Bryant Air Coold Split System 575B User Manual

Page 15

—

15

—

PRE-START-UP

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

review Start-Up Checklist at the back of this book. The

checklist assures proper start-up of the system and provides

a record of unit condition, application requirements, system

information, and operation at initial start-up.

I. PRELIMINARY CHECKS

1. Check all air handler and other equipment auxiliary

components. Consult manufacturer’s instructions

regarding any other equipment attached to unit. If

unit has field-installed accessories, be sure all are

properly installed and correctly wired. If used, air-

flow switch must be properly installed. See Fig. 14 for

typical field wiring.

2. Backseat (open) compressor suction and discharge

valves. Now close valves one turn to allow refrigerant

pressure to reach test gages.

3. Open liquid line service valve.

4. Check tightness of all electrical connections.

5. 541A180 only — compressor oil level should be visible

in sight glass. Adjust the oil level as required. No oil

should be removed unless the crankcase heater has

been energized for at least 24 hours. See Start-Up

section, Preliminary Oil Charge.

NOTE: 575B, 575C units do not have a compressor oil

level sight glass. These units are factory charged with

the required amount of oil. If required, use the follow-

ing oil for replacement: For 575B and 541A units use

Zerol 150, part number P903-2001. For 575C units

use R015, part number P903-0101.

6. Leak test the entire refrigerant system using soap

bubbles and/or an electronic leak detector. Evacuate

and dehydrate entire refrigerant system.

7. Electrical power source must agree with nameplate

rating.

8. Turn on crankcase heater for 24 hours before starting

the unit to be sure all refrigerant is out of the oil. To

energize crankcase heater, perform the following

steps:

a. Set the space thermostat system switch to OFF, or

adjust the temperature so there is no demand for

cooling.

b. Close the field disconnect.

c. Leave the compressor circuit breaker off. The

crankcase heater is now energized.

9. As shipped, compressor is held down by 4 bolts. After

unit is installed, loosen each bolt and locknut until

flat washer or snubber can be moved with finger pres-

sure. Be sure compressor floats freely on the mount-

ing springs (541A units only). See Fig. 15A and 15B

for compressor mounting.

II. PRELIMINARY

CHARGE

Before starting the unit, charge liquid refrigerant into the

high side of the system through the liquid service valve. The

amount of refrigerant added must be at least 80% of the

operating charge listed in the Physical Data table (Table 1,

page 6). Allow high and low side pressures to equalize before

starting compressor. If pressures do not equalize readily,

charge vapor on low side of system to assure charge in the

evaporator. Refer to GTAC II, Module 5, Charging, Recovery,

Recycling, and Reclamation for liquid charging procedures.

III. LIQUID LINE SOLENOID

To minimize refrigerant migration to the compressor during

the heat pump OFF cycle, the 575B,C unit must have a

bi-flow liquid line solenoid valve (field supplied). The valve

opens when the compressor is energized, and closes when

the compressor is deenergized. This reduces compressor

flooded starts, thus significantly increasing compressor life.

IV. ACCUMULATOR

The unit accumulator controls the rate of liquid refrigerant

to the compressor during heat pump operation.

The 541A accumulator features a unique method for

returning oil to the compressor. The oil return mechanism is

external to the accumulator. The mixture of oil and refriger-

ant is metered to the compressor by a brass orifice which is

removable and cleanable. The oil return mechanism also

contains a solenoid valve that opens when the compressor is

ON and closes when the compressor is OFF. This keeps the

liquid refrigerant stored in the accumulator from draining to

the compressor during the heat pump OFF cycle, which

further protects the compressor against flooded starts.

CAUTION: Do not attempt to start the heat pump

system, even momentarily, until the following steps

have been completed. Compressor damage may result.

CAUTION:

Prior to starting compressor, a preliminary

charge of refrigerant must be added to avoid possible

compressor damage.

