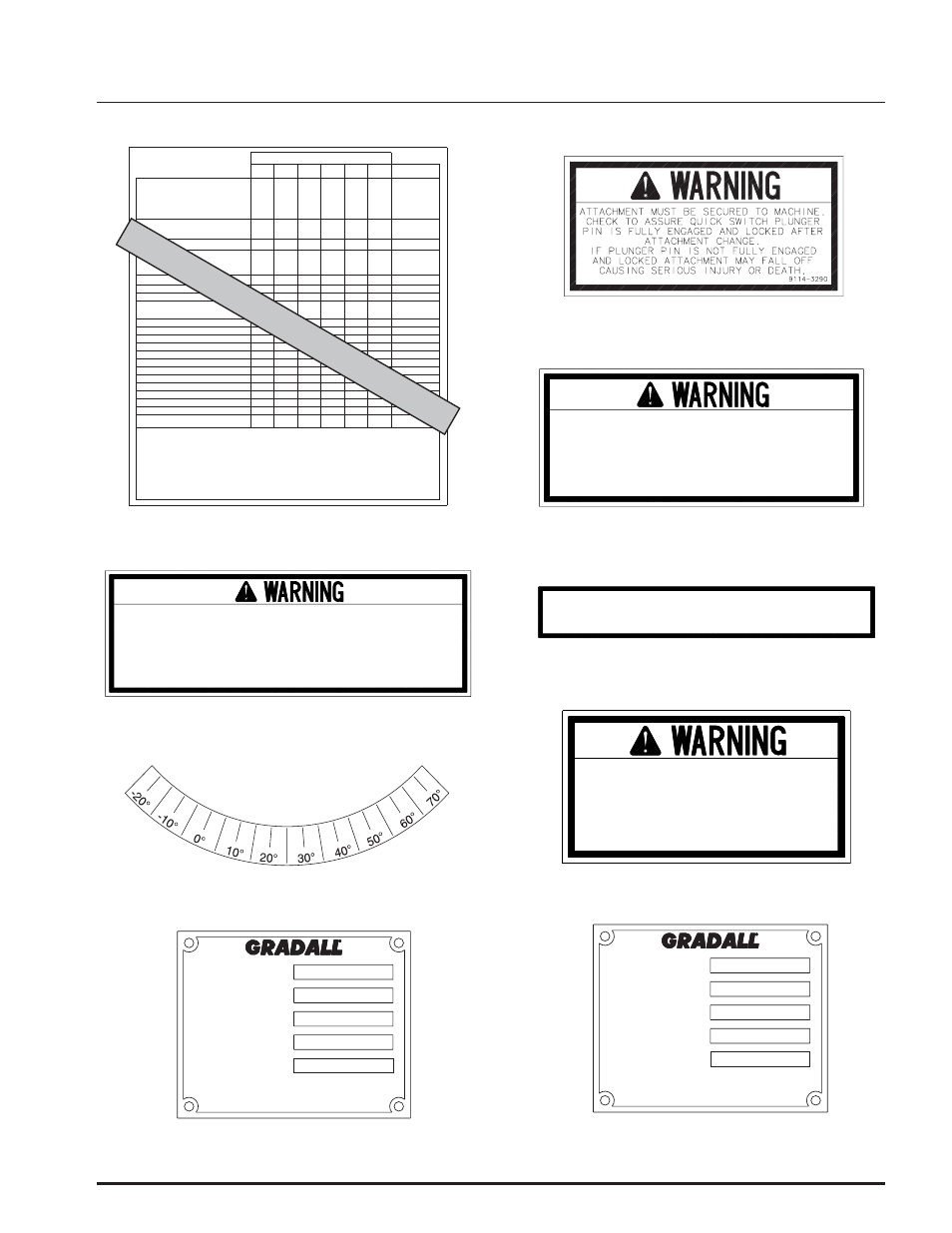

Attach lanyard here, Sample only - use chart in cab, Outside the cab – Gradall 534D-10 (9134-4052) Operation Manual User Manual

Page 15

Form No. 20219

z

z

z

z

z

534D-9/534D-10 Owner/Operator Manual

2.5

Located on left side of boom

P/N 9100-3031

OUTSIDE THE CAB

Located on mudguard

P/N 9134-3073

Located on boom head

P/N 9055-3026

Located on attachment

P/N 9015-3001

Located on mudguard

P/N 9055-3027

Located on Personnel Work Platform

P/N 9055-3032

Located on Personnel Work Platform

P/N 9055-3031

Located on Personnel Work Platform

P/N 9055-3033

Located on boom head

P/N 9114-3290

9055-3027 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK PLATFORM.

DO NOT DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

WHEN PERSONNEL ARE IN PLATFORM REMAIN SEATED IN CAB WITH PERSONNEL

IN DIRECT LINE OF SIGHT.

