Pumptec 356U SERIES User Manual

Page 8

8

Version 061113

Pumptec Operating Instructions and Parts Manual

PUMP SERIES 348U | 350U | 356U

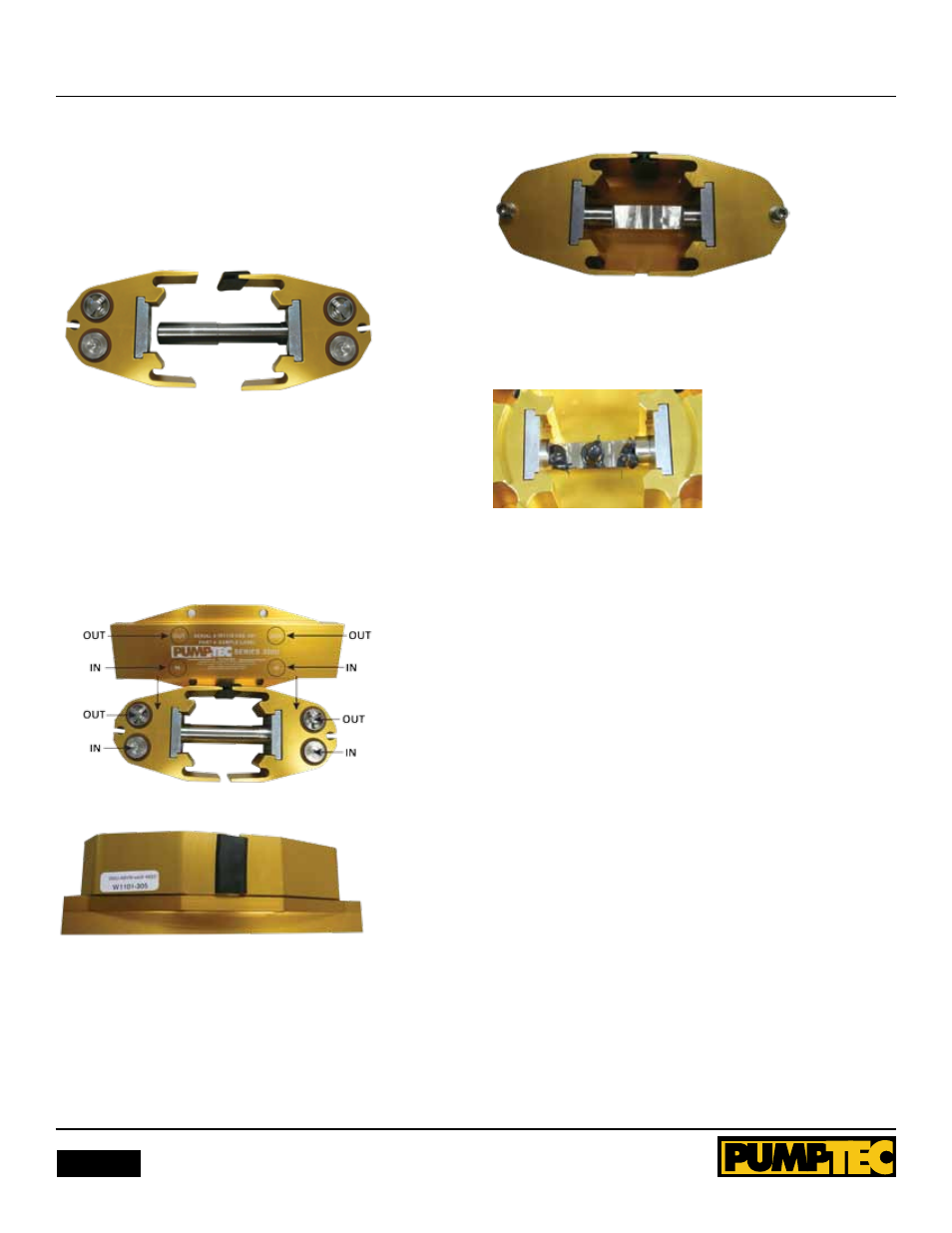

9. Adjust plunger slot position towards center and have slot

facing work surface. Replace all valves, O-rings and white wash-

ers. Refer to image and manifold label to understand proper

orientation.

Figure 6

10. Place manifold on top of plunger and head assembly. It may

be necessary to move heads on plunger to have valves align

with valve pockets on manifold. be careful to not lose the white

washers in the manifold during reassembly.

IMPortANt:

It is imparative the alignment of OUT/In

ports coincide with valves as indicated in Figure 7.

PROPER AlIgnMEnT

Figure 7

11. Turn assembly over and place shorter bolt and washer

assembly into heads and tighten finger tight. DO nOT tighten

completely at this time.

Figure 8

12. Install black grease from included packet into corners and

center of plunger slot as shown.

Figure 9

13. Mount pump back onto motor and tighten mounting bolts

to 14 in/lbs. of torque. Tighten head bolts to 14 in/lbs. of

torque.

LUBriCAtiON

Apply 1.5 oz of suppliers black grease to the corners and center

of plunger slot at the time of service.

StorINg

For extended storing, or between use in cold climates, drain all

pumped liquids from pump and flush with antifreeze solution

to prevent freezing and damage to the pump. DO nOT RUn

PUMP WITH FROZEn lIQUID.

Note:

Each system’s maintenance cycle will be unique. If

system performance decreases, check immediately. If no wear

at 500 hours, check again at 1000 hours and each 500 hours

until wear is observed. Valves typically require changing every

seal change. Duty cycle, temperature, quality of pumped liquid

and inlet feed conditions all effect the life of a pump’s wear

parts and service cycle.

Note:

Remember to service the regulator/uploader at each

seal servicing and check all system accessories and connections

before resuming operation.