Alignment troubleshooting grout baseplate, Piping, Alignment check – Goulds Pumps 3420 - IOM User Manual

Page 25: General

ALIGNMENT TROUBLESHOOTING

GROUT BASEPLATE

1.

Clean areas of baseplate that will contact grout. Do

not use oil-based cleaners because grout will not bond

to it. Refer to grout manufacturers instructions.

2.

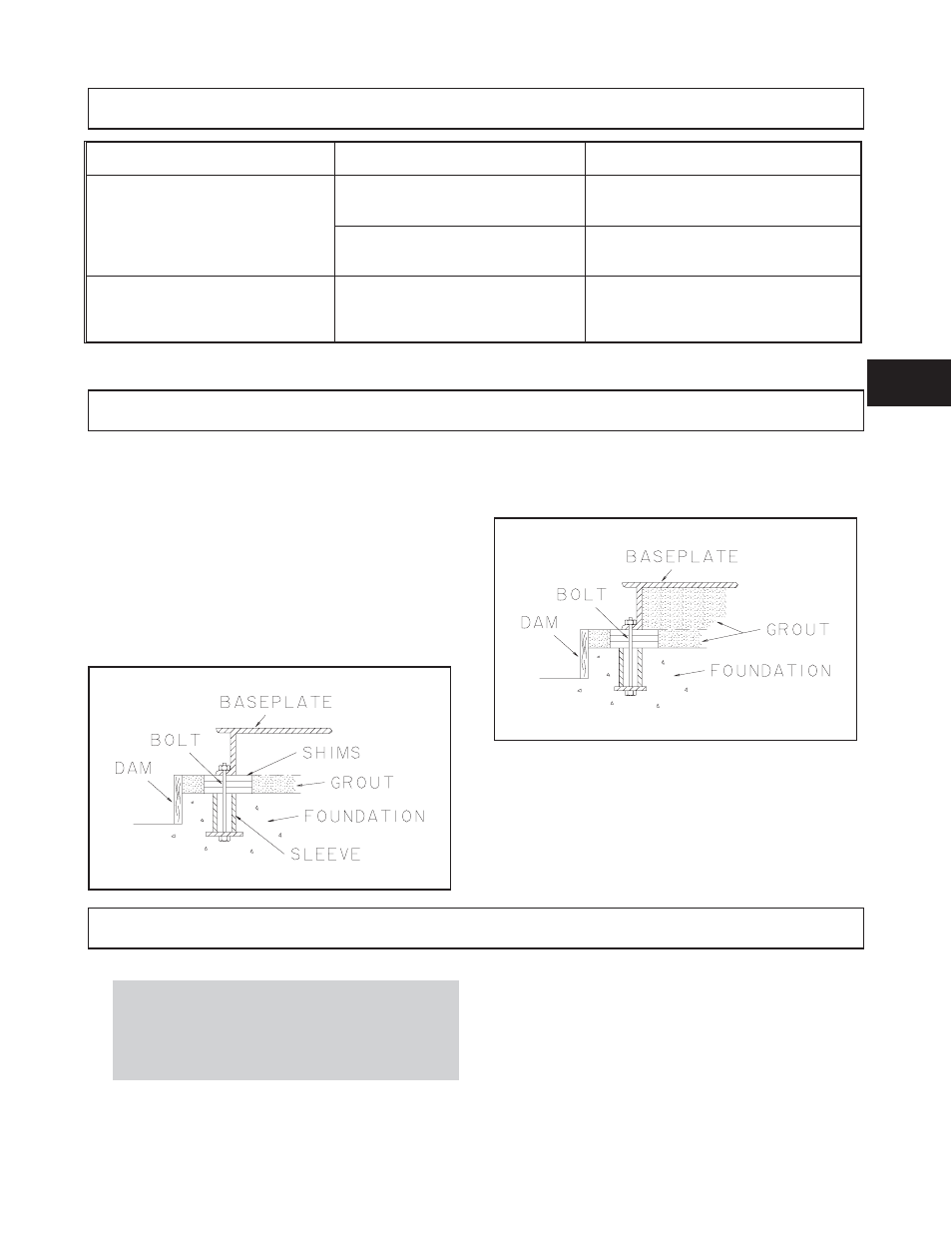

Build dam around foundation. Thoroughly wet

foundation (Fig. 11).

3.

Pour grout through grout hole in baseplate, up to level

of dam. Remove air bubbles from grout as it is poured

by puddling, using a vibrator, or pumping the grout

into place. Non-shrink grout is recommended.

4.

Allow grout to set.

5.

Fill remainder of baseplate with grout. Remove air as

before (Fig. 12).

6.

Allow grout to set at least 48 hours.

7.

Tighten foundation bolts.

ALIGNMENT CHECK

Re-check alignment before continuing, using methods

previously described.

PIPING

!

Flange loads from the piping system, including

those from thermal expansion of the piping, must

not exceed the limits of the pump. Casing

deformation can result in contact with rotating parts

and result in excess heat generation, sparks and

premature failure.

GENERAL

Guidelines for piping are given in the “Hydraulic Institute

Standards” available from: Hydraulic Institute, 30200

Detroit Road, Cleveland, OH 44145-1967 and must be

reviewed prior to pump installation.

3420 IOM 08/09

21

Fig. 11

Fig. 12

3

Problem

Probable Cause

Remedy

Cannot obtain horizontal (Side-to-Side)

alignment, angular or parallel

Driver feet bolt bound.

Loosen pump hold-down bolts and slide

pump and driver until horizontal alignment is

achieved.

Baseplate not leveled properly, probably

twisted.

Determine which corner(s) of the baseplate

are high or low and remove or add shims at

the appropriate corner(s) and realign.

Cannot obtain vertical (Top-to-Bottom)

alignment, angular or parallel

Baseplate not leveled properly,

probably bowed.

Determine if center of baseplate should be

raised or lowered and correct by evenly add-

ing or removing shims at the center of the

baseplate.