Warning, Shaft sealing – Goulds Pumps 3420 - IOM User Manual

Page 31

Grease Lubrication: Pumps are shipped with grease

installed, sufficient for 2,000 hours operation. It is

recommended that additional or replacement lubrication be

added after every 2,000 hours or at three month intervals.

The lubricant should be renewed in the housings at least

once each year. See Table 5 (p. 35) for recommended

greases.

If the pump is put into operation after a prolonged

shut-down, flush out the bearing housings with a light oil

to remove any contaminants. During flushing, rotate the

shaft slowly by hand. Finally, flush the bearing housing

with the proper lubricating oil to ensure oil quality after

cleaning.

s

!

WARNING

Operation of the unit without proper lubrication will

cause bearing failure and pump seizure.

SHAFT SEALING

!

Packed stuffing boxes are not allowed in an ATEX

classified environment.

Packed Stuffing Box: Pumps are shipped without packing,

lantern ring, or split gland installed. These are included in

the box of fittings shipped with the pump and must be

installed before start-up.

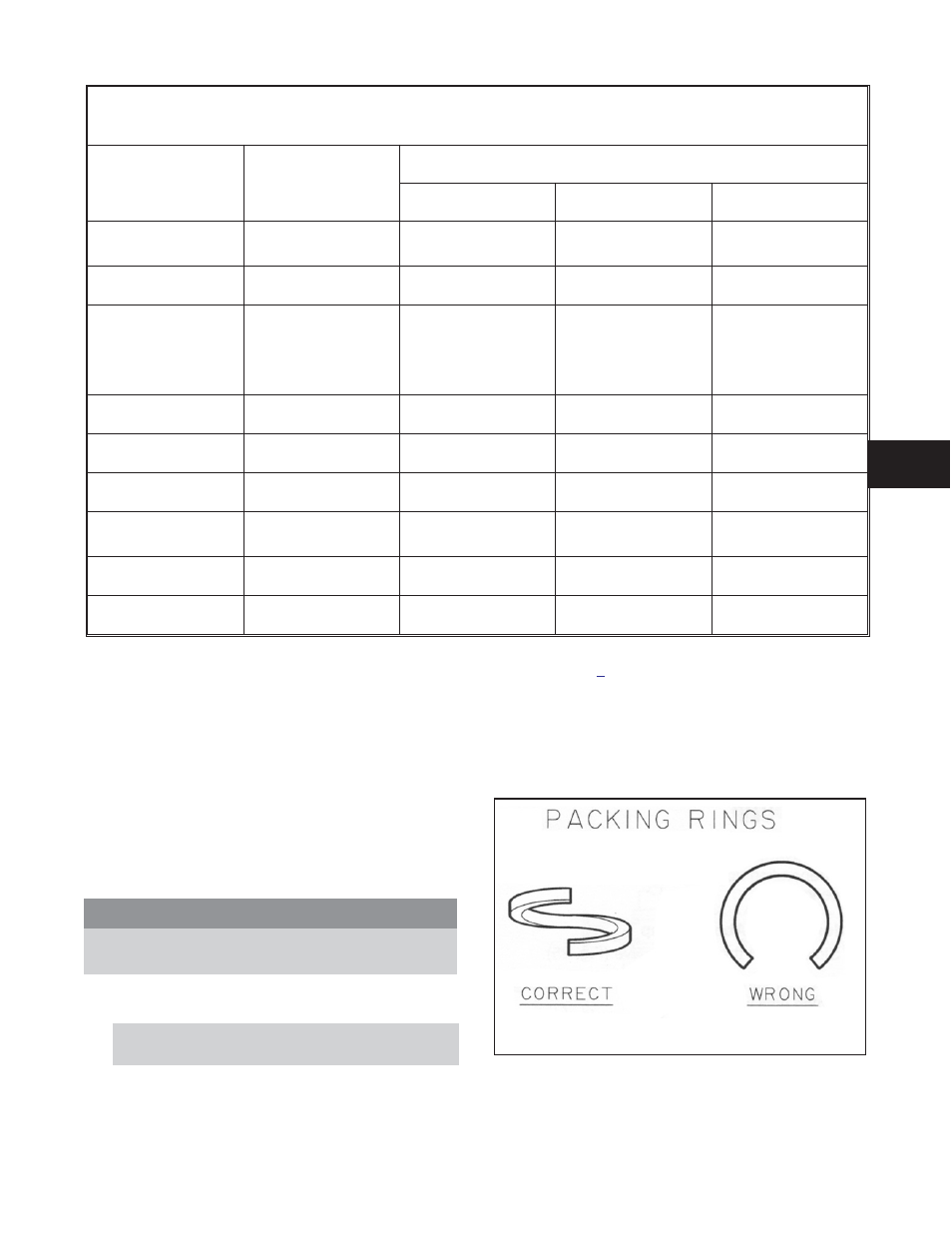

Installation of Packing:

1.

Carefully clean the stuffing box bore.

2.

Twist the packing just enough to get it around the

shaft (Fig 15).

3.

Insert packing, staggering the joints in each ring by

90° degrees.

3420 IOM 8/09

27

4

Table 2

Oil Settings - Inches (mm)

Group

Sizes

Flood Oil Ball / Ring Oil Ball / Ring Oil Roller

Oiler Size

“A” in (mm)

“B” in (mm)

SX

12 x 14-15

# 3

4 OZ.

27/32 (21.4)

3/4 (19)

16 x 18-17H

MX

18 x 20-20

# 3

4 OZ.

27/32 (21.4)

3/4 (19)

M

16 x 18-30

# 10

16 OZ.

9/16 (14.3)

1/2 (12.7)

18 x 20-30

20 x 24-24

20 x 24-30

M

Modified

20 x 24-28

# 10

16 OZ.

27/32 (21.4)

3/4 (19)

-

18 x 20-24

# 10

16 OZ.

27/32 (21.4)

3/4 (19)

L

24 x 30-32

# 10

16 OZ.

7/8 (22.2)

13/16 (20.6)

LDS

30 x 30-31

# 10

16 OZ.

9/16 (14.3)

1/2 (12.7)

30 x 30-38

XL

30 x 36-42

20x30-42

# 10

16 OZ.

9/16 (14.3)

1/2 (12.7)

XXL

36x42-52

#10

16 OZ.

3/8 (9.7)

7/16 (11.1)

Fig. 15