Venting installation – FMI MASONRY FIREBOX MM33 User Manual

Page 16

www.fmiproducts.com

125160-01A

16

venting installation

Continued

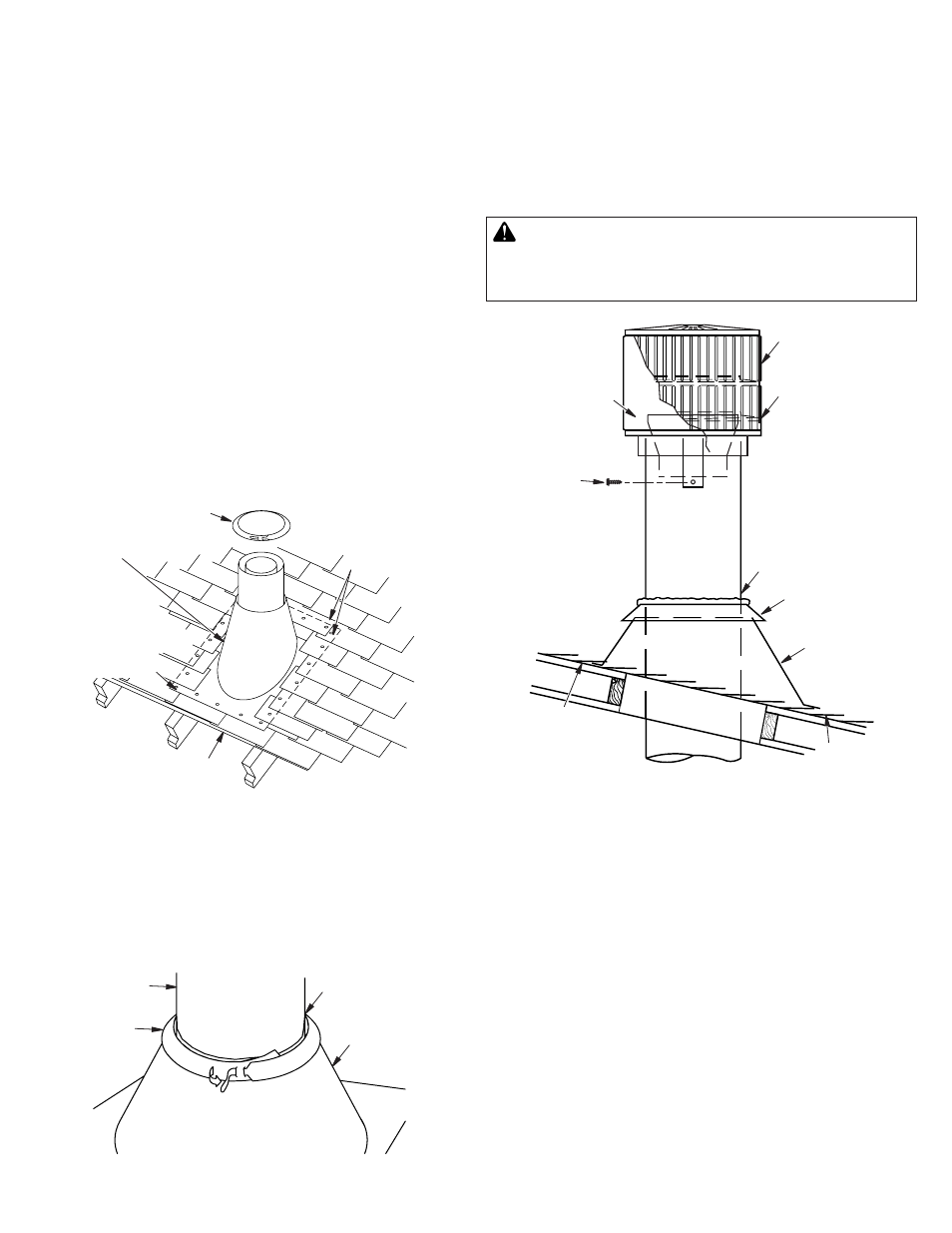

Nail Only

Outer

Perimeter

of Flashing

Storm

Collar

Flashing

Cone

Underlap Shingles

at Bottom

Overlap Shingles

Top and Sides

Only

Figure 21 - Flashing Installation

FlasHInG InsTallaTIon (V6F-10dM oR

V12F-10dM)

Determine the flashing to be used with the roof open-

ing chart. Slide flashing over pipe until base is flat

against roof. Replace as many shingles as needed

to cover exposed area and flashing base. Secure in

position by nailing through shingles (see Figure 21).

DO NOT NAIL THROUGH FLASHING CONE.

Installing Flashing on a Metal Roof

When installing the flashing on a metal roof, it is re-

quired that putty tape be used between the flashing

and the roof. The flashing must be secured to the

roof using #8 x 3/4" screws and then sealed with roof

coating to prevent leakage through the screw holes.

A roof coating must also be applied around the pe-

rimeter of the flashing to provide a proper seal.

storm Collar Installation (sC2-1)

Place storm collar over pipe and slide down until it is

snug against the open edge of the flashing (see Figure

22). Apply waterproof caulk around the perimeter of

the collar to provide a proper seal.

Figure 22 - Storm Collar

Chimney

Pipe

Waterproof

Caulk

Storm

Collar

Flashing

TeRMInaTIons/sPaRK aRResToR

The fireplace system must be terminated with the

listed round top or chase terminations. In any case,

refer to the installation instructions supplied with the

termination.

CaUTIon: do not seal openings on the rooftop

flashing. Follow the installation instructions

provided with the termination being used.

Secure

Termination

to Outer Pipe

with 3 Screws

RTL-12D

Level of

Flue Gas

Outlet

Waterproof

Caulking

Storm

Collar

Flashing

Figure 23 - Termination

Overlap

Shingles (Top

and Sides of

Flashing Base)

CHase InsTallaTIons

Instructions for chase installations are included with

the chase style termination chosen. In a multiple

chase installation, be sure to provide adequate dis-

tance between terminations to prevent smoke spill-

age from one termination to another. We suggest

that terminations be separated at least 24", center to

center and stacked at a vertical height difference of

18" (see Figure 24, page 17).

Stainless

Inner Flue

Pipe

Underlap

Shingles