Goulds Pumps 3410 - IOM User Manual

Page 18

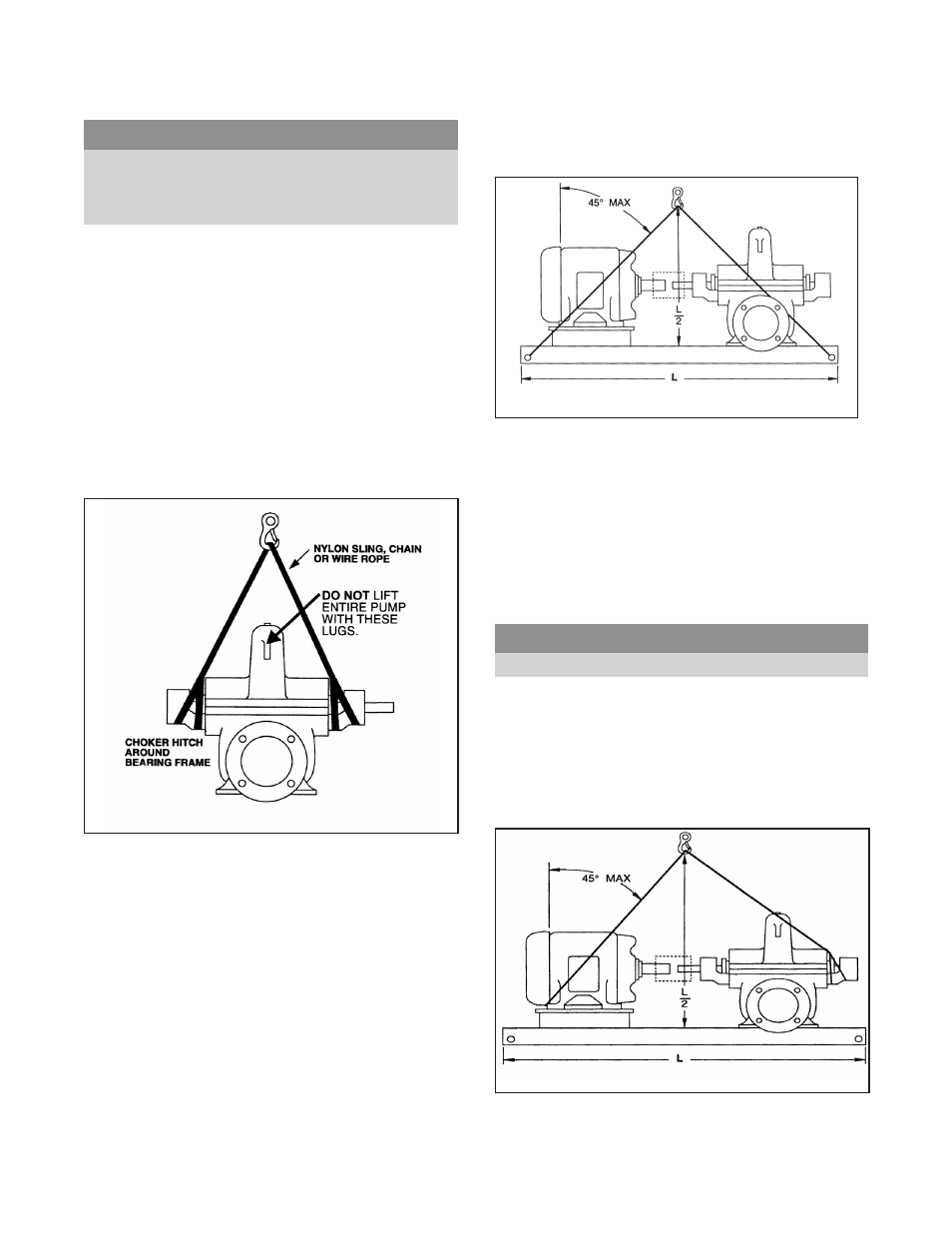

LIFTING THE PUMP

s

!

WARNING

Pump and components are heavy. Failure to properly

lift and support the equipment could result in serious

physical injury, or damage to the pump(s). Steel-toed

shoes must be worn at all times.

The following instructions are for the safe lifting of your

pump.

The unit should be unloaded and handled by lifting equally

at four or more points on the baseplate. The lugs on the

upper half casing are designed for lifting the upper half

casing only.

HORIZONTAL

Bare Pump

1.

Using a nylon sling, chain, or wire rope, hitch around

both bearing housings. (See Fig. 4)

Pump, Base, and Driver

2.

Care must be taken to size equipment for unbalanced

loads which may exist if the driver is not mounted on

the base at the time of lifting. Driver may or may not

be mounted at the factory.

3.

Pump, base, and driver assemblies where the base

length exceeds 100 inches may not be safe to lift as a

complete assembly. Damage to the baseplate may

occur. If the driver has been mounted on the baseplate

at the factory, it is safe to lift the entire assembly. If

driver has not been mounted at the factory and the

overall baseplate length exceeds 100 inches, do not lift

entire assembly consisting of pump, base, and driver.

Instead, lift the pump and baseplate to its final

location without the driver. Then mount the driver.

Bases supplied with lifting holes

Large bases are supplied with lifting holes in the sides or

the ends of the base. (See Fig. 5)

Using ANSI/OSHA Standard “S” hooks, place the “S” hooks in

the holes provided in the four corners of the base. Be sure the

points of the hooks do not touch the bottom of the pump base.

Attach nylon slings, chains, or wire rope to the “S” hooks. Size

the equipment for the load so the lift angle will be less than 45°

from the vertical.

Bases supplied without lifting holes

Place one sling around the outboard bearing housing.

s

!

WARNING

Do not use lugs on top half of casing.

Place the remaining sling around the back end of the driver as

close to the mounting feet as possible. Make certain sling will not

damage housing cover or conduit boxes.

Join the free ends of the slings together and place over the lifting

hook. Use extreme care when positioning sling under the driver

and bearing housing so it cannot slip off (See Fig. 6).

16

3410 IOM 1/2010

Fig. 4

Fig. 5

Fig. 6