Field operation, Field operation and transporting -2 – 3-3 – Summers 2510 DT User Manual

Page 58

SECTION 3 - OPERATION & MAINTENANCE

3-2

FIELD OPERATION

The following procedure should be used for field operation

of your Summers Diamond Disk & 2510 DT.

1. Remove wing safety lock pins and transport locks and

place in their storage positions.

2. Lower wings for field operation.

3. Level disk. The disk should be adjusted in a level area

of the field.

IMPORTANT!

All pressure must be removed from cylinders before adjusting

eyebolts. Rest Disk on top of the ground, shut tractor off and

relieve pressure by cycling remote lever.

A. First, level the center section (front to rear) by adjusting

the threaded eye bolts located above each hydraulic

cylinder.

B. Second, level the wings with the center section again

by adjusting the threaded eye bolt above each hy-

draulic cylinder.

C. With the front center cylinder in the rear hole, after the

disk has been leveled in working position, it is normal

for the front gangs to be 3-4” lower than the rear gangs

in the fully raised position. This is due to the fact that

when the disk is in working position, the front center tires

run on top of a ridge of soil thrown in by the front gangs.

18-1/2’ and 21-1/2’ Machines

To set depth, install stroke control collars on the front center cylinder

(5” dia. x 10” stroke).

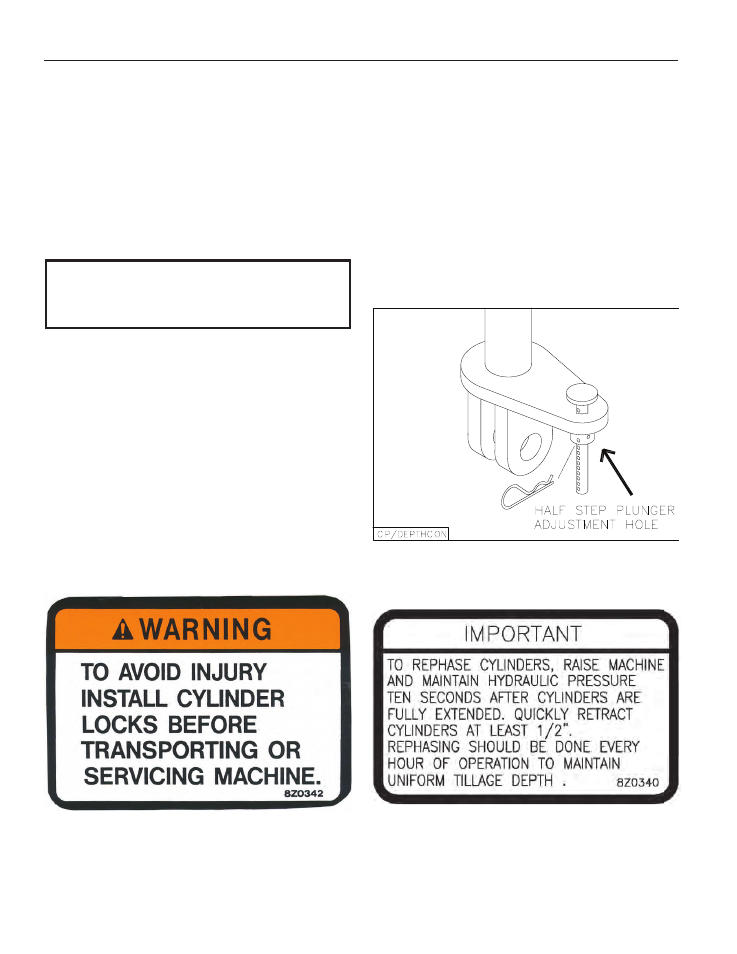

24-1/2’ - 47’ Machines

After determining desired tillage depth, set depth control

plunger accordingly. Standard plunger hole spacing gives

5/16” cylinder stroke adjustment. By rotating plunger 90

degrees, a half step adjustment can be achieved. See

drawing below.