Crosscut ends rip hinge to final width – INCRA HingeCrafter User Manual

Page 7

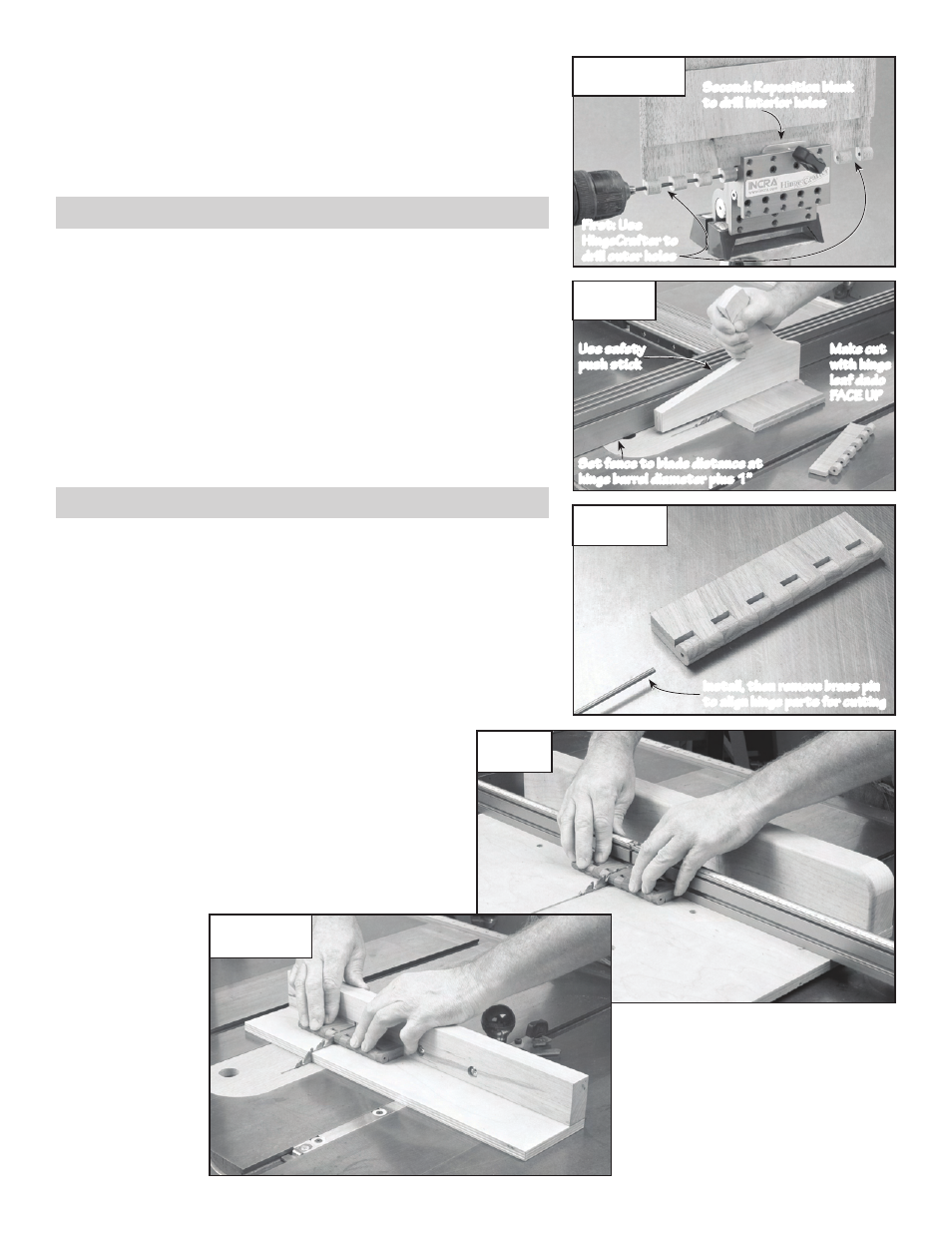

Before removing the hinges from each end of the blank, make the

safety push stick described in the full-scale plan included with this

manual. Use

3

/

4

” plywood and cut out the push stick with a band saw

or scroll saw. Sand the push stick to remove any sharp edges around

the handle.

Set the fence to blade distance at your table saw equal to the hinge

barrel diameter plus 1”. (Example: For the

1

/

2

” barrel diameter set the

fence to 1

1

/

2

”.) With the rounded end of the blank against the fence

and the hinge leaf dado face up, use the push stick to move the blank

through the cut,

Fig. 22. Repeat for the opposite end.

CAUTION: Never make the above-described cut with the hinge

leaf dados face down.

Before cutting your finished hinge to final width, carefully assemble the

two halves of the hinge blank and install the brass hinge pin. If you

experience any difficulty installing the hinge pin, you can run the drill

bit back through the hinge to clean out any chips that may be blocking

the holes. After installing the brass pin, close the hinge and carefully

remove the hinge pin. This aligns the hinge parts for cutting,

Fig. 23.

CAUTION: Never make final sizing cuts with the brass pivot pin

installed.

The final sizing of your finished hinge must be accomplished by

making the cuts using a crosscut box or miter gauge

carrier as shown in

Figs. 24 and 25. Although these cuts

appear to be crosscuts, they are in fact short grain rip

cuts and require backing support for safe cutting. Each

of the methods of cutting shown provides necessary

backing support for the hinge blank on both sides of the

cut. Dimensioned plans for the miter gauge carrier can

be found on page 8. Hold the squared end of the hinge

assembly firmly against your crosscut box or miter gauge

carrier back fence

as you make the

cut. Determine

the final cut width

depending on the

requirements for

your application. In

general, the smallest

hinge should have

five knuckles for

maximum strength

(three on one side

and two on the

other).

INCRA HingeCrafter

7

FIG. 21

Drill extra long hinges

FIG. 22

Crosscut ends

FIG. 24

Crosscut box

FIG. 25

Miter gauge carrier

NOTE: Owner’s manual photos

show the blade guard removed

for instructional clarity only. You

should use your blade guard and

other safety equipment whenever

appropriate to protect yourself.

Refer to your equipment manuals

for proper safety instructions.

CROSSCUT ENDS

RIP HINGE TO FINAL WIDTH

For extra long hinges, first drill one end of the hinge blank, then

unclamp, reposition and drill the opposite end of the hinge blank.

Finally, unclamp and reposition with the center of the hinge in the

HingeCrafter and drill through the existing outer holes to reach the

center. For the longest hinges it will be necessary to complete the

holes in the center by drilling from both ends and in a few cases a

third repositioning is required,

Fig. 21.

First: Use

HingeCrafter to

drill outer holes

Second: Reposition blank

to drill interior holes

Use safety

push stick

Set fence to blade distance at

hinge barrel diameter plus 1”

Make cut

with hinge

leaf dado

FACE UP

Install, then remove brass pin

to align hinge parts for cutting

FIG. 23

Align hinge parts