276k-asy: 402-276k installation details – Great Plains Swath Command Section Control User Manual

Page 45

Great Plains Manufacturing, Inc.

Appendix A - Reference Information

41

2012-08-23

402-382M

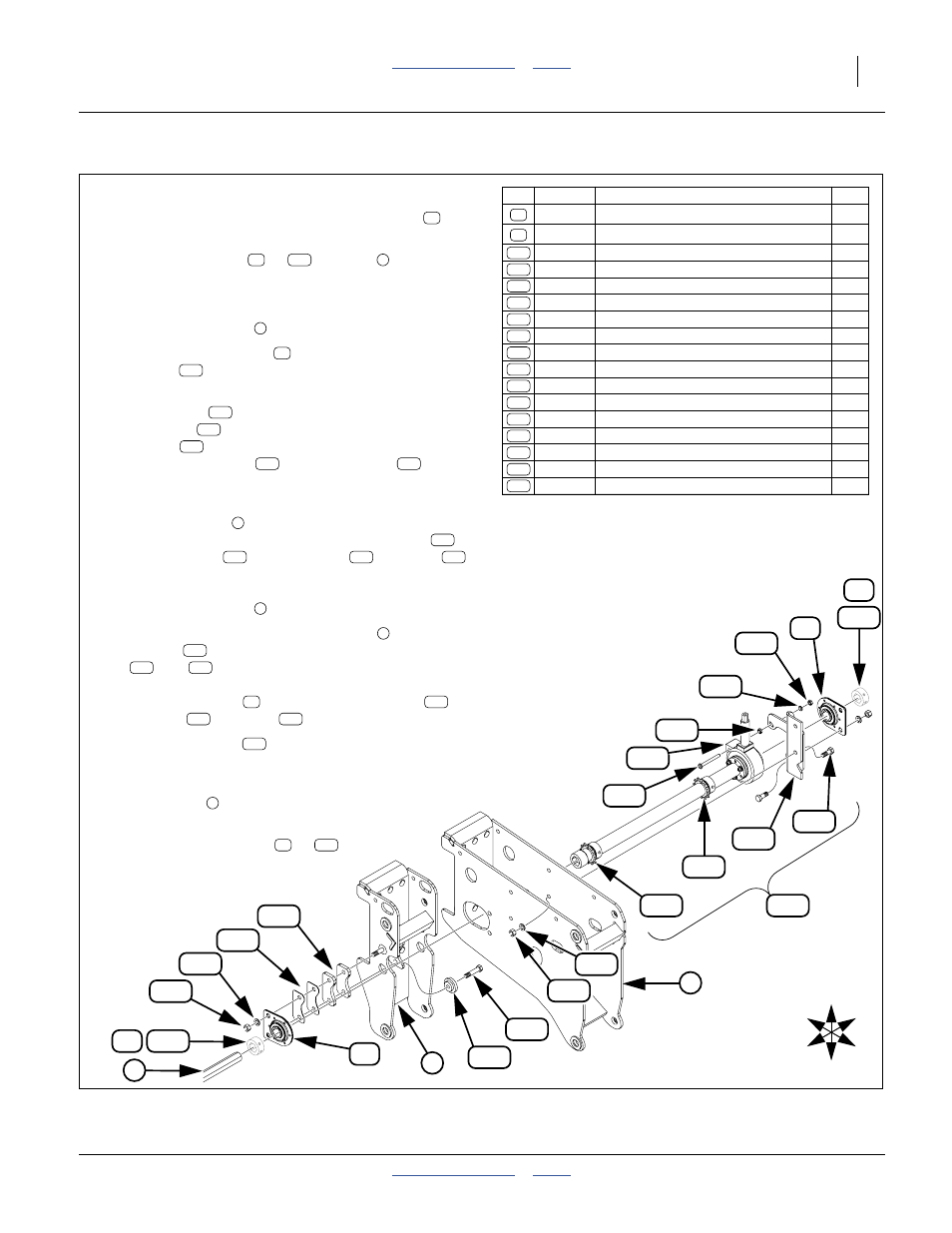

402-276K-ASY: 402-276K Installation Details

101

c/o PART NO

DESCRIPTION

Page

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

822-239C PEER 7/8 HEX BRG AND MNT (TYP ROW)

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

402-276K TRU-COUNT 15 IN LH ASM

402-527D SPACER PLATE FRT BEARING

402-532D OFFSET BRG BRACKET LH

402-539D STEP BUSHING FOR OPENER BRG

402-541D SPACER SHIM FRT BRG TRU COUNT

802-017C HHCS 3/8-16X1 GR5

802-023C HHCS 3/8-16X1 3/4 GR5

802-097C HHCS 1/4-20X2 1/2 GR5

803-006C NUT HEX 1/4-20 PLT

803-014C NUT HEX 3/8-16 PLT

804-006C WASHER LOCK SPRING 1/4 PLT

804-013C WASHER LOCK SPRING 3/8 PLT

808-415C SPKT 41B12 SPCL

823-328C TRU-COUNT LH AIR CLUTCH

15

26

101

111

191

194

199

201

224

226

228

237

238

242

245

257

261

U

D

L

R

B

F

Figure 38

402-275K-ASY Two-Row 15 Inch (LH Clutch) Installation Details

32207

26

15

Steps:

This installation relocates both original bearings

,

presumed to be removed.

1.

Add a lock collar (

or

) to shaft

before

installing the clutch only if specified on the clutch

layout drawing for your planter and kit. Not all rows

have collars. Secure set screws after all clutches are

installed and shaft

is in its final position.

2.

Mount saved bearing

outside (RH) offset

bracket

, using saved bolts, lock washers and

nuts.

3.

If the clutch

is not attached to the offset bracket,

insert bolt

through the anti-rotation foot. Add a

jam nut

. Insert the bolt end through the bracket.

Add a lock washer

and another nut

. Tighten

nuts only to Grade 2 torque.

4.

Insert the clutch assembly through the right side of

the long mount

. Loop meter chains for both rows

(not shown) over clutch tube. Secure bracket

with

two sets bolts

, lock washers

and nuts

.

Do not adjust chain slack until all clutches are

installed and shaft

is in its final position.

5.

Re-install bearing outside left mount

, using a step

bushing

and a combination of spacer plates

(

and

) as needed to allow clutch assembly

0.060 to 0.120 inches (1.5-3 mm) travel between

the two bearings

. Secure with new bolts

, lock

washers

and nuts

.

6.

Adjust sprockets

on tube for

0.75 inch (19 mm) distance from inside left wall of

opener mount to center-line of sprocket teeth.

7.

Insert shaft

through both bearings and

the clutch assembly.

8.

Add a RH lock collar (

or

)

if specified.

26

15

101

1

1

26

194

261

228

237

242

237

2

188

224

245

238

1

3

199

191

201

26

226

245

238

257

1

15

101

191

1

2

26

194

261

224

111

242

228

237

3

238

245

199

201

257

237

257

224

245

238

101

15