Assembly – Wood’s Powr-Grip HFV6000 User Manual

Page 8

Rev 12.0/12-13

6

HFH/V6000: #35000:

ASSEMBLY

1) Open the shipping container and remove all materials for restraining or protecting the vacuum

lifter during shipping. Save the container for use whenever the lifter is transported.

2) Suspend the lifter from a crane as follows: Select hoisting equipment (crane and hoist, when

applicable) rated to carry the maximum load weight plus the lifter weight (see

SPECIFICATIONS: Load Capacity and Lifter Weight).

Note: Any application of the lifter must conform to all statutory or regulatory standards that

relate to the hoisting equipment when used in its geographical location (eg, relevant OSHA

standards in the USA).

WARNING: Hoisting equipment hook must be fitted with restraining latch to

prevent lift bail from slipping off under any circumstances.

Tilt the lifter upward enough for the lift bar to move freely, without interference from the

shipping container. Swing the lift bar to the center position of the 180° rotation range, where

it latches in position automatically.

Disengage the tilt latch (see OPERATION: T

O

T

ILT THE

L

OAD

) and raise the lift bar to a vertical

orientation. Then attach the hoisting equipment hook to the lift bail.

Note: Some hoisting equipment hooks could interfere with an upright load that extends

beyond the lifter's pad frame. If the load would contact the hook during lifter operation, the

operator must prevent this by attaching a sling (or other rigging that does not interfere with

the load) between the hook and the lift bail.

WARNING: Any sling used must be rated to carry maximum load weight plus

lifter weight.

Use the hoisting equipment to raise the lifter out of

the shipping container.

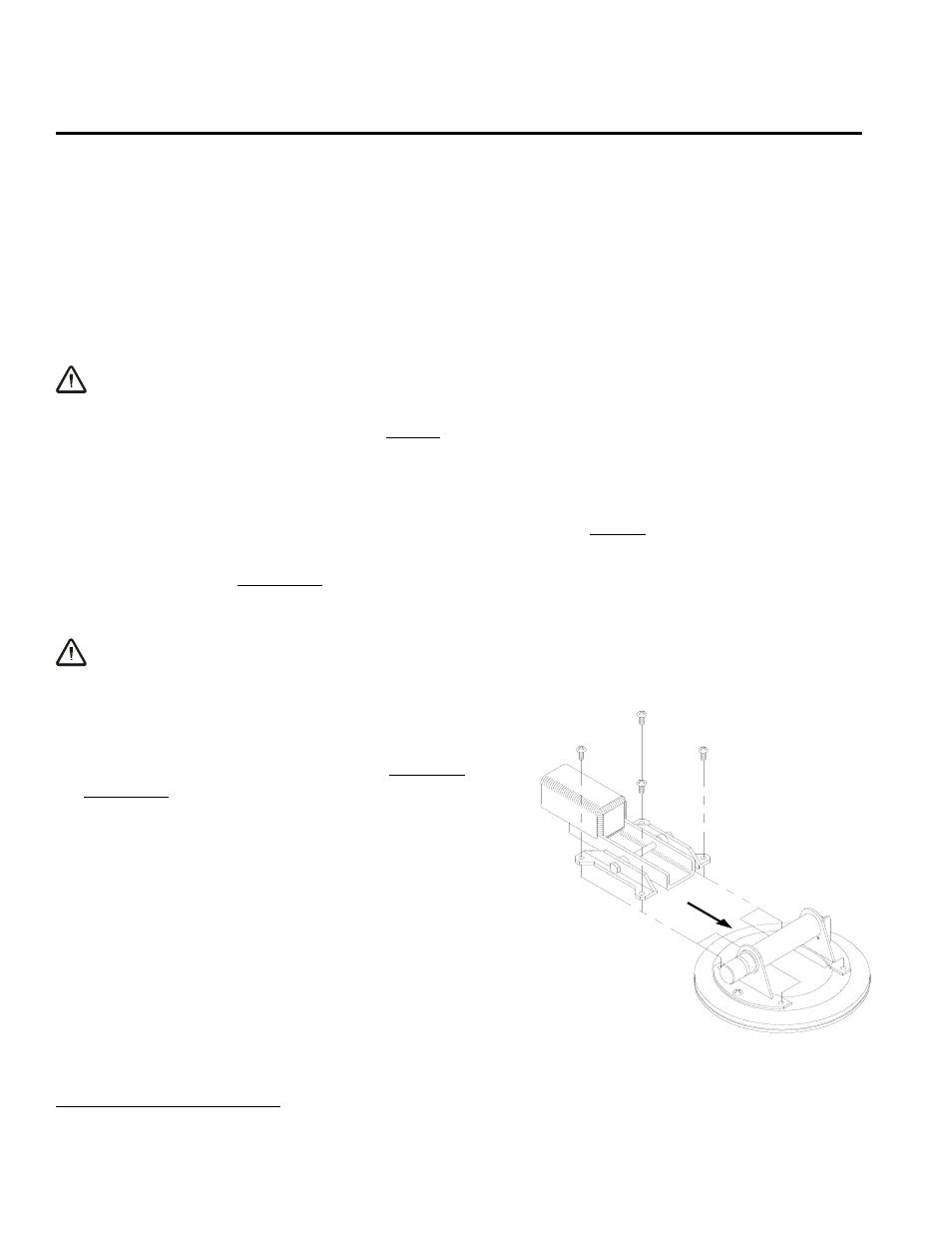

3) Attach each Powr-Grip model N5450 hand cup to the

pad frame, as follows (see illustration):

3

Remove the four screws from the corners of the

hand cup’s handle base.

Slide the hand cup over the mount on the pad

frame.

Insert the 1/4-20 x 5/8" screws (provided) through

the mount and into the hand cup; then tighten the

screws securely. Now the lifter is operational.

4) Perform Operational and Load Tests for the lifter as

directed in MAINTENANCE: T

ESTING

S

CHEDULE

.

3

Other hand cups may reduce load capacity or be incompatible.