Disclaimer – H&H Specialties 600 Series Track Installation Instructions User Manual

Page 3

H & H Specialties Inc.

600 Series Installation

South El Monte, CA 91733

February 20, 2007

Page 3 of 3

3. Double spindles (618) are mounted on the inside of the curve

on the double end pulley track only.

4. Single spindles (619) are mounted on the inside of the curve

on the single end pulley track only.

5. Outside idlers (620) are mounted on the outside of the curve

on the single end pulley track only.

6. Spindles and idlers are also suggested on straight track

sections of 6'-0" and longer.

7. Since idler number, spacing and placement are unique for

each job, please consult the factory for further information.

Splices

1. In order to have a smooth operating track it is important that

the track splices are installed properly and carefully. Make sure

that the ends of the track are smooth and no ragged edges are

protruding.

2. Whenever possible, splices should be located on straight

sections of track. If track must be spliced on a curve it might be

necessary to bend the splice to match the radius of the bend.

3. A drill fixture (607FX) is available from the factory to

facilitate field drilling of splices for the 600 Series track.

Pivot Devices

1. Pivot devices allow for curtains to be positioned at different

angles relative to the track. Both the 60 and 60X are free-

wheeling devices. The 60BK brake kit is available as an

optional accessory for holding the device in a fixed position.

The "X" suffix stands for a special indexing device that allows

the curtain to be placed in preset positions at 22½

o

increments.

2. The pivot device is designed for either 1-3/8"O.D. tubing or

1" Sch. 40 pipe. Maximum recommended batten length is 6'-0".

Make sure that the batten is the proper length for the

application.

3. Place the "C" clamps in each end of the curtain batten. They

are provided so that a cord may be tied between the two to aid in

turning the device. The cord should be long enough so that

adjustment may be done with the curtain at its proper trim.

4. CAUTION! Do not attempt to adjust the curtain by

means of pulling on the fabric. Damage to the curtain and

associated hardware may result.

5. The recommended total load on the device

must not exceed

75 pounds.

Miscellaneous

1. Rubber bumpers are supplied (2 for each carrier) and should

be placed on the "ears" on the side of the carrier that face the

end pulleys.

2. A 4'-0" minimum is suggested for ease of operation and for

optimum life. Consult the factory for a radius less than 4'-0".

3. When using the curved 600 Series track with light-weight

fabrics, the carriers may bind as they go around the curve.

Adding weight to the bottom of the curtain and connecting the

carriers together with chain will help alleviate the problem.

4. NOTE: Rigged 600 Series tracks (manual and machine

operated) are not designed for reverse or "S" curve operation.

The design and operation of the spindle and idler assemblies

does not allow this feature. If design of track layout requires a

reverse bend, the 500 Series heavy duty curved track is a

suitable choice. 600 Series tracks may be reverse curved for

walk-along applications only.

