Bryant DURAPAC 580F User Manual

Page 39

—

39

—

V. ECONOMI$ER IV ADJUSTMENT

Refer to Optional EconoMi$er IV section on page 15.

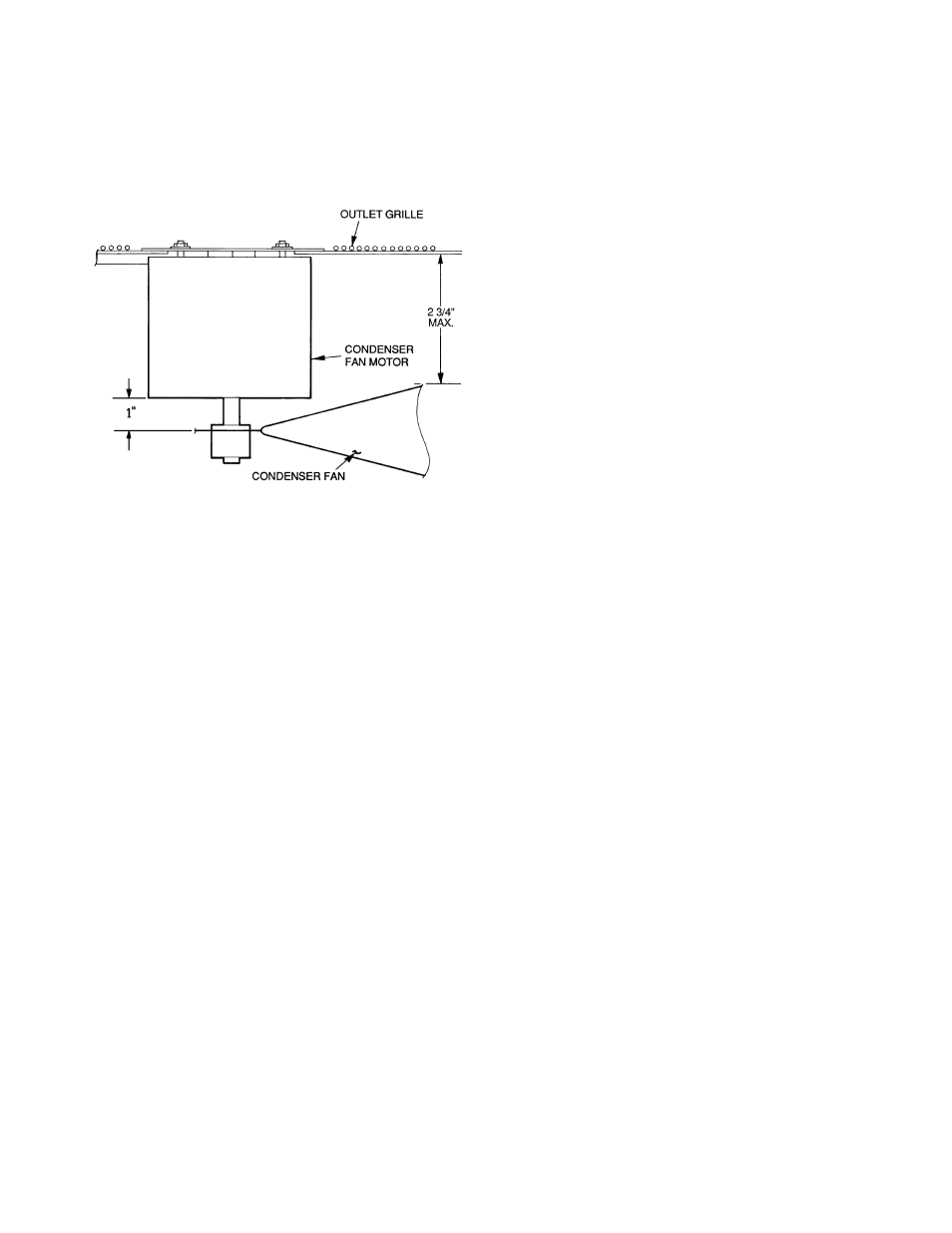

VI. CONDENSER-FAN ADJUSTMENT (Fig. 39)

Shut off unit power supply. Remove condenser-fan assembly

(grille, motor, and fan) and loosen fan hub setscrews. Adjust

fan height as shown in Fig. 39. Tighten setscrews and

replace condenser-fan assembly.

