Installation, Aeration adjustment, High elevation – Hampton Direct H25-NG1 User Manual

Page 27: Gas connection, Cathedral ceilings

Hampton

®

H25-1 Direct Vent Freestanding Gas Stove

27

AERATION

ADJUSTMENT

The burner aeration is factory set but may need

adjusting due to either the local gas supply, air

supply or altitude.

Natural Gas

3-16" (4.76 mm)

Propane 1/4"

(6.4

mm)

The aeration adjustment gears are located on

the right side of the burner box. Remove the

Hampton

®

Logo plate on the right side of the

unit to access the adjustment gears.

SYSTEM DATA - H25

For 0 to 4500 feet altitude

Burner Inlet Orifi ce Sizes:

Natural Gas

Propane

Burner #42

#54

Max. Input Rating

-

Natural

Gas

25,000

Btu/h

-

Propane

23,000

Btu/h

Min. Input Rating

-

Natural

Gas

12,500

Btu/h

- Propane

11,500 Btu/h

Supply Pressure

Natural Gas

min.

5.0" w.c.

Propane

min. 12.0"

w.c.

Manifold Pressure

Natural Gas

3.8"

+/- 0.2" w.c.

Propane

11"

+/- 0.2" w.c.

Note: If you are using a 6" square support

you may fi nd it diffi cult to screw it

in place because it is fairly small

inside.

Simpson

Dura-Vent

has

provided

angle

brackets with this support which can be

screwed to the outside of the support

box and nailed to surrounding framing as

required. Use a minimum of four #8 x 1/2"

screws per bracket. In some cases these

brackets may need to be trimmed (e.g.:

to fi t under a fl ashing). Place the Finish

Collar around the support and fasten it to

the ceiling using the screws provided.

3) Use appropriate roof fl ashing. Place the

fl ashing under the upper shingles and on top

of the lower shingles approximately half of

the fl ashing should be under the shingles.

4) Assemble the desired lengths of Black

Pipe and Elbows necessary to reach from

the appliance adapter up through the sup-

port box and fl ashing to proper height as

per Dia. 12, local codes or in the "Venting

Arrangment" section. Ensure that all pipe

and elbow connections are in their fully twist

lock position.

5) Ensure vent is vertical and secure fl ashing to

the roof with roofi ng nails. Slide the storm

collar over the pipe section and seal with a

mastic.

6) Twist lock the vent cap on to the last sec-

tion.

Support Extensions - Round

(RDSE)

or Square (SQSE)