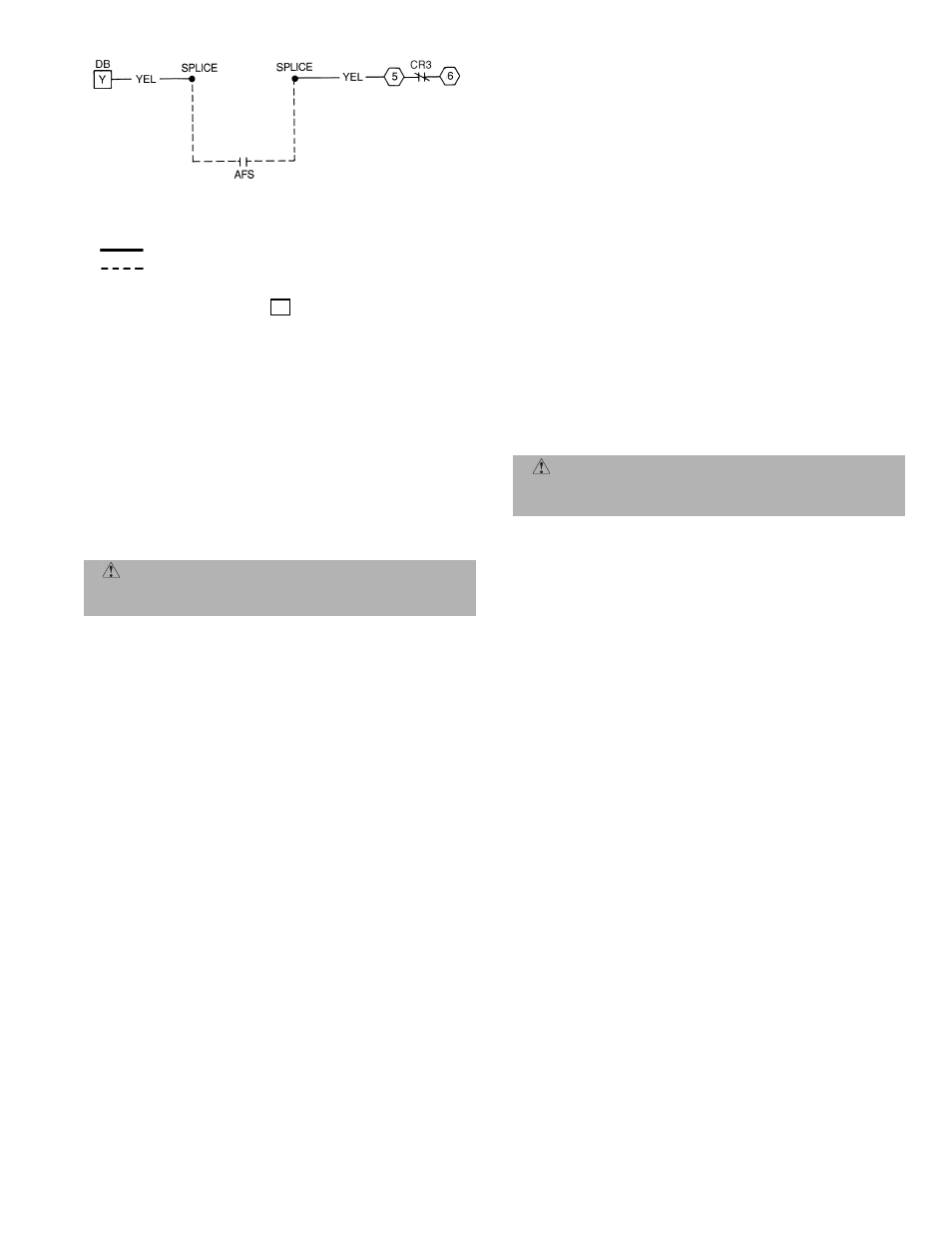

LEGEND

NOTES:

1. Locate YEL wire between

on DB and terminal 5 of CR3

and cut.

2. Splice airflow switch (AFS) (field supplied) contact wires (field

provided) to two ends of cut YEL wire as depicted.

Fig. 14 — Typical Field Wiring for Airflow Switch —

541A180/524A-H

AFS — Airflow Switch (Sail Switch)

CR

— Control Relay

DB

— Defrost Board

Factory Wiring

Field Control Wiring

Y