Bunn -O-MATIC ULTRA-1 User Manual

Page 53

53

FIG. 64 TORQUE SENSOR CIRCUIT

BOARD TERMINALS

SERVICE (cont.)

TORQUE SENSOR CIRCUIT BOARD

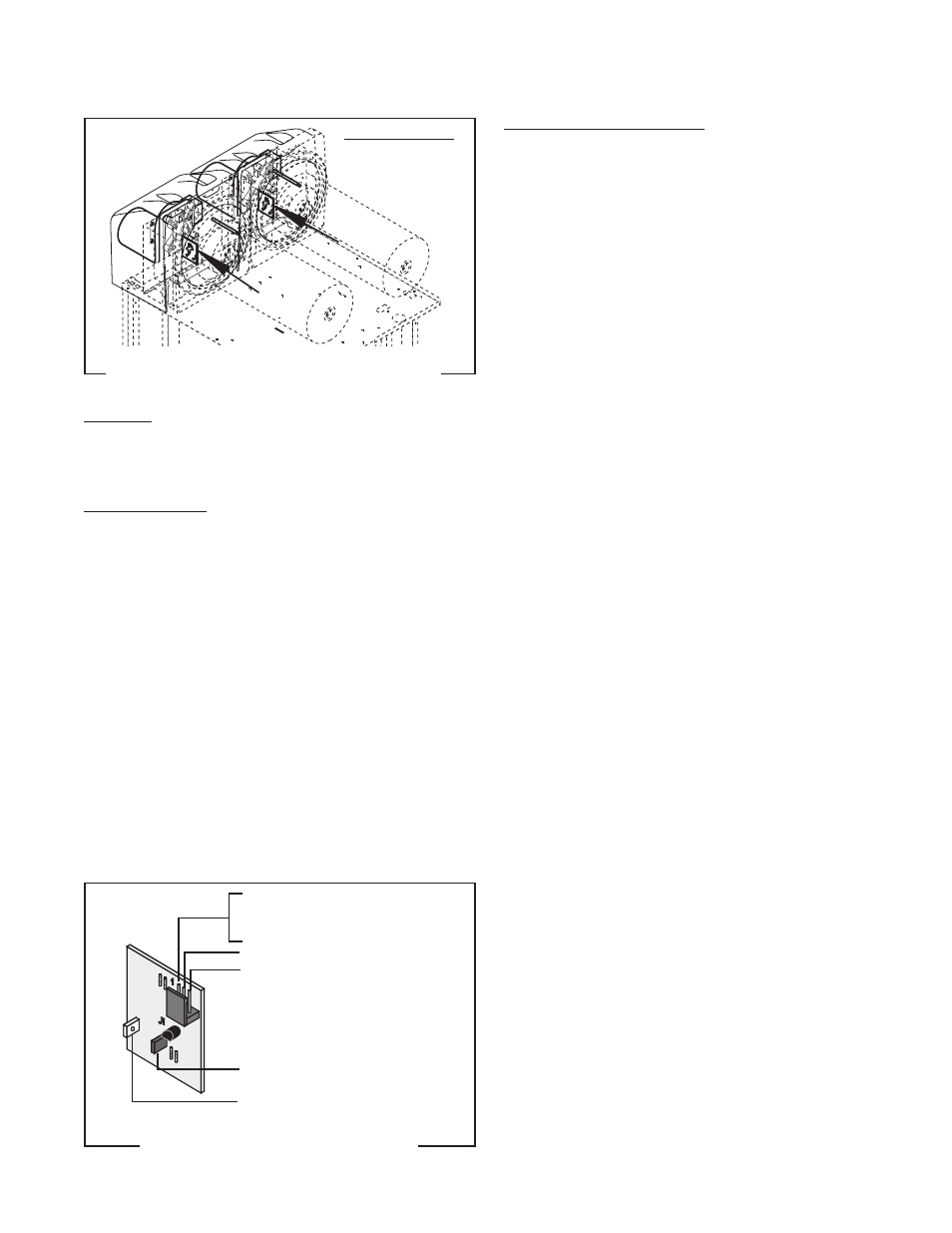

FIG. 63 TORQUE SENSOR CIRCUIT BOARD

P1341

Location:

The torque sensor circuit board is located on the rear

of the cooling drum mount just left of center.

Test Procedures:

1. Place black meter lead at J1-3 (common) and red

lead at J1-1 (signal). Set meter to 10 - 20volts DC

scale. Turn on power switch.

DO NOT TURN ON AUGERS!

2. Using a strip of paper, momentarily block the light

path between red LED and white phototransistor.

If the meter displays 5vdc when blocked and 0v

when unblocked, then the Torque Sensor is good.

If there is no 5vdc reading, verify that both red and

white sensors are clean.

3. If there is still no 5vdc reading when blocked, place

the red meter lead at J1-2 and verify that there is

4.5vdc supplied to Torque Sensor. If there is no

5vdc supplied, check wiring between control board

and Torque Sensor. If wiring is ok, then replace the

main control board.

Removal and Replacement:

1. Remove the two #8-32 locking screws securing the

auger motor cover to the cooling drum mount.

2. Remove the cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right

side of the auger motor mounting bracket securing

the auger motor run capacitor. Set capacitor aside

with wires attached.

4. Disconnect the auger motor plug from the connector

on the main wiring harness.

5. Remove the three remaining #8 locking screws

securing the auger motor mounting bracket to

cooling drum mounting bracket.

6. Remove motor with mounting bracket, split pin/

torsion spring bearings as an assembly and set

aside for reassembly.

NOTE: When removing or installing the motor be sure

the split pin in the motor shaft is turned to a position

that will clear the torque sensor circuit board.

7. Disconnect the plug from the dispenser main wiring

harness to the torque sensor circuit board.

8. Remove the #8-32 locking screw and washer secur-

ing torque sensor circuit board to the cooling drum

mount.

9. Remove torque sensor circuit board and discard.

10. Install new torque sensor circuit board in the slot

in the rear of the cooling drum mount and secure

with a #8-32 locking screw and washer.

11. Refer to Fig. 42 and reconnect the wires.

12. Reinstall motor with mounting bracket, drip tray,

split pin and torsion spring bearings using three

#8 locking screws onto the cooling drum bracket.

13. Install the auger motor capacitor on the lower

right side of the auger mounting bracket using the

remaining #8 locking screw.

14. Connect the auger motor terminal to the terminal

on the main wiring harness.

15. Refer to Fig. 64 when reconnecting the wires.

16. Position the auger motor cover on the cooling

drum mount and secure with two #8-32 locking

screws.

J1

1

1. Ultra-2 Left Signal (WHI/GRY)

1. Ultra-2 Right Signal (WHI/GRN)

1. Ultra-1 Signal (WHI/GRY)

2. (+) 5vdc (BLU)

3. (-) common (WHI/BLK)

L.E.D.

PHOTOTRANSISTOR

ULTRA-2 shown

41084 102709