OPERATE CONTROLS LIGHTLY AND CAUTIOUSLY WHEN LIFTING PERSONNEL.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL BEFORE LIFTING PERSONNEL.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO

MADE IN U. S. A.

THE CAPACITY OF FORKLIFT, ATTACHMENT AND FORK

COMBINATION MAY BE LESS THAN THE CAPACITY SHOWN

ON ATTACHMENT - CONSULT FORKLIFT NAMEPLATE

AND ALSO INSURE FORKS ARE OF PROPER SIZE.

9015-3001

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

ATTACH LANYARD HERE

9055-3032

9055-3026 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED

PERSONNEL WORK PLATFORM.

ALL PERSONNEL IN PLATFORM MUST WEAR A FULL BODY HARNESS WITH

LANYARD ATTACHED TO A DESIGNATED ANCHORAGE POINT.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL

BEFORE OCCUPYING PERSONNEL WORK PLATFORM.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

9055-3031 REV. A

MAXIMUM OCCUPANCY THREE (3) PEOPLE.

DO NOT USE PERSONNEL WORK PLATFORM

WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM

CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY OR DEATH.

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO

MADE IN U. S. A.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN CAB.

9055-3033

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

REAR AXLE WHEEL END LUBE(4 PT.)

TIRES: 14.00x24(12 PLY) 65 PSI

FRONT AXLE

(5 GAL)

MOBIL 424

MOBIL 424

BATTERY & TERMINALS

DIESEL ENGINE

AIR CLEANER ELEMENTS

FUEL FILTERS

OIL FILTER

OIL (12 QT.)

DIESEL FUEL (40 GAL.)

HYD.TANK BREATHER/FILTER CAP

QUICK SWITCH (1) FITTING

TIRES: RADIAL 70 PSI

FRONT AXLE PIVOT (2) FITTINGS

ALL BEARINGS PADS

HEAD PIN (2) FITTINGS

ANNUALLY

OR

1500 HRS

DAILY

OR

10 HRS

WEEKLY

OR

50 HRS

EVERY

5WKS OR

250 HRS

3 MO.

OR

500 HRS

SERVICE INTERVALS

TYPE OR

EQUIVALENT

RADIATOR

3 GAL. WATER

3 GAL ANTI-FREEZE

WHEEL NUT TORQUE-350/400 FT-LBS

9134-3073 REV -

TIRES: 13.00x24(12 PLY) 65 PSI

CHECK

INSPECT

CHECK

REAR AXLE (12) FITTINGS

BOOM PIVOT (2) FITTINGS

TORQUE

CHECK

CHANGE

CYLINDER FITTINGS EACH END

RETRACT & EXTEND CABLE

SEE OPERATOR & MAINTENANCE MANUAL

CHANGE

CHANGE

CHANGE

FILL

OIL (47 GAL.)

CHECK

GREASE

GREASE

GREASE

GREASE

GREASE

GREASE

GREASE

CHECK

6 MO.

OR

1000 HRS

CHANGE

CHANGE

FRONT BOTTOM BEARING PADS

GREASE

CHECK

GREASE

BOOM SHEAVES (3) FITTINGS

HYDRAULIC SYSTEM

FILTERS

ETHYLENE GLYCOL

ANTI-FREEZE

SAE 15W-40-CD ***

DIESEL FUEL #2

GRADALL HANDLER

SERVICE INSTRUCTIONS

FOR: 534D-9, 534D-10

CONSULT DEALER FOR RECOMMENDATIONS AT EXTREME TEMPERATURES.

*

*

*

*

*

*

*

*

*

*

THIS CHART MUST BE USED IN CONJUNCTION WITH SERVICE MANUAL AND RECOMMENDED PROCEDURE.

CHECK INDICATOR ON HYDRAULIC FILTER. CHANGE FILTER IF NEEDLE IS IN YELLOW

AT FULL THROTTLE & AT OPERATING TEMPERATURE.

CHECK AIR CLEANER RESTRICTION INDICATOR. CLEAN OR CHANGE PRIMARY FILTER IF NECESSARY.

SAFETY ELEMENT TO BE CHANGED EVERY 3RD CHANGE OF PRIMARY FILTER ELEMENT.

IT IS RECOMMENDED THAT FILTER ELEMENTS AND FRONT AXLE LUBRICANT BE CHANGED AFTER

FIRST 50 HRS ON NEW OR REBUILT UNITS.

DAILY SERVICE MAY BE REQUIRED FOR OPTIMUM LIFE DEPENDING UPON APPLICATION SEVERITY.

MOBIL 424

CHECK

CHECK

CHECK

CHECK

CHECK

CHECK

- - - - - - - - - - - - - - - * * - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

- - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - -

- - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - -

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

SAMPLE ONLY - USE CHART IN CAB

*

* * * *

* * * *

* * * *

* * * *

* * * *