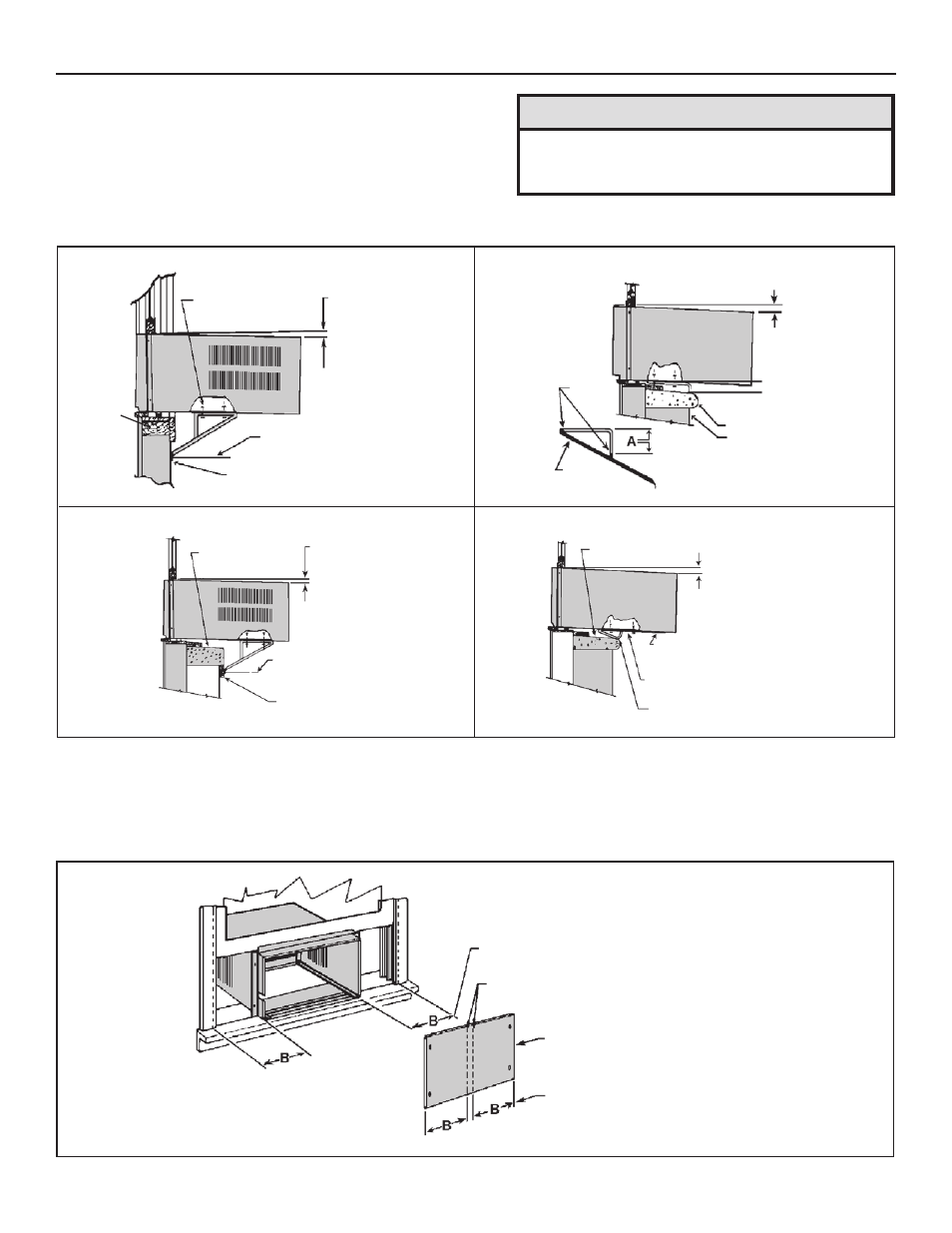

Figure F

The illustrations below show a standard frame construction

installation as well as some suggested ways of adapting the

support bracket to thick walls and large brick ledges.

Figure 2

Figure 3

SUBTRACT 1/8" (3 MM) FROM

DIMENSION "B" AND MEASURE FROM

THE EDGE OF THE WINGBOARD (ITEM

# 8), MARK AND CUT WITH A SAW.

STEP 4

CUT WINGBOARD PANELS: Measure and cut the wingboard panels from the supplied masonite (Item #8) to fit the

spaces between the side window channels and the sides of the cabinet (See Figure F).

NOTE: AFTER CUTTING PANELS, MAKE A TRIAL TEST TO SEE IF THEY FIT THE SPACE WITH ABOUT

1/8" CLEARANCE BEFORE GOING TO STEP 5.

Typical Installation Sill Plate

Shell Installation: Thick Wall

10 - 24 SCREW

10 - 24 FLAT NUT

3/8" (10 MM)

SLOPE DOWN

#12A X 2" SHEET METAL SCREW

1" X 2" OR 2" X 4" SPACER BETWEEN WALL

AND BRACKET SHOULD BE USED ON ALU-

MINUM, ASBESTOS OR VINYL SIDING

Figure 1

STONE LEDGE

OUTSIDE WALL

CUT TO FIT DIMENSION "A"

AND BEND DOWN TO FOR A

VERTICAL LEG

DISCARD

SHADED AREA

BRICK LEDGE

WOOD

LEDGE

3/8" (10 MM)

SLOPE DOWN

3/8" (10 MM)

SLOPE DOWN

#12A X 2" SHEET METAL SCREW

2" X 4" SPACER

MEASURE DISTANCE "B" TO THE INSIDE

OF THE CHANNEL ON EACH SIDE

CUT HERE AND DISCARD THE CENTER

WASTE MATERIAL

WINGBOARD

CUT

HERE

Figure 4

STONE LEDGE

3/8" (10 MM) SLOPE DOWN

STRAIGHTEN TAB TO LAY FLAT ALONG

THE BOTTOM RAIL OF THE SHELL.

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL.

ADJUST IN OR OUT TO

REST ON THE LEDGE

920-024-07

NOTICE

Instructions for mounting sleeve with slope must be obser-

ved to prevent entry of water into room.

Failure to follow instructions can result in property damage.