Piping, Warning, Table 4 piping flange alignment – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 19: Suction piping, Caution

PIPING

Guidelines for piping are given in the “Hydraulic Institute

Standards,” available from:

Hydraulic Institute

9 Sylvan Way

Parsippany, NJ 07054

and in API RP 686, and must be reviewed prior to pump

installation.

s

!

WARNING

Never draw piping into place by forcing at the flanged

connections of the pump. This may impose dangerous

strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely affect the

operation of the pump resulting in physical injury and

damage to the equipment.

!

Flange loads from the piping system, including

those from thermal expansion of the piping, must

not exceed the limits of the pump. Casing deforma-

tion can result in contact with rotating parts which

can result in excess heat generation, sparks and

premature failure.

1.

Piping runs should be as short as possible to minimize

friction losses.

2.

It is suggested that expansion loops be properly

designed and installed in suction and/or discharge lines

when handling liquids at elevated tempera- tures, so

thermal expansion of piping will not draw pump out of

alignment.

3.

The piping should be arranged to allow pump flushing

prior to removal of the unit on services handling

hazardous liquids.

4.

Carefully clean all pipe parts, valves and fittings, and

pump branches prior to assembly.

5.

All piping must be supported independently of, and

line up naturally with, the pump flanges. Table 2

shows piping flange alignment criteria.

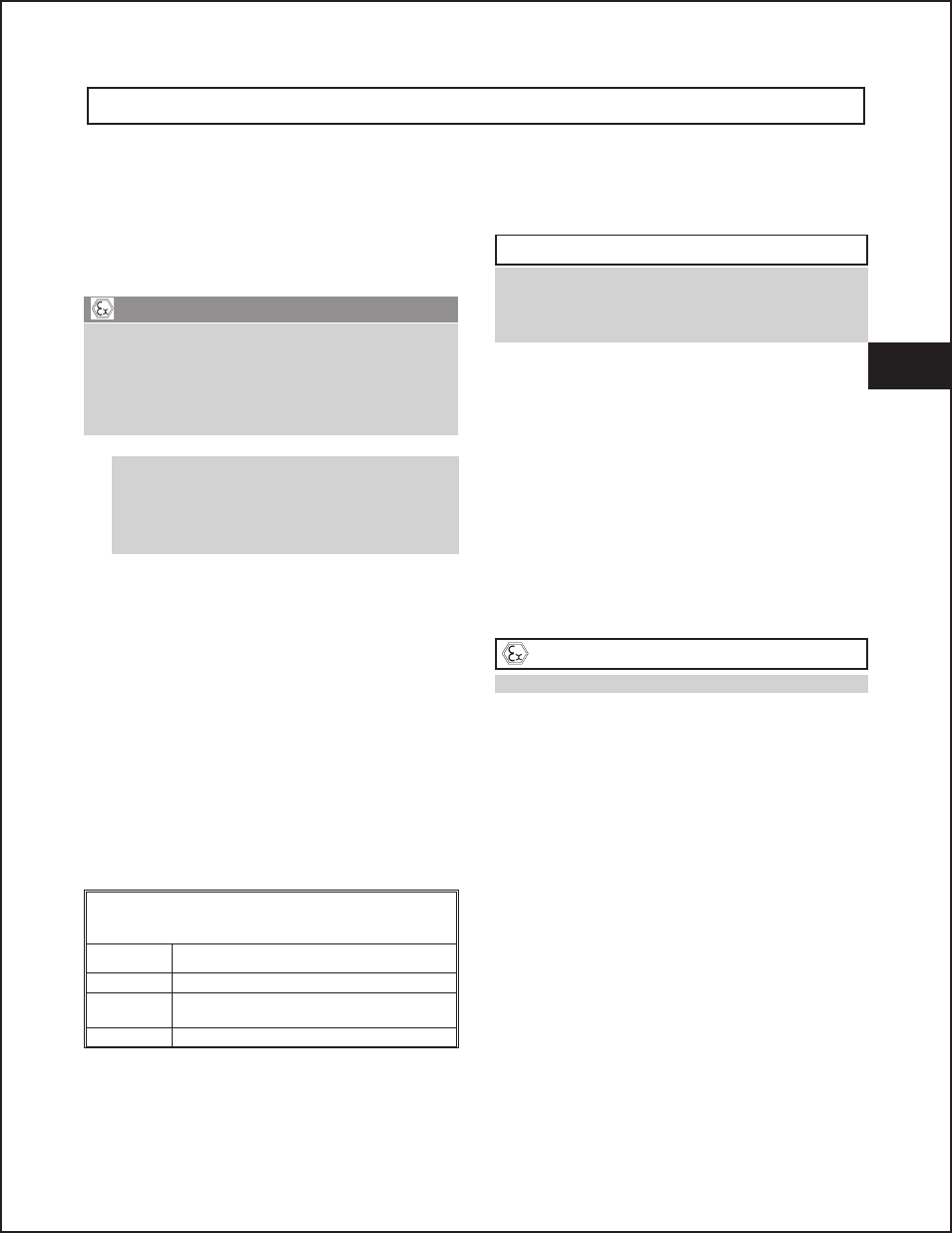

Table 4

Piping Flange Alignment

Type

Criteria

Axial

Flange gasket thickness

± 0.8 mm (.03 in.).

Parallel

0.001 mm/mm (.001 in./in.) of flange diameter

to a maximum of 0.8 mm (.03 in.).

Concentric

Flange bolts should easily install by hand.

In no case should loads on the pump flanges exceed the

limits stated in API Standard 610,

11th Edition (ISO

13709).

6.

Bottom of casing should be supported by a solid

foundation or casing feet should be used.

SUCTION PIPING

$

CAUTION

NPSH

A

must always exceed NPSH

R

as shown on

Goulds performance curves received with order.

(Reference Hydraulic Institute for NPSH and pipe

friction values needed to evaluate suction piping).

Properly designed and installed suction piping is a necessity for

trouble-free pump operation. Suction piping should be flushed

BEFORE connection to the pump.

1.

Use of elbows close to the pump suction flange should

be avoided. There should be a minimum of two (2)

pipe diameters of straight pipe [five (5) pipe diameters

is preferred] between the elbow and suction inlet.

Where used, elbows should be long radius.

2.

Use suction pipe one (1) or two (2) sizes larger than

the pump suction, with a reducer at the suction flange.

Suction piping should never be of smaller diameter

than the pump suction.

3.

Reducers, if used, should be eccentric and located at

the pump suction flange with sloping side down.

$

CAUTION

Pump must never be throttled on suction side.

4.

A suction screen should be installed prior to initial

start-up and when suction system has been opened for

work. The screen should be of the cone type with a

net area equal to at least three (3) times the cross

sectional area of the suction pipe. The mesh of the

screen should be sized to prevent particles larger than

1.6 mm (1/16 in.) from entering the pump and should

be installed in a spool piece to allow removal for

cleaning. The screen should remain in the system until

periodic inspection shows system is clean.

5.

Separate suction lines are recommended when more

than one pump is operating from the same source of

supply.

Suction Lift Conditions

1.

Suction pipe must be free from air pockets.

2.

Suction piping must slope upwards to pump.

3.

All joints must be air tight.

4.

A means of priming the pump must be provided.

3910-1

1th IOM 5/08

19

3