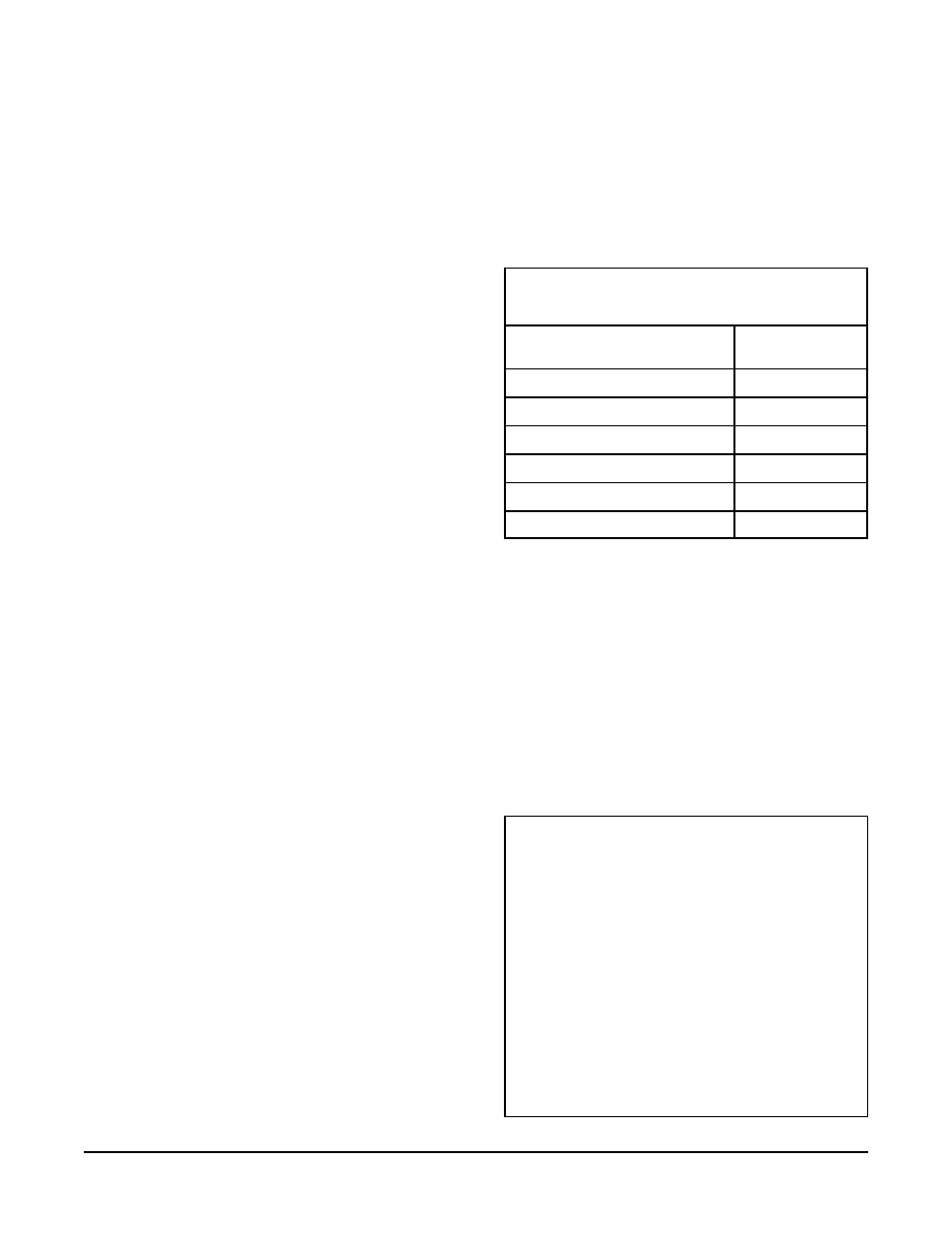

RECOMMENDED TRACK SUPPORT SPACING

Using 606 Clamp Hanger or

611 Ceiling Hanger (in feet)

Curtain Weight

Per Carrier (pounds)

610A

2

5

3

5

4

5

5

4.5

6

4

7

4

For additional information, please refer to Catalog Fourteen, pages 62-

63. For tracks 10 feet or less in length it is recommended that the track

be supported at a minimum of three locations.

All recommendations stated are presented in good faith and based upon

generally accepted engineering principles. The user, however, is

cautioned that H & H Specialties Inc. cannot guarantee the accuracy of

the data presented in this table for every situation. It is the customer’s

responsibility to determine the suitability of H & H Specialties’ products

for any given application, taking into account the specific requirements,

the environment of use, and any possible peculiarities of the application.

for this application.

Direct ceiling attachment of tracks has not been evaluated as the support

structure, method of attachment, and attachment requirements may vary

widely from project to project. A qualified person should be consulted

DISCLAIMER

This product is designed for moving curtains or, in

some cases, scenery.

NONE OF THE ITEMS DESCRIBED HEREIN ARE

DESIGNED, INTENDED OR WARRANTED FOR

THE USE OF LIFTING OR TRANSPORTING

PEOPLE OR OTHER LIVING OBJECTS.

H & H Specialties Inc. makes no representation of the

suitability of any product for any application unless

specific design drawings are made by the factory and

the products are installed in precisely the manner

detailed by our design staff.