H&H Specialties 600 Series Track Installation Instructions User Manual

Page 2

H & H Specialties Inc.

600 Series Installation

South El Monte, CA 91733

February 20, 2007

Page 2 of 3

proper alignment of the track sections may not be possible.

5. Attach the double end pulley (603)to one end of the track.

From the other end insert single carriers (601, 616, or 628) and

the insert the master carrier (642, 647, or 649) into the track.

Finish by attaching the single end pulley (604A). NOTE: For

one-way operation a 604A single end pulley should always be

used.

6. If the track is being suspended from a counterweight system,

balance the system now. WARNING! After attaching track

to a counterweighted batten, make sure to balance the line

set and leave at a comfortable working level.

7. Start to reeve the hand line from the upper sheave of the

double end pulley. The rope goes over the sheave and through

the top sheave of the double spindles (618). In one-way track

installations, the double spindle is the only spindle used.

8. Reeve the hand line around the sheave of the single end

pulley and back to the master carrier. Terminate the hand line

into the rope clamp of the master carrier..

9. Reeve the other end of the hand line through the tension

spring floor block and up to the double end pulley. The spring

in the tension block should be extended when operating line is

first reeved. Reeve the handline over the sheave and terminate

at the master carrier. Remove slack in line and tighten cord

clamps. Release spring in floor block to place line under

tension. CAUTION! Exercise care when releasing tension in

spring to avoid injury. For counterweight batten mounted

tracks a 643 Sand Bag Tension Pulley should be used.

C. CEILING MOUNT INSTALLATION

Ceiling mounting the 600 Series is similar to the batten

mounting procedures. The following considerations should be

followed when ceiling mounting.

1. After laying out the track, use a plumb line or laser to locate

positions of the ceiling hangers relative to the track. Use

appropriate attachment methods for the individual job

conditions. Before installing ceiling hangers (611) make sure

that the ceiling is parallel to the floor. Shims may need to be

installed to compensate for irregularities.

2. After the hangers are installed, raise the track in sections and

attach to the ceiling hangers. In many cases, ceiling hangers can

be installed onto the track, then raised to the ceiling for

mounting of the hanger.

3. Rig track for either bi-parting or one-way travel.

D. SPECIAL INSTRUCTIONS

Spindles

1. For 600 Series tracks a radius of 4'-0" is recommended for

ease of operation. Tighter curves are possible and will result in

a system that requires additional effort to operate. For these

applications, consult the factory.

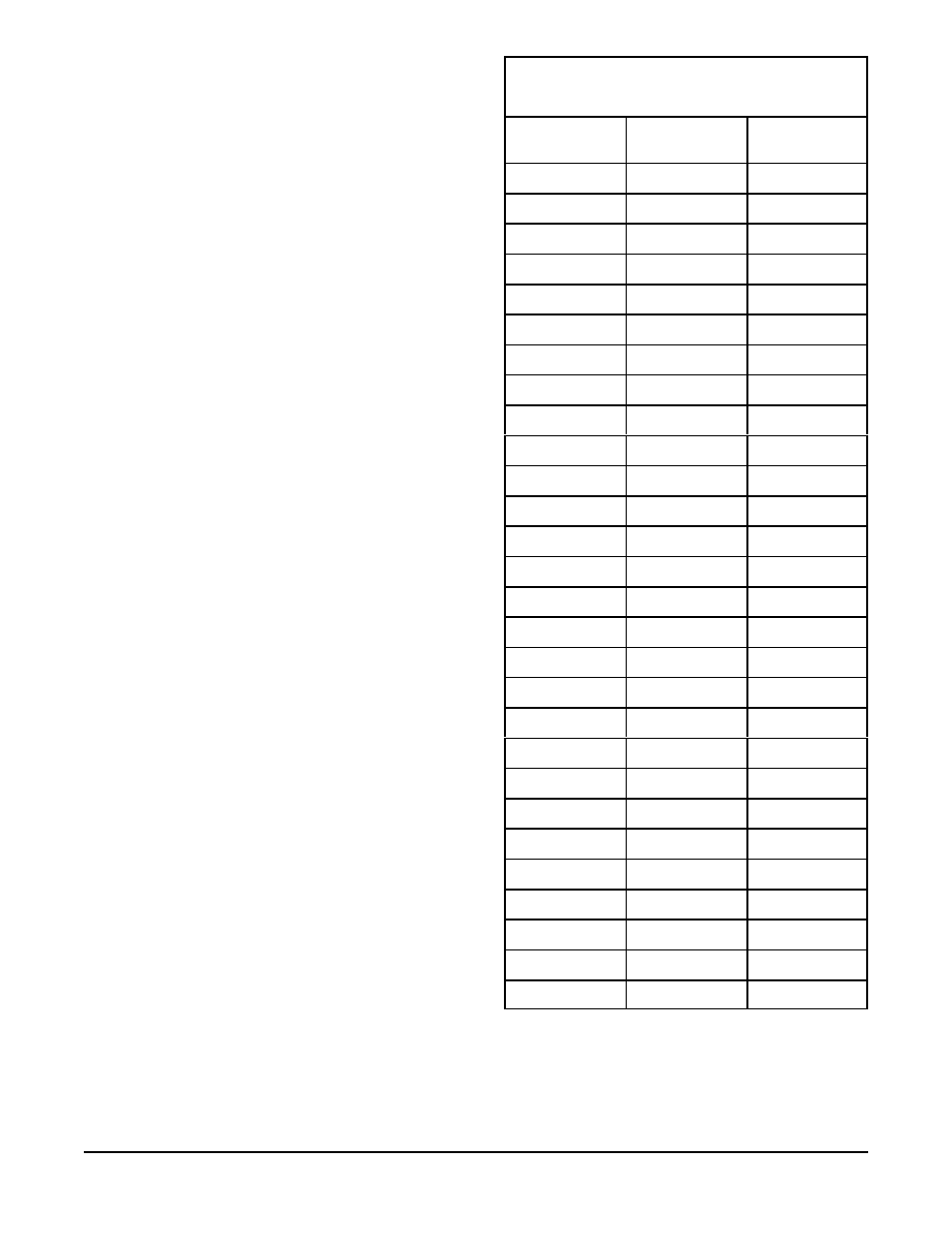

RECOMMENDED SPINDLE & IDLER SPACING FOR

CURVED 600 SERIES TRACKS

(based upon 90 degree curve)*

Radius

Spindle/Idler

Spacing

Suggested

Quantity

2'-0"

consult factory

consult factory

3'-0"

consult factory

consult factory

4'-0"

15"

6

5'-0"

16"

7

6'-0"

20"

7

7'-0"

22"

7

8'-0"

25"

7

10'-0"

32"

7

12'-0"

38"

7

14'-0"

38"

8

16'-0"

42"

8

18'-0"

48"

8

20'-0"

52"

8

22'-0"

60"

8

24'-0"

57"

9

26'-0"

61"

9

28'-0"

66"

9

30'-0"

71"

9

32'-0"

75"

9

36'-0"

75"

10

40'-0"

75"

11

44'-0"

75"

12

48'-0"

75"

12

52'-0"

75"

14

56'-0"

75"

15

60'-0"

76"

16

64'-0"

76"

17

68'-0"

76"

18

*For manual cord-operated tracks with a radius of 8'-0" or less,

the addition of one spindle and idler will help ease of operation

2. In locating spindles, place so that the cord is adequately

supported as it turns the corner. Use the following chart for

reference only. Due to site conditions, the numbers of spindles

required for ease of operation may vary.