Intek 200 User Manual

Page 23

-21-

I : \ O F F I C E \ W P M A N U A L \ M a n 2 0 0 r v b . w p d

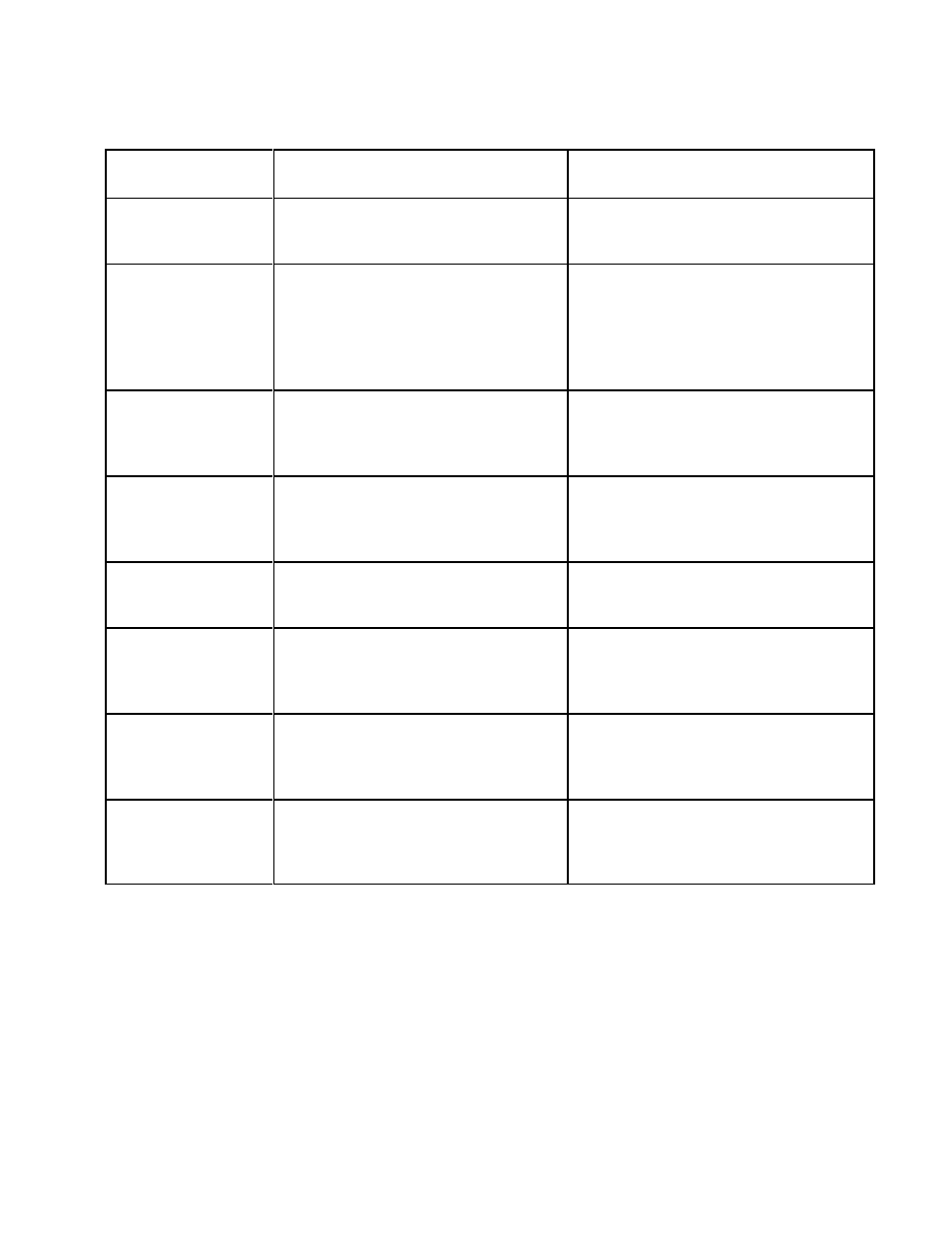

TABLE III. Trouble Shooting Guide - Instrument diagnosed problems

OBSERVATION

PROBABLE CAUSE

ACTION

'GENERAL FAULT'

'MODE 0'

1. Cable cut or not connected at all

1. Check cable for contact and

continuity

'GENERAL FAULT'

'MODE 1'

1. Improper cable hookup

2. Failed A/D circuit. Short between

sensor terminals O and BLU of

JP2.

3. Damaged flow sensor

1. Verify cable hookup is correct

2. Check cable connections for proper

contacts or moisture & corrosion

3. * Contact factory

'GENERAL FAULT'

'MODE 2'

1. Cable contact corroded

2. Damaged flow sensor

1. Check both ends of cable for

moisture or corrosion

2. * Contact factory

'GENERAL FAULT'

'MODE 3'

1. Shorted cable connection

2. Damaged flow sensor

1. Check for short in cable due to

moisture or corrosion

2. * Contact factory

'GENERAL FAULT'

'MODE 4'

1. Blown heater fuse at F1

2. Damaged flow sensor

1. Check wiring and replace fuse

2. * Contact factory

'GENERAL FAULT'

'MODE 5'

1. Sensor’s heater connection is open

between terminal O and R of JP2

2. Damaged flow sensor

1. Check sensor heater for an open

connection

2. * Contact factory

'GENERAL FAULT'

'MODE 6'

1. Temperature is above the specified

maximum (see instrument tag)

2. Possible sensor damage

1. Record temperature and remove

sensor from flow stream

2. * Contact factory

Oscillating status

output and/or

flashing display.

1. Software malfunction or corrupt

calibration parameters.

2. Failed electronic component.

1. Contact factory regarding restoring

factory calibration parameters.

2. * Contact factory

* Complete Table IV before contacting factory.