5 how to move the mower if the engine won’t start, 6 hydraulic system, 7 oil cooler screen removal and cleaning – Wright Serial # 55138 and higher User Manual

Page 27

27

WARNING

WARNING

6.5 How to Move the Mower if the Engine Won’t Start

Rotate both of the manual “release” valve levers on the rear of each

hydraulic pump about ½ turn counterclockwise. It is important not to

over tighten these levers. Damage may occur to the pump if this valve

is over tightened.

6.6 Hydraulic System

Whenever servicing the hydraulic system, it is of the utmost importance to keep any dirt or debris from

getting into the system. Clean off all parts before disassembly and assembly. When any of the hydraulic

parts are disconnected or removed or when the oil is changed, air must be bled from the system. If air is

entrained in the system, loss of power, excessive heat, and damage to the hydraulic pumps may occur.

First, make sure the oil level in the reservoir is correct. Use fully synthetic oil: Mobil1 15W-50. Lift the

mower so that the rear wheels are off the ground. Be careful to support the mower so that it will not fall or

tip while the system is bled of air. With the bypass valves open and the engine running, slowly move the

control levers back and forth five or six times. Now close the bypass valves and with the engine running,

slowly move the control levers back and forth five or six times. It may be necessary to repeat the above

steps until all the air is purged and the rear wheels are turning at normal speed. After purging is complete,

adjust the oil level in the reservoir if necessary.

•

Low Pressure Hose

•

High Pressure Hose

•

Arrow indicates direction of flow

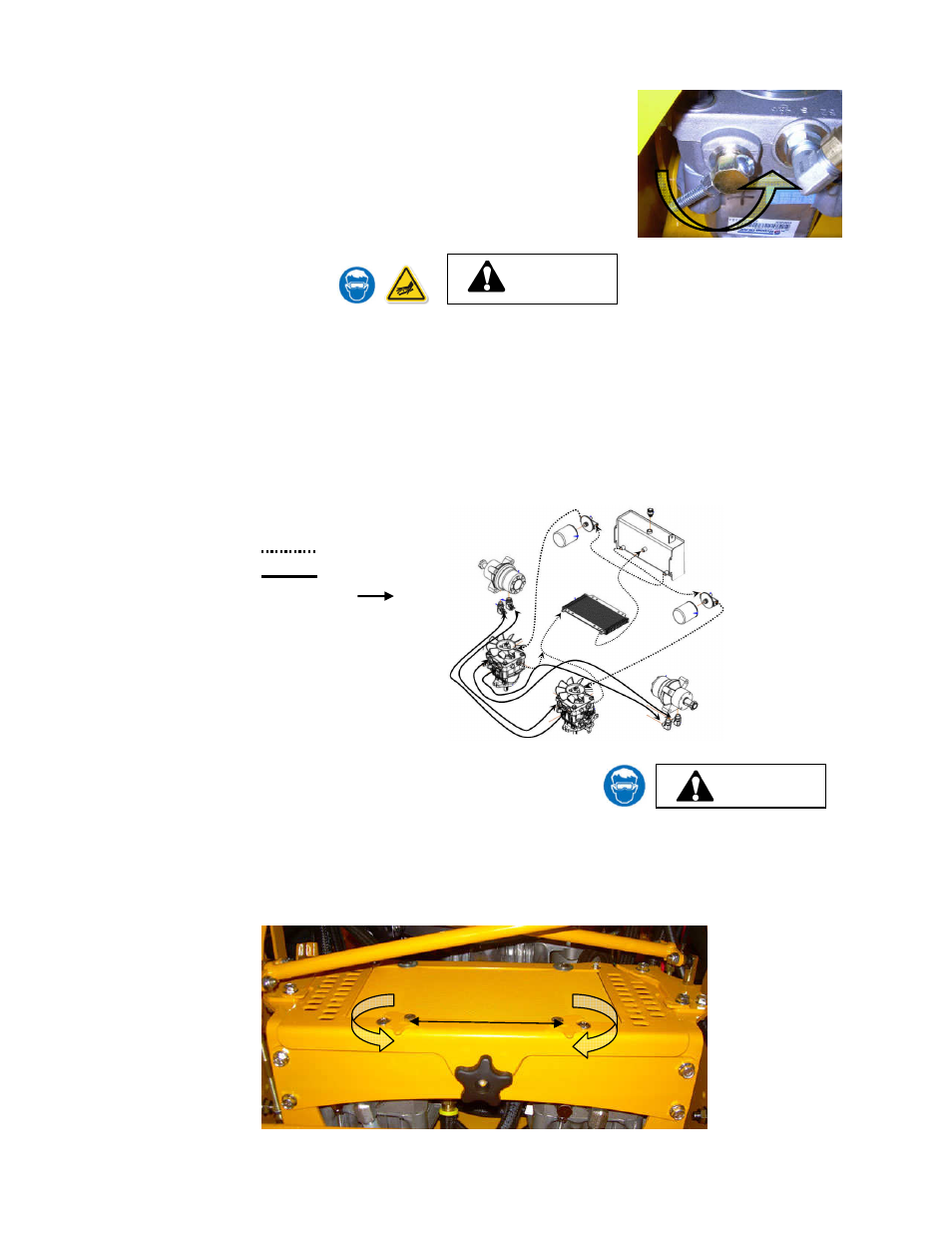

6.7 Oil Cooler Screen Removal and Cleaning

Your Stander ZK is equipped with an oil cooler, the oil cooler debris screen will need to be cleaned several

times a day. Clean more often in bush hog conditions. To clean, “STOP ENGINE” lift thigh pad for access,

either wipe screen or remove screen for cleaning. To remove screen, lift and rotate spring locks to free the

screen. The screen is bowed to prevent a rattle and should be installed hump down, like a “U”. Using

compressed air or water to clean may or may not be necessary.