Initial oil lubrication of new bearings, Caution, Table 4 – Goulds Pumps 3410 - IOM User Manual

Page 40: Bearing temperatures, Emergency ball bearing replacement, Warning, Bearing conditions

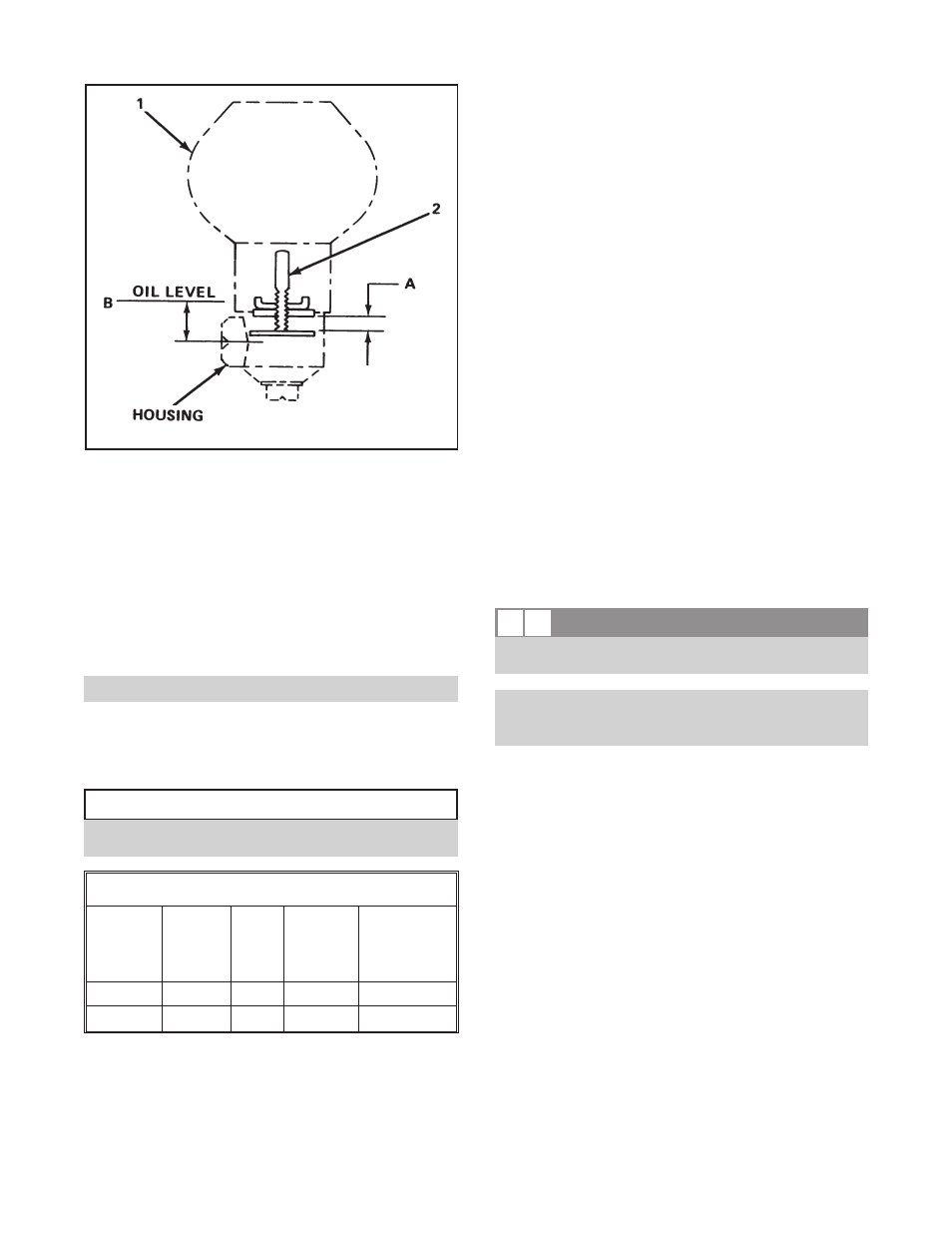

INITIAL OIL LUBRICATION OF

NEW BEARINGS

1.

Remove oiler (1), Fig. 34.

2.

Remove adjustment assembly (2) from oiler.

3.

Adjust bars to dimension A, as required, Table 4.

4.

Lock in position.

5.

Replace adjustment assembly in oiler.

6.

Install oiler.

NOTE: Never fill through oil vent or oiler housing.

7.

Fill each oiler bottle with oil and replace in oiler

housing. Oil reservoir in bearing housing is filled

when oil remains visible in bottle. Several fillings of

bottle may be required.

$

CAUTION

Bar adjust must be adjusted as stated in step 3 above. If

not adjusted properly, bearing will not be lubricated.

Table 4

GROUP

A

in. (mm)

B

in. (mm)

OILER

SIZE

oz. (ml)

CASING

CAPACITY

ounces (ml)

S & M

9/16 (14.5) 1/2 (13) #5 - 8 (204)

9 (266)

L & XL

9/16 (14.5) 1/2 (13) #5 - 8 (204)

16-1/2 (489)

BEARING TEMPERATURES

All bearings operate at some temperature above that of the

surrounding atmosphere, unless cooled. Heat is generated

within the bearing due to rolling friction, churning of oil,

and the drag of the race.

Do not use the human hand as a thermometer. A

temperature which feels hot varies from 120°F (49°C) to

130°F (54°C) depending upon the individual. Above this

temperature, the human hand is worthless in estimating

temperature.

Bearing temperatures up to 180°F (82°C) are normal.

Determine the temperature accurately by placing a contact

type thermometer against the bearing housing. It should be

recorded in a convenient location for reference. The

stability of the temperature, rather than the number of

degrees, is the best indication of normal operation. A

sudden increase in temperature is an indication of danger

and a signal to investigate. The unit should be checked for

abnormal hydraulic operation and unnecessary loads, such

as coupling misalignment, etc. See Troubleshooting.

EMERGENCY BALL BEARING

REPLACEMENT

If the outboard end ball bearing needs replacement and it is

not desirable to overhaul the entire pump, the bearing can

be replaced without disassembling the entire pump. See

Disassembly and Reassembly section for details.

s

!

WARNING

Lock out power driver before starting this procedure to

prevent accidental turning.

NOTE: Coupling end bearing cannot be replaced in

this manner unless pump or driver is removed from

bedplate or spacer coupling is used.

BEARING CONDITIONS

The life of a bearing can be drastically reduced if

contaminated with even a small amount of dust or dirt. All

bearing assembly operations should be done in as dust-free

an atmosphere as possible. All tools, as well as hands,

should be kept clean.

If new bearings are to be installed, they should not be

unwrapped, cleaned, or washed until ready for installation.

If old bearings are contaminated, they should be replaced.

Washing bearings does not guarantee cleanliness and is

risky at best. If new bearings are not readily available and

immediate reassembly is necessary, contaminated bearings

can be cleaned as follows:

1.

Pour one or two quarts of clean, water-free kerosene

into a clean pail. Dip the bearings into kerosene and

agitate slowly.

38

3410 IOM 1/2010

Fig. 34

A B