Drill hinge knuckles, Cut the hinge knuckles – INCRA HingeCrafter User Manual

Page 6

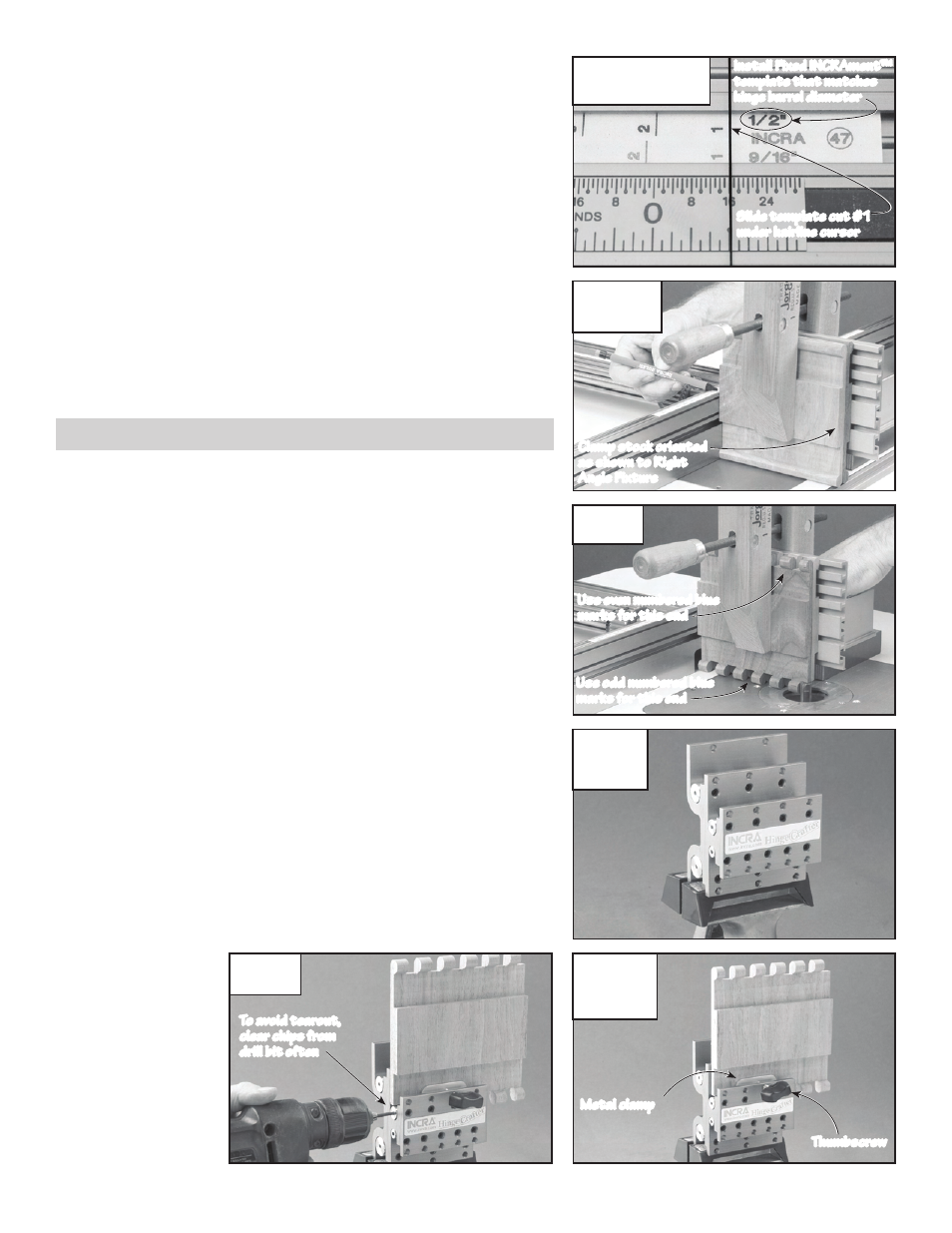

Install the Fixed INCRAment™ template from your INCRA Master

Template Library that corresponds to the hinge barrel diameter you

have selected. For example, if you selected the

1

/

2

” hinge barrel

diameter, use the Fixed INCRAment™ template with

1

/

2

” spacing

(Template #47). Slide the template to position cut #1 on the template

directly under the hairline cursor,

Fig. 15.

Cut The Hinge Knuckles

Clamp the two blanks back to back to your INCRA Right Angle Fixture

as shown in

Fig.16 and mark the “fence” edges of the pieces. Turn

the router on and take a couple of passes to sneak up to cut #2 on the

template. Proceed by making cuts at each of the even numbered blue

cut marks on the template. Turn off the router.

Unclamp the two blanks and flip to cut the opposite ends. Before

clamping, make sure that the marked “fence” edges are against the

fence. Now proceed by making cuts at each of the odd numbered

blue cut marks on the template beginning with cut #3,

Fig. 17.

Your HingeCrafter is equipped with four different bushing sizes, one

for each barrel diameter (

3

/

8

”,

1

/

2

”,

5

/

8

”, and

3

/

4

”). The spacing set

for the bushings within the HingeCrafter makes matching the barrel

diameter to the correct bushings easy. Just find the bushing section

that allows your hinge knuckles to slide in between the bushings.

After identifying the correct section, clamp the HingeCrafter in a

bench vise as shown in

Fig. 18. If you don’t have a bench vise, just

clamp the HingeCrafter to the corner of your workbench to allow

drilling from both sides of the fixture.

Slide your hinge blank into the drill guide as shown in

Fig. 19 and use

the thumbscrew in one of the threaded holes to clamp the hinge blank

in place. To protect the hinge, slide the provided metal clamp pad

between the hinge and the thumbscrew before tightening. Make sure

that the hinge blank is pressed firmly and squarely into the bushings

before tightening the clamping thumbscrew.

Install the provided #30 (.128”) drill bit in a hand drill and drill the

hinge blank,

Fig. 20. Clear the chips from the drill bit often. If

the chips are not cleared from time to time, the drill bit will load and

create tearout on the backside of the knuckle, or worse, crack the

hinge. Remember, a clean drill bit drills while a loaded drill bit just

pushes hard. For hole position accuracy, never drill more than one

knuckle beyond the last bushing of the drill guide. To complete the

hole, unclamp and reposition the hinge blank, then drill through the

opposite end of the drill

guide.

IMPORTANT:

Whenever

repositioning the

hinge blank, always

blow sawdust and

wood chips out of

the drill guide before

reinserting the hinge

blank.

FIG. 15

Install Fixed INCRAment™

template

FIG. 16

Mark fence edge

on blanks

FIG. 17

Cut knuckles

FIG. 18

Clamp

HingeCrafter

in vise

FIG. 19

Clamp hinge

blank in

HingeCrafter

FIG. 20

Drill knuckles

6

INCRA Woodworking Tools & Precision Rules

DRILL HINGE KNUCKLES

Install Fixed INCRAment™

template that matches

hinge barrel diameter

Slide template cut #1

under hairline cursor

Clamp stock oriented

as shown to Right

Angle Fixture

Use odd numbered blue

marks for this end

Use even numbered blue

marks for this end

Metal clamp

Thumbscrew

To avoid tearout,

clear chips from

drill bit often