Auxiliary circuit relief valves, Uxiliary, Ircuit – Gradall 534D-6T Service Manual User Manual

Page 268: Elief, Alves

9.0

A

UXILIARY

C

IRCUIT

R

ELIEF

V

ALVES

•

CHECK # 1

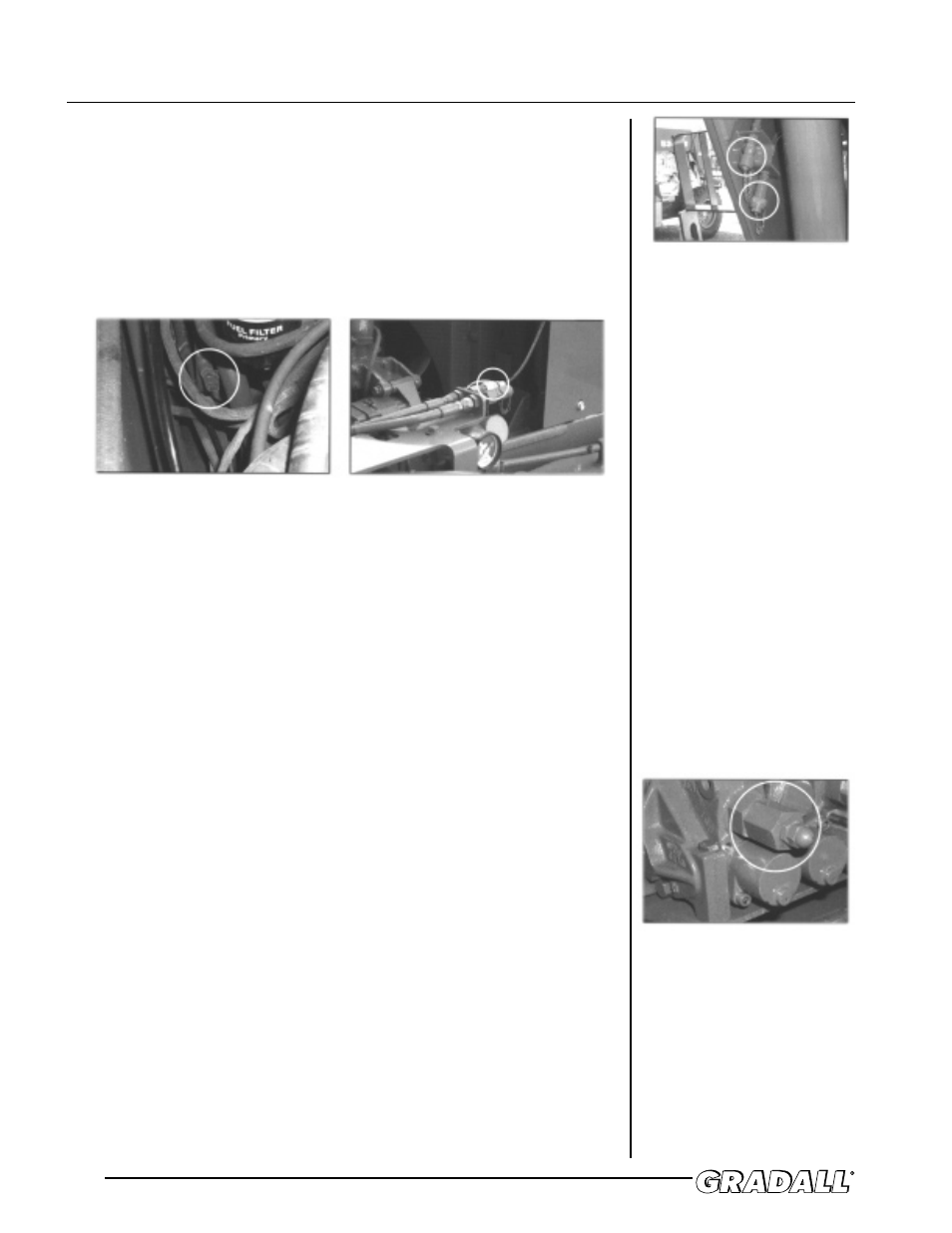

1. Inspect the quick-disconnect fittings at the boom head for signs

of leakage.

2. Replace any leaking fittings.

•

CHECK # 2

1. Install a 10,000 PSI gauge, hose and adapter to the test port on

the outlet tube of the main implement pump. Make sure you can

see the gauge from the operator’s cab.

2. With the park brake engaged and the transmission in “Neutral”,

start the material handler.

3. With the engine running at low idle (800-900 RPM) and holding

the Auxiliary Control Lever fully forward to pressurize Work Port

A, observe the gauge. The gauge should read 2000 ± 100 PSI.

4. Release the lever.

5. Observe the gauge while holding the Auxiliary Control Lever

fully backward to pressurize Work Port B. The gauge should read

2000 ± 100 PSI.

6. Release the lever.

•

ADJUST

1. Before attempting any adjustment, you must switch the engine

off! Also, make sure the park brake is still engaged.

2. If necessary, loosen the locknut on the given circuit’s relief valve.

3. Turn the adjusting screw clockwise to increase pressure;

counter-clockwise to reduce pressure.

522, 524, 532C-6, 534C-6 and 534C-6T

MAIN IMPLEMENT TEST PORT

ALL OTHER MODELS

MAIN IMPLEMENT TEST PORT

BOOM-HEAD QUICK-DISCONNECT

FITTINGS

AUXILIARY RELIEF

NOTE!

The location of the main

implement test port varies by

machine vintage.