Lubrication, Grease lubrication, Caution – Goulds Pumps 3410 - IOM User Manual

Page 39: Oil lubrication, Lubricant recommendations

LUBRICATION

!

Throughout this section on bearing lubrication,

different pumpage temperatures are listed. If the

equipment is ATEX certified and the listed

temperature exceeds the applicable value shown in

Table 1 under SAFETY, then that temperature is not

valid. Should this situation occur, please consult

with your ITT/Goulds representative.

GREASE LUBRICATION

Grease lubricated ball bearings are standard on all Model 3410

pumps. These units can be identified by grease fittings located on

the bearing housing.

• Grease should be of sodium or lithium base, NLGI #2

consistency. DO NOT USE GRAPHITE.

• It is suggested that additional or replacement lubricant

be added after 2,000 hours or at three-month intervals.

• Lubricant should be renewed in housings at least once

annually. This should be done when an overhaul is

made.

• To grease bearings, proceed as follows:

$

CAUTION

Grease lubricated bearings are lubricated at the

factory. Do not grease at too frequent intervals.

1.

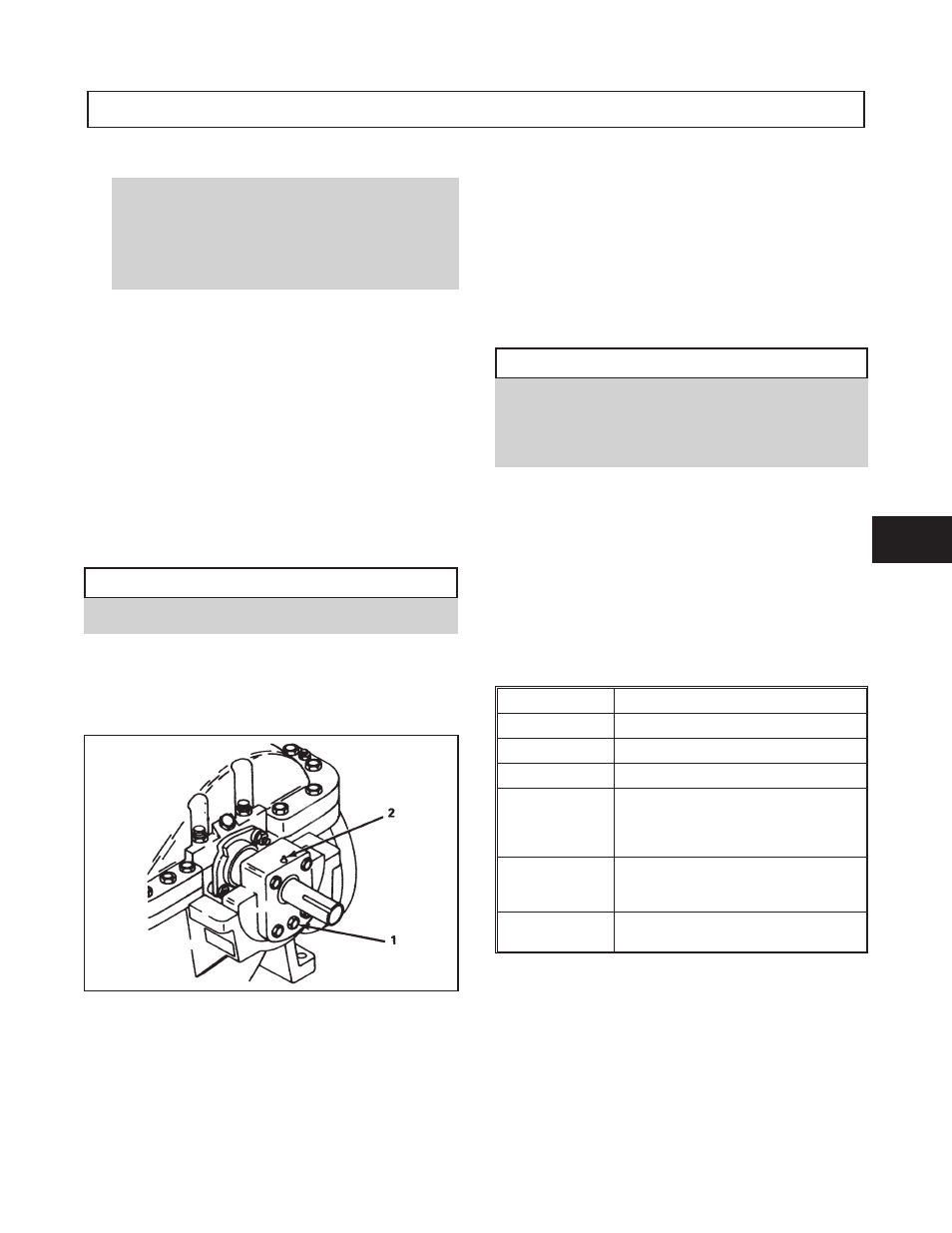

Remove relief plug (1) on bearing housing. See Fig.

33.

2.

Insert grease through fitting (2) until grease appears

through relief plug hole.

3.

Repeat steps 1 and 2 on other bearing.

4.

Operate unit approximately 1/2 hour with relief holes

open to prevent overgreasing. After 1/2 hour, replace

relief plugs on both bearing housings.

OIL LUBRICATION

Flood oil lubricated ball bearings are optional on all Model

3410 units. Oil lubricated pumps are supplied with oilers

which maintain a constant oil level in the bearing housing.

$

CAUTION

Under normal operating conditions, an oil of 300 SSU

viscosity at 100°F (38°C) (approximately SAE-20)

should be used, (see lubricant recommendations

below). For extreme conditions refer to the factory or a

lubrication expert for a recommendation.

Fill auto oiler bottles on both bearing housings with the

proper grade of oil and place on oiler housing. Oil reservoir

in bearing housing is filled when a constant oil level

remains in the bottle. Several fillings of bottle are required

for initial lubrication. Never fill through the oiler housing

without use of the oiler bottle.

LUBRICANT RECOMMENDATIONS

The following have been recommended by various

suppliers as meeting their basic requirements:

EXXON

TERESSTIC 68

CHEVRON

GTS OIL 68

MOBIL

MOBIL DTE 26 300 SSU @ 100°F

PHILLIPS

MANGUS OIL GRADE 315

TEXACO

BELOW 80°F: REGAL OIL R&O-46 #10

WEIGHT

ABOVE 80°F: REGAL OIL R&O-46 #20

WEIGHT

SHELL

32° TO 150°: TELLUS OIL 68

-20° TO 32°: TELLUS OIL 23

150° TO 200°: TURBO OIL 150

ROYAL PURPLE

SYNFILM 150 VG 68 SYNTHETIC

LUBE

3410 IOM 1/2010

37

5

Fig. 33