Introduction, General, Operator qualifications – Gradall 534D-10 (9134-4052) Operation Manual User Manual

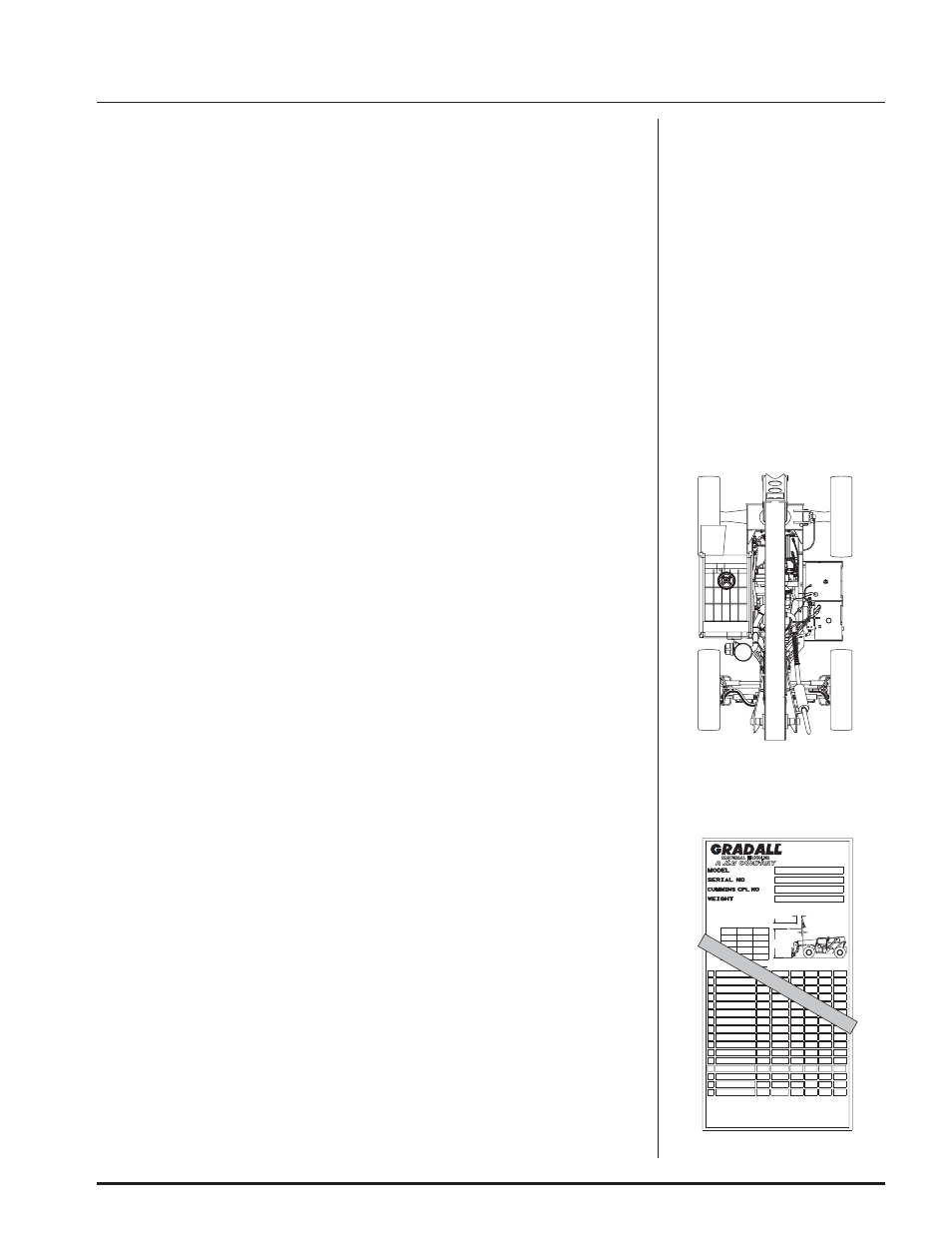

Page 7: Orientation, Related manuals & decals, Models covered, Serial number location, Rear front right left figure i-1 figure i-2, Sam ple o nly - use chart in cab

Form No. 20219

z

z

z

z

z

534D-9/534D-10 Owner/Operator Manual

General

This Manual provides important information regarding safe operating and

maintenance requirements for GRADALL Material Handlers.

If you have any questions regarding the material handler, contact your GRADALL

Material Handler Distributor.

Operator Qualifications

Operators of the material handler must be in good physical and mental condition,

have normal reflexes and reaction time, good vision and depth perception and

normal hearing. He must not be using medication which could impair abilities

nor be under the influence of alcohol or any other intoxicant during the work

shift.

The operator should possess a valid, applicable driver’s license and must have

completed a training course in the safe operation of this type of material handling

equipment.

In addition, the operator must read/view, understand and comply with

instructions contained in the following material furnished with the material

handler:

• This Owner/Operator Manual

• GRADALL Material Handler Safety Manual

• All warning and instructional decals and plates

• Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable

Employer, Industry and Governmental rules, standards and regulations.

