Goulds Pumps 3420 - IOM User Manual

Page 73

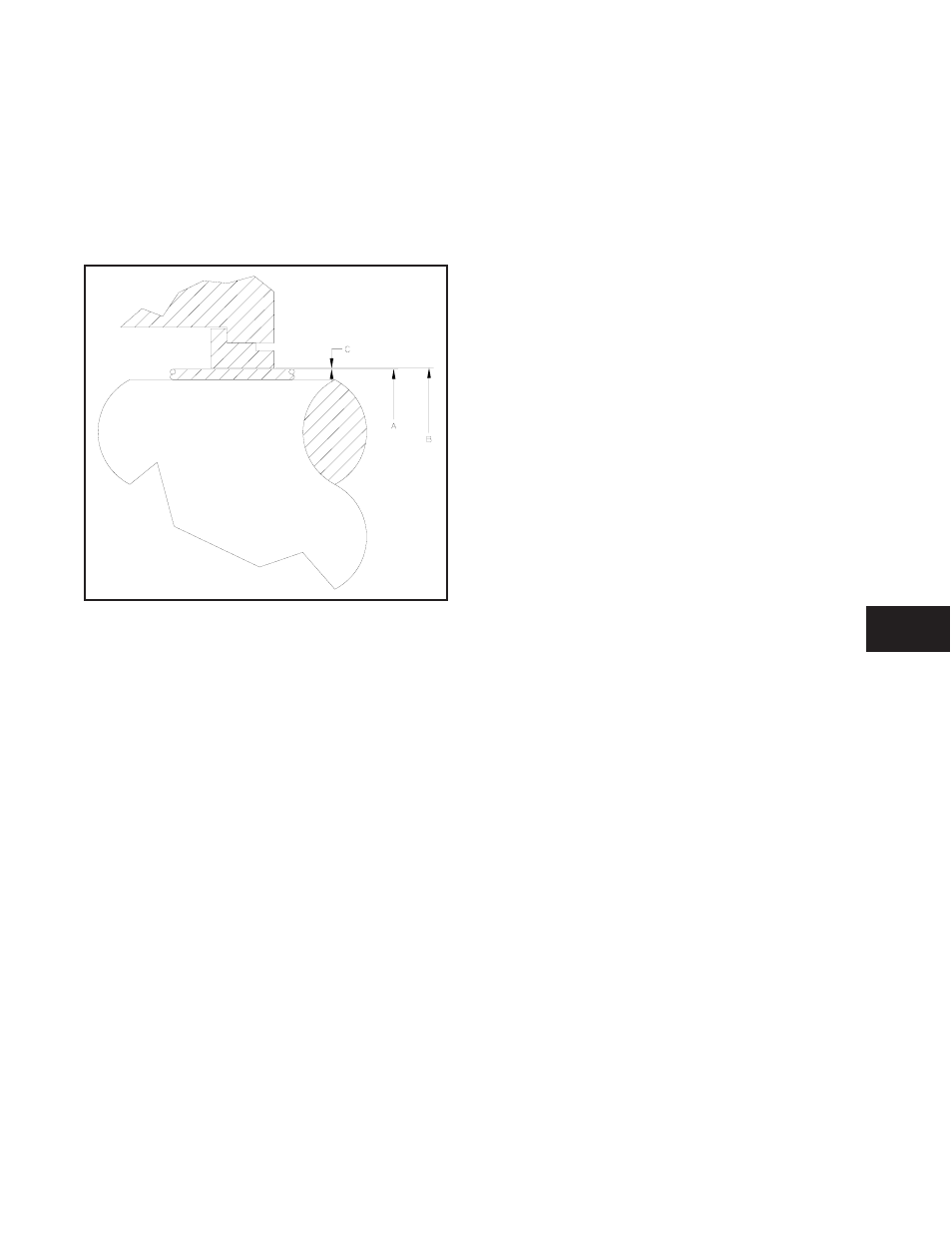

SHAFT SLEEVES

The shaft sleeve (126) surface in the stuffing box area must

be smooth and free of grooves. If grooved, replace the

sleeve. The O-ring groove must be in good condition.

Check the diametrical clearance between the sleeve and the

stuffing box bushing. See Figure 54. The original

clearance is shown in Table 8. If the clearance has

increased more than .030 in. (.762 mm). The shaft sleeve

and/or the stuffing box bushing should be replaced.

BEARING HOUSINGS

Visually inspect the interior of the housings (134, 134A,

134D, or 166) for damage, cracks, corrosion, scale, or

debris. Remove all loose and foreign materials. Make sure

all lubrication passages are clear. Inspect the bearing bores

according to the tolerances in Table 10. Replace the

housings if they are out of tolerance.

BEARINGS

Ball and roller bearings (112, 168, 409 and 410) should be

inspected for contamination and damage. The condition of

the bearings will provide useful information on operating

conditions in the bearing housing. Lubricant condition and

residue should be noted. Oil analysis is often helpful in

diagnosing conditions and/or problems. Bearing damage

should be investigated to determine the cause. If the cause

is not normal wear, it should be corrected before the pump

is returned to service. It is not recommended that

anti-friction bearings be reused after they have been

disassembled and inspected.

3420 IOM 8/09

69

Fig. 54

6