Venting installation – FMI MASONRY FIREBOX MM33 User Manual

Page 13

www.fmiproducts.com

125160-01A

13

been built at the correct heights; system drafts

caused by faulty mechanical systems; adverse

weather conditions or any other environmental

situations over which the manufacturer has no

control.

Inspect all fireplace & chimney components for

5)

evidence of damage prior to starting installation.

Consult your local distributor for replacement

parts if necessary.

Under no circumstances should you make any

6)

adjustments or modifications to the chimney

system during the installation procedure. If

you do, you are not only liable for negating the

warranty, but you could very well cause a serious

malfunction of the fireplace. You must follow these

chimney instructions.

Caution is urged if it is decided to add insulation

7)

material to any part of the Grand Meridian Fireplace

or Chimney system, be certain that the insulation

material is kept at least 2” away from any part of

the system. When using insulation or vapor barrier

materials, cover with a layer of plywood, particle

board or gypsum board to maintain the specified

2” clearance.

Air spaces around firebox must remain open.

8)

DO NOT fill these open spaces with insulation or

packing material of any kind.

CHIMneY PIPe

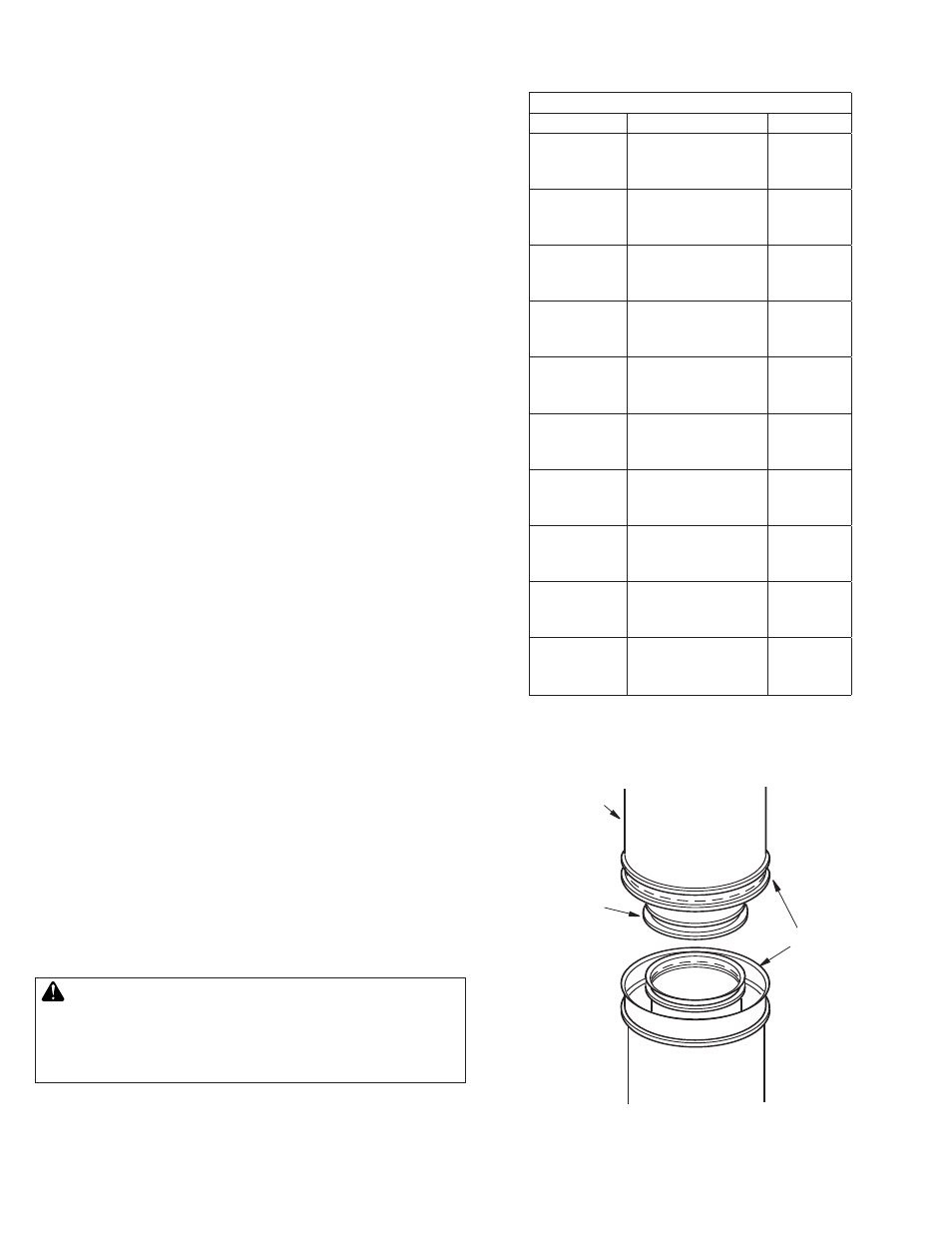

The FMI PRODUCTS, LLC chimney system consists

of 12", 18", 24", 36" and 48" snap-lock, double-wall

pipe segments, planned for maximum adaptability to

individual site requirements. Actual lengths gained

after fitting overlaps must be taken into consideration

(lineal gain) and are given in the lineal gain chart (see

Figure 14). Lineal Gain is the actual measurable length

of a part after two or more parts are connected.

WaRnInG: The opening in the collar around

the chimney at the top of the fireplace must not

be obstructed. never use blown insulation to

fill the chimney enclosure.

venting installation

Continued

Figure 14 - Lineal Gain

lIneal GaIn

PaRT no. desCRIPTIon GaIn

MM33

Fireplace

54 ⅝"

MM39

MM44/49

Fireplace

63 ½”

MM63

Fireplace

73”

12-12DM

Pipe Section

10

5

/

8

"

18-12DM

Pipe Section

16

5

/

8

"

24-12DM

Pipe Section

23

5

/

8

"

36-12DM

Pipe Section

34

5

/

8

"

48-12DM

Pipe Section

46

5

/

8

"

RLT-12D

Round

Termination

7

3

/

4

"*

STL-12D

Square Chase-

Top with Slip

Section

7" to 15"*

* The lineal gain for the terminations is

measured to the flue gas outlet height.

Hemmed End

12

3

/

8

"

Stainless

Inner Pipe

15" Galvanized

Outer Pipe