Orientation

When used to describe the location of components in the material handler, the

directions “front’”, “rear”, “right” and “left” relate to the orientation of a person

sitting in the operator’s seat. (See Figure I-1)

Related Manuals & Decals

Separate publications are furnished with the material handler to provide

information concerning safety, replacement parts, maintenance procedures,

theory of operation and vendor components. Replacement manuals, decals

and instruction plates can be ordered from your GRADALL Material Handler

Distributor.

Models Covered

This Manual covers basic information for Gradall Material Handlers. Detailed

information for each particular machine is in the maintenance section in the

back of this manual. Be certain to refer to proper information for your unit and

the operational equipment furnished on your machine.

Serial Number Location

Specify Model Number and Serial Number when ordering parts and when

discussing specific applications and procedures with your Distributor. The model/

serial number plate is located inside the operator’s cab, right wall.

(See Figure I-2)

NOTE!

“Material handler” and handler are

used interchangeably throughout

this Manual.

Though no offense or

discrimination is intended, only

the masculine pronouns will be

used throughout the remainder of

this Manual.

NOTE!

REAR

FRONT

RIGHT

LEFT

Figure I-1

Figure I-2

INTRODUCTION

TRUSS BOOM

P/N 9045-5011

2

24,180

TRUSS BOOM W/WINCH

P/N 9045-5012

55

24,420

55

4

26,190

40

40

4

26,450

6' MAST W/48" CARR

P/N 9045-5035

6

25,380

6' MAST W/66" CARR

P/N 9045-5037

6

25,460

72" 100° SWING CARR

P/N 9045-5044

9

25,160

48" SLOPE PILER

P/N 9108-5058

9

24,630

66" SLOPE PILER

P/N 9130-5016

9

24,750

6' SW. MAST W/48" FORKS

P/N 9045-5047

6' SW. MAST W/60" FORKS

P/N 9045-5054

1.6

---

---

---

---

24

24

24

24

24

24

24

24

24

24

24

24

24

24

42

42

33

32

32

3.7

3.7

8.7

8.7

5

2

2

-.7

-1.6

-1.6

WORK PLATFORM

P/N 9055-5024

39

2.7

24,520

24,040

-.9

4.5

24,220

7

2.3

24

24

45

24,540

9

24

24

36

36

AS RELEASED FROM FACTORY THIS TRUCK MEETS THE DESIGN SPECIFICATIONS

A

B

C

D

ATTACHMENT

D

C

B

A

9

24,420

9134-3062 (REV. D)

(WITHOUT

ATTACHMENTS)

36

40

24

24

24

24

-.9

.5

9

8

23,570 LBS

36

24

24

9

-.9

-.9

24

24

3

45

---

---

3

45

---

---

2

24,320

---

---

III

FORKS RATED LESS THAN THE ATTACHMENT CAPACITY SHOWN ABOVE DECREASE CAPACITY

OF ATTACHMENT TO THAT OF FORKS. FORKS RATED MORE THAN ATTACHMENT CAPACITY DO

NOT INCREASE ATTACHMENT CAPACITY.

ESTABLISHED IN AMERICAN NATIONAL STANDARDS FOR POWERED INDUSTRIAL

TRUCKS PART ASME B56.6b-1998.

CAPACITY WITH STANDARD

48", 66", & 72" CARRIAGE

CAP#

1000

TRUCK &

ATTACHMENT

WEIGHT

SHIPPED

WITH

CAP#

X1000

*WEIGHTS ARE BASED ON USING 1 3/4 X 6 X 48" FORKS (APPROX. 356# PER PAIR)

**BUCKET DIMENSIONS (A & D) REFER TO BUCKET LIP HEIGHT.

***TRUSS BOOM, WINCH & QUICK HOOK DIMENSIONS (A & D) REFER TO HOOK CENTER.

****WEIGHT IS BASED ON SP'L SWING MAST FORKS (48": APPROX. 220# PER PAIR)

(60": APPROX. 490# PER PAIR)

*****PLATFORM DIMENSIONS (A & D) REFER TO CENTER OF FLOOR.

48" CARRIAGE

P/N 9045-5051

66" CARRIAGE

P/N 9045-5052

72" CARRIAGE

P/N 9055-5008

3/4 YD BUCKET

P/N 9045-5049

1 1/4 YD BUCKET

P/N 9055-5020

534D9-45

GRADALL IS A REGISTERED TRADEMARK

FOR HYDRAULIC EQUIPMENT

BUILT BY THE JLG COMPANY

1 JLG DRIVE, McCONNELLSBURG, PA.

U.S.A.

*

*

*

**

**

****

***

***

****

****

*

*

*

*

*

D

A

B

C

FT

FT

FT

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

FT

IN

IN

FT

FT

IN

IN

FT

FT

IN

IN

FT

FT

FT

FT

FT

FT

IN

IN

IN

IN

IN

IN

FT

FT

FT

FT

FT

SAM

PLE O

NLY - USE CHART IN CAB