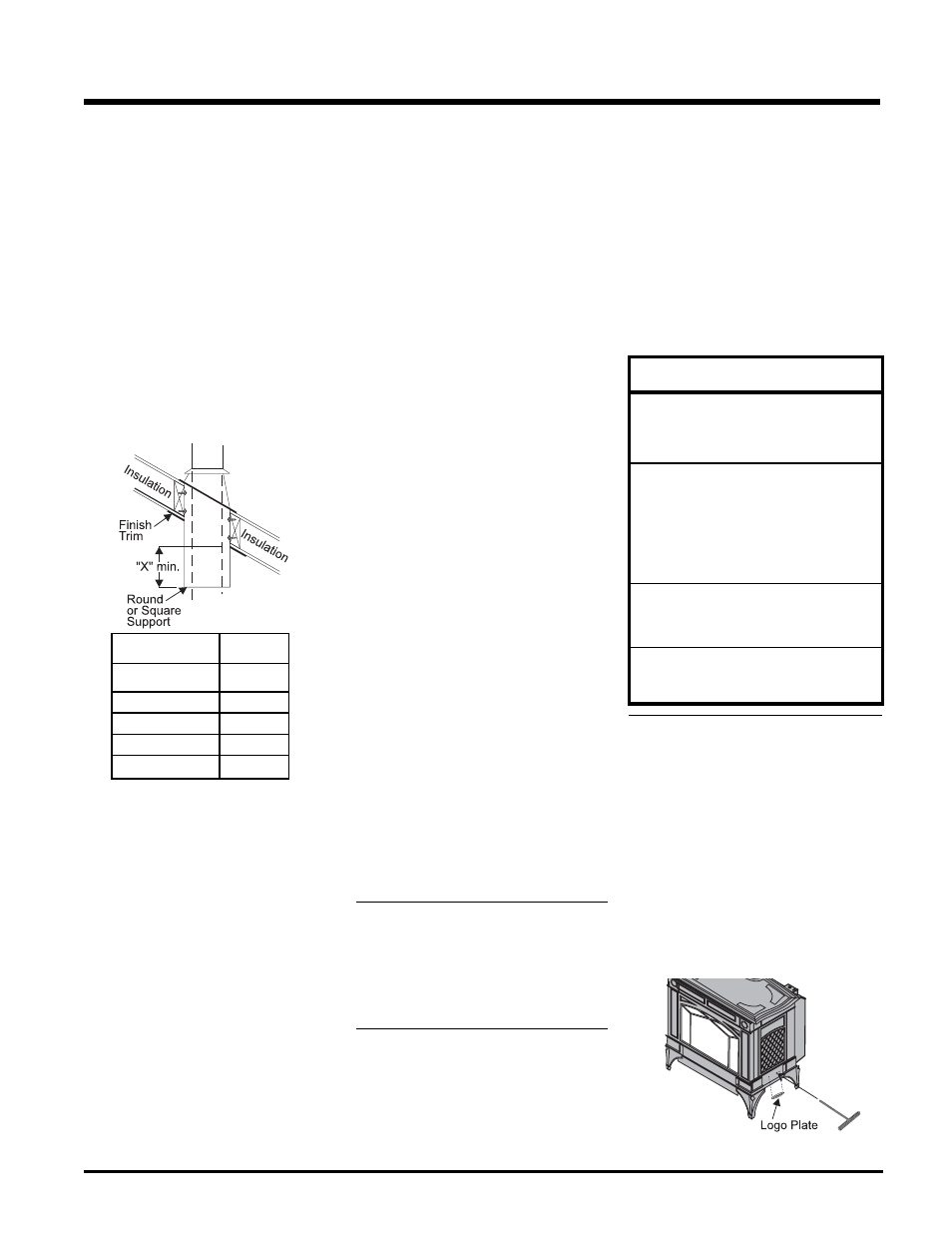

Steep pitched cathedral ceilings may require

the use of a support extension. This piece fi ts

down inside the support and can be adjusted to

increase the support's length by up to 22". The

extension is attached to the support using the

eight metal screws provided. Be sure there is

at least a 2 inch overlap where the extension

joins the support.

HIGH ELEVATION

This unit is approved in Canada for altitude to

4500 ft. (CAN/CGA-2.17-M91). For Natural

Gas installations above 4500 ft. follow current

CAN/CGA-B149.1.

GAS CONNECTION

The gas connection is a 3/8" NPT 90

o

elbow.

The gas line can be rigid pipe or to make in-

stallation easier, use a listed fl exible connector

and/or copper tubing if allowed by local codes.

7) Ensure vent is vertical and secure the base

of the fl ashing to the roof with roofi ng rails,

slide storm collar over the pipe section and

seal with a mastic.

8) Install the vertical termination cap by twist

locking it.

Notes:

a) For multistorey vertical installations, a

Ceiling Fire stop (Part # 963) is required

at the second fl oor, and any subsequent

fl oor. Diagram 12. The opening should

be framed to 10 " x 10" inside dimen-

sions, in the same manner as shown in

diagram 9.

b) Any occupied areas above the fi rst fl oor,

including closets and storage spaces,

through which the vertical vent passes,

must be enclosed.

CATHEDRAL CEILINGS

Round Support (RDS) &

Square Support (SQS)

If your home has a cathedral ceiling (no attic

space between the ceiling and the roof), install

the chimney and support as follows.

1) Situate the chimney in a convenient loca-

tion as near as possible to the appliance

outlet. Cut and frame a hole in the roof for

the support. The sides of this hole must be

vertical with 1 1/4" clearance.

2) Place the support in the opening. Lower it

to the correct height as determined by the

table and diagram below.

Using a level, make sure the support is

vertical. If the support extends above the

roof, cut it fl ush with the top of the roof.

Nail the support to the frame opening using

(8) 3" spiral nails or #8 x 1-1/2" screws.

Slope

"X"

0/12 -

2/12

4"

2/12 -

7/12

5-1/2"

7/12 -

12/12

6-3/4"

12/12 - 24/12

7-1/2"

24/12+

12-1/2"

Since some municipalities have additional local

codes it is always best to consult with your local

authorities and the CAN/CGA B149 installation

codes.

For USA installations follow local codes and/or

the current National Fuel Gas Code, ANSI

Z223.1.

When using copper or fl ex connectors use only

approved fi ttings. Always provide a union so that

gas lines can be easily disconnected for burner

and/or valve servicing. Flare nuts for copper lines

and fl ex connectors are usually considered to

meet this requirement.

INSTALLATION