Appendix i-a – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 63

APPENDIX I-A

APPENDIX I- Installation and Disassembly Instructions for Goulds ANSI B15.1

Coupling Guards

A — All Power Ends Except Those with Optional Air Cooling Package . . . . . . . . 63

B — Power Ends with Optional Air Cooling Package . . . . . . . . . . . . . . . . . . 67

APPENDIX II - Dial Indicator (Rim-and-Face) Alignment Procedure . . . . . . . . . . 71

APPENDIX III - Removal and Assembly of Back Pull-Out Assembly . . . . . . . . . . 75

INSTALLATION AND DISASSEMBLY

INSTRUCTIONS FOR GOULDS ANSI B15.1

COUPLING GUARDS

(CASING MOUNT MOTOR SUPPORT ONLY)

!

The coupling guard used in an ATEX classified

environment must be constructed from a non-

sparking material.

All Power Ends Except Those Mounted with

Optional Air Cooling Package

s

!

WARNING

Before installation or disassembly of the coupling

guard is performed, the driver must be de-energized,

the driver controller / starter put in a locked-out

position and a caution tag placed at the controller /

starter indicating the disconnect. Replace coupling

guard before resuming normal operation of the pump.

ITT Industries - Goulds Pumps assumes no liability for

avoiding this practice.

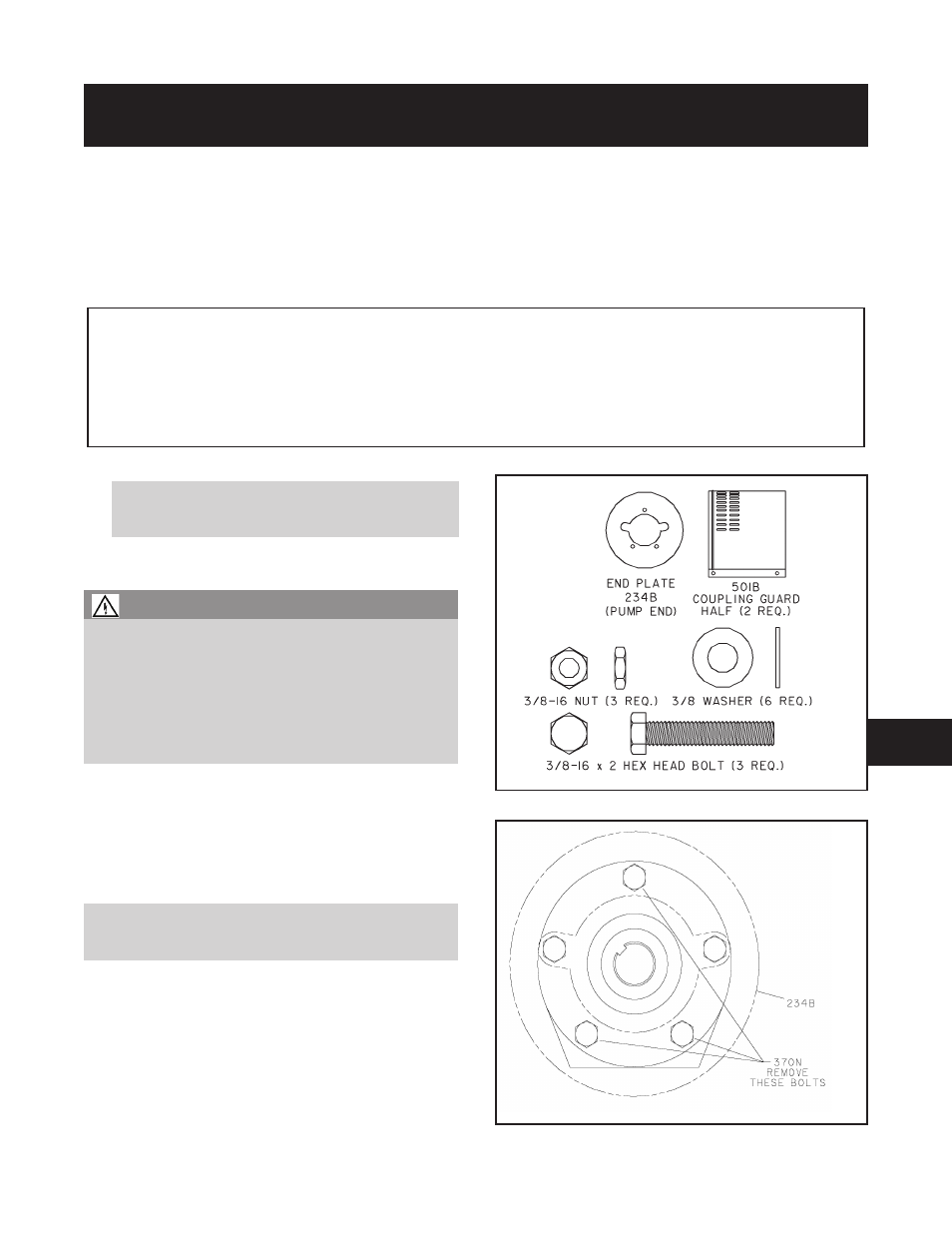

Simplicity of design allows complete assembly of the coupling

guard, including the end plate (pump end), in about fifteen

minutes. If the end plate is already in place, assembly can be

accomplished in about five minutes. Fig. I-A-1 shows the

coupling guard components.

INSTALLATION

NOTE: If end plate (pump end) is already installed,

make any necessary coupling adjustments and then

proceed to Step 7.

1.

Remove spacer portion of coupling. Refer to coupling

manufacturer’s instructions for assistance.

2.

If the coupling hub diameter is larger than the diameter

of the opening in the end plate (234B), remove the

coupling hub.

3.

Remove three thrust bearing end cover/bearing frame

screws (370N) as indicated in Fig. I-A-2.

3910-

11th IOM 5/08

63

Fig. I-A-1

Fig. I-A-2

8