13 cutting blades, 14 transporting, 15 loading and unloading – Wright Serial # 55138 and higher User Manual

Page 30: 16 lubrication

30

WARNING

WARNING

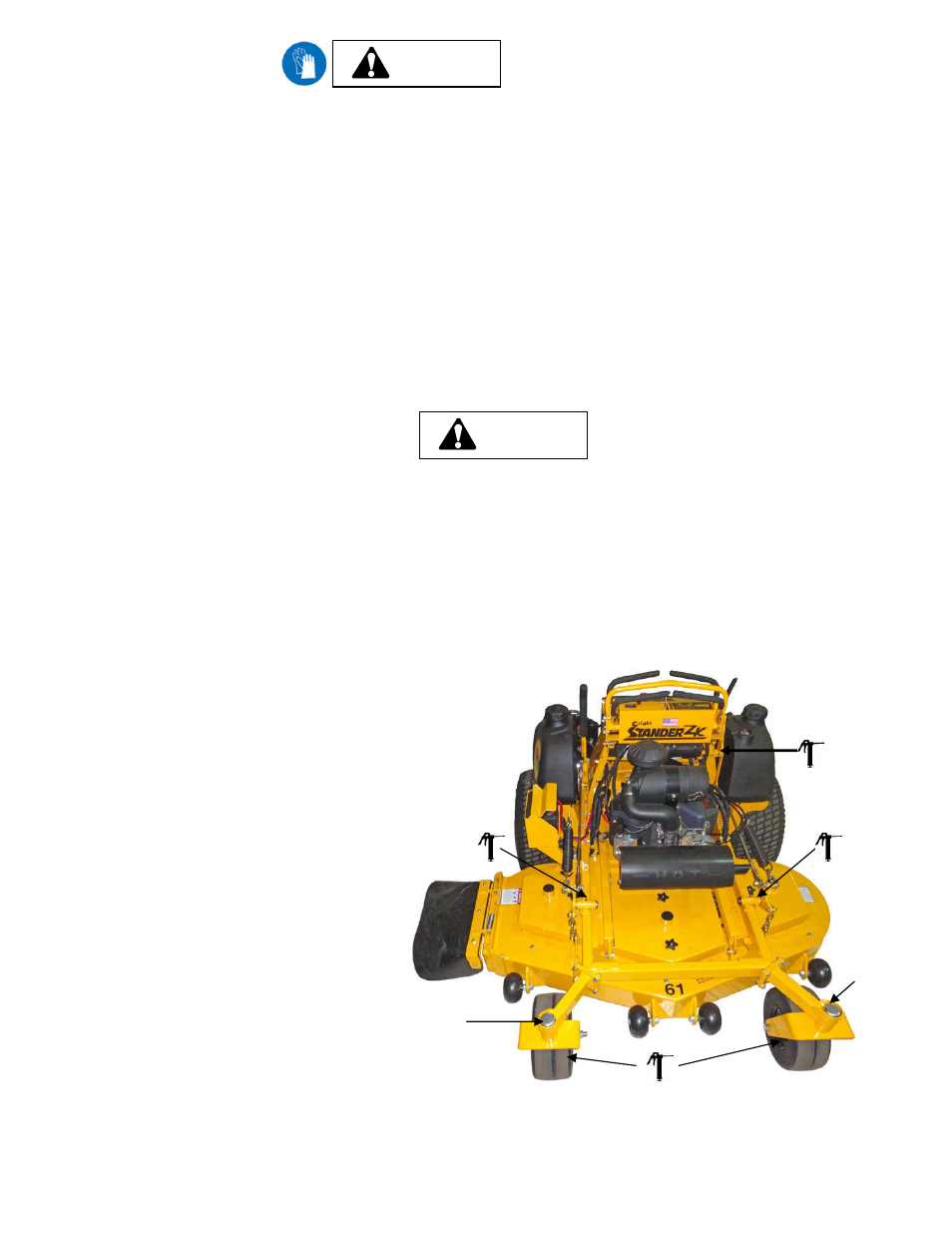

Caster Pivots - Remove

dust cap, cotter pin and

hex nut. Inspect grease

seal and bearings. Fill

chamber with grease and

reinstall in reverse order.

Check

monthly

6.13 Cutting Blades

In order to maintain the best cut, it is important that the blades are well sharpened and not damaged. Bent or

cracked blades or blades with large nicks need to be replaced. Blades must be balanced after sharpening.

To change the blades:

•

Stop engine, remove the key and wait for all moving parts to stop.

•

Engage the parking brake

•

Lift front of mower and secure in the raised position with jack stands.

•

Remove the blade bolt by turning counterclockwise.

•

Apply anti-seize to the blade bolt.

•

Install new or re-sharpened blade, start mounting bolt by hand. (Ensure the blade spacers are

reinstalled with the same qty and location)

•

Torque blade bolt to 70-80 ft/lbs / 95-108 Nm

6.14 Transporting

Use a heavy duty trailer or truck to transport the Stander ZK. Lock brake and block wheels. Securely fasten

the unit to the trailer or truck with straps, chains, cable or ropes.

6.15 Loading and Unloading

Use extreme caution when loading and unloading units on/off trailers or trucks. One full width ramp that

extends beyond the rear tires is recommended rather than individual ramps for each side of the unit. The

ramp should be long enough so that the angles between the ramp and the trailer or truck does not exceed 15

degrees. A steeper angle may cause the mower deck components to get caught as the unit moves from

ramp to trailer or truck. Always put the deck in the transport (up & locked) position when loading or

unloading. Never attempt to turn the mower around on the ramp. Avoid sudden acceleration when driving

up a ramp and sudden deceleration when backing down a ramp.

6.16 Lubrication

Grease with No. 2 general purpose lithium base or molybdenum base grease.

•

Set parking brake, stop the engine

and remove the key.

•

Clean grease fittings with a rag.

•

Connect grease gun to fitting and

pump until grease begins to ooze

out from the bearings.

•

Wipe off excess grease.

•

Do not use spray lube of any kind

on choke and/or throttle cables.

•

Service intervals:

First 8 hours

Every 25 hours

Also see Maintenance chart