Installation, Pad mounting – LiftMaster SL575 Heavy-Duty Commercial Slide Gate Operator User Manual

Page 10

10

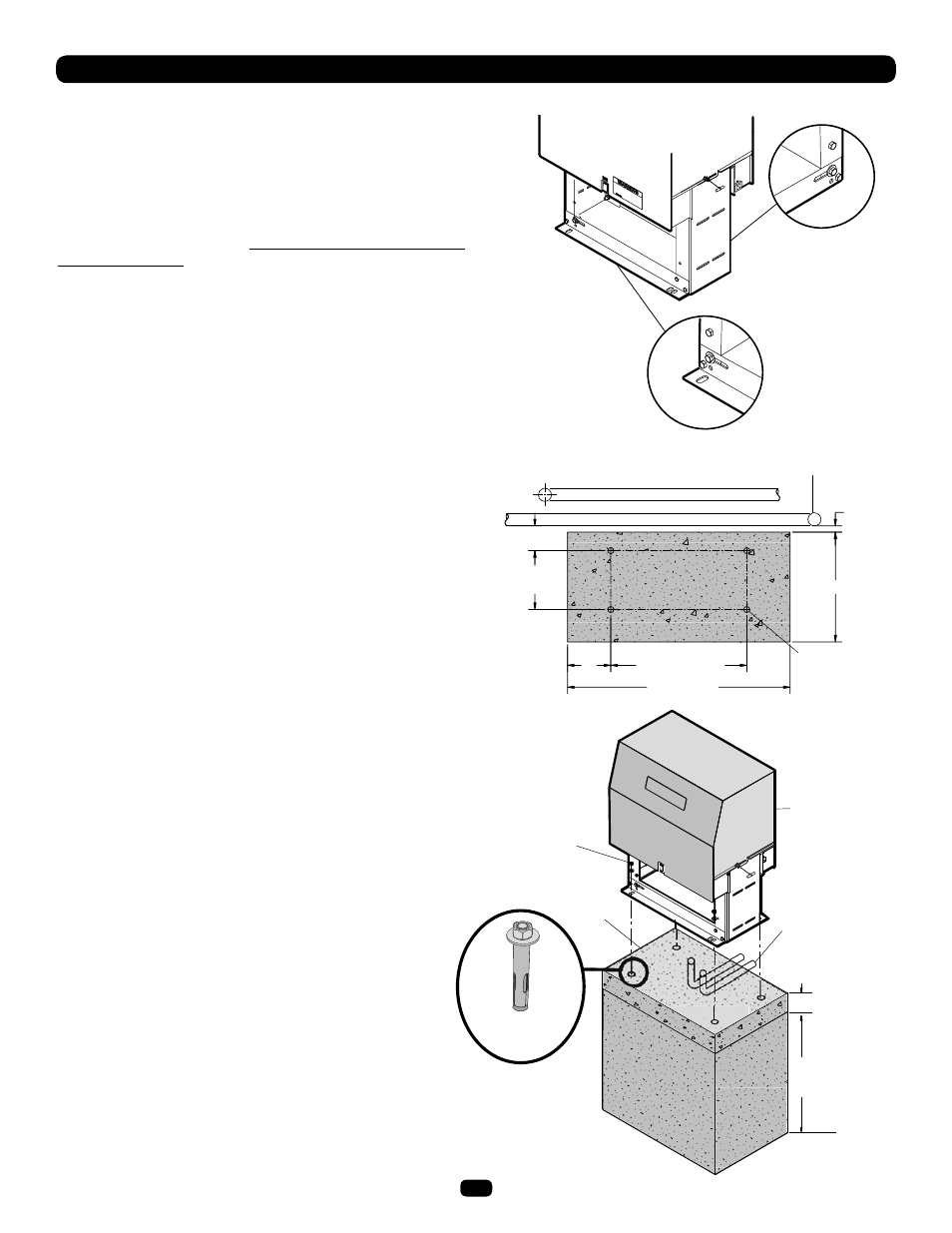

PAD MOUNTING

RETRO-FIT INSTALLATION

The operator is shipped from the factory with the lower mounting

angles configured out (Figure 1). If you have pad constrictions,

either angle can be unbolted and reversed to ‘angle in’.

NOTE: If you are replacing an SL540/SL570 and wish to use the

same pad mounting hardware, the gate side mounting angle must

be installed angle in.

NEW INSTALLATION

Concrete Pad Preparation:

1. Lay out concrete pad. (Figure 2).

2. Locate electrical conduit, as required, prior to pouring

concrete.

3. Pour concrete pad.

4. Secure operator (Figure 3) to the concrete pad using four 1/2"

concrete anchors (not provided).

Figure 1

Figure 2

Figure 3

Angle In

Angle Out

Fence In

Rear of Gate or

Back Frame

1" (2.5 cm)

18" (45.7 cm)

Concrete

Anchor Holes

21-1/8" (53.7 cm)

36" (91.4 cm)

10-7/8"

(27.6 cm)

4" (10.2 cm)

Drive and Idler

Sprocket Toward

Gate Side

Power and Control Wiring

Should Be Run In

Separate Conduit

2" to 4"

(5.1 to 10.2 cm)

Above Grade

Depth Required By

Local Codes or Below

Frost Line

1/2" Concrete

Anchors

(4 Required)

Concrete Pad

Using Suitable Hardware To

Secure Operator To Concrete

Anchors

7"

(17.8 cm)

I N S T A L L A T I O N