VII. REFRIGERANT CHARGE

Amount of refrigerant charge is listed on unit nameplate

(also refer to Table 1). Compressor must run a minimum of

10 minutes before adjusting or checking charge.

Unit panels must be in place when unit is operating during

charging procedure.

A. No Charge

Use standard evacuating techniques. After evacuating sys-

tem, to 500 microns, weigh in the specified amount of refrig-

erant. (Refer to Table 1.)

B. Low-Charge Cooling

Using Cooling Charging Charts, Fig. 40-43, vary refrigerant

until the conditions of the appropriate chart are met. Note

the charging charts are different from type normally used.

Charts are based on charging the units to the correct super-

heat for the various operating conditions. Accurate pressure

gage and temperature sensing device are required. Do not

use pocket type thermometers for measuring surface temper-

atures as they are not designed for this type of measure-

ment. Connect the pressure gage to the service port on the

suction line. Mount the temperature sensing device on the

suction line and insulate it so that outdoor ambient tempera-

ture does not affect the reading. Indoor-air cfm must be

within the normal operating range of the unit.

C. To Use Cooling Charging Chart

Take the outdoor ambient temperature and read the suction

pressure gage. Refer to chart to determine what suction tem-

perature should be. If suction temperature is high, add

refrigerant. If suction temperature is low, carefully recover

some of the charge. Recheck the suction pressure as charge

is adjusted.

EXAMPLE: (Fig. 42)

Outdoor Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 F

Suction Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 psig

Suction Temperature should be . . . . . . . . . . . . . . . . . . . 76 F

(Suction Temperature may vary 5 F.)

VIII. FLUE GAS PASSAGEWAYS

To inspect the flue collector box and upper areas of the heat

exchanger:

1. Remove the combustion blower wheel and motor

assembly according to directions in Combustion-Air

Blower section on page 39.

2. Remove the flue cover to inspect the heat exchanger.

3. Clean all surfaces as required using a wire brush.

IX. COMBUSTION-AIR BLOWER

Clean periodically to assure proper airflow and heating effi-

ciency. Inspect blower wheel every fall and periodically during

heating season. For the first heating season, inspect blower

wheel bimonthly to determine proper cleaning frequency.

To access burner section, slide the sliding burner partition

out of the unit.

To inspect blower wheel, shine a flashlight into draft hood

opening. If cleaning is required, remove motor and wheel as

follows:

1. Slide burner access panel out.

2. Remove the 7 screws that attach induced-draft motor

housing to vestibule plate (Fig. 44).

3. The blower wheel can be cleaned at this point. If ad-

ditional cleaning is required, continue with Steps 4

and 5.

4. To remove blower from the motor shaft, remove

2 setscrews.

5. To remove motor, remove the 4 screws that hold the

motor to mounting plate. Remove the motor cooling

fan by removing one setscrew. Then remove nuts that

hold motor to mounting plate.

6. To reinstall, reverse the procedure outlined above.

X. LIMIT SWITCH

Remove blower access panel (Fig. 7). Limit switch is located

on the fan deck.

XI. BURNER IGNITION

Unit is equipped with a direct spark ignition 100% lockout

system. Integrated Gas Unit Controller (IGC) is located in the

control box (Fig. 11). The IGC contains a self-diagnostic LED

(light-emitting diode). A single LED on the IGC provides a

visual display of operational or sequential problems when the

power supply is uninterrupted. When a break in power occurs,

the IGC will be reset (resulting in a loss of fault history) and

the indoor (evaporator) fan ON/OFF times will be reset. The

LED error code can be observed through the viewport. During

servicing refer to the label on the control box cover or Table 34

for an explanation of LED error code descriptions.

If lockout occurs, unit may be reset by interrupting power

supply to unit for at least 5 seconds.

Fig. 39 — Condenser-Fan Adjustment