Set up instructions, Step 1, Step 2 – IPA Tools 9040PN Fuel Tank Sweeper with Pneumatic Pump User Manual

Page 5: Tank sweeping set-up

5

SET UP INSTRUCTIONS:

STEP 1

It is recommended that you visit the site 48 hours before tank sweeping to prepare the

tank and assess the site condition. Using the optional IPA9041 sampling tool, insert the

sampler all the way down to the bottom of the tank to be cleaned. Draw the piston shaft

up enough to get a good sample of the fuel (aprox.12”). Remove the sampler and note

the amount of water and crude at the bottom of the

tank. It is recommend that you transfer the sample

into a glass jar and allow the various

contaminants to settle and separate for

24 hours. This will give you an idea of the fuel

condition inside the tank and the amount and type

of the contaminated fuel.

STEP 2

Add an algae bio-cleaner or equivalent to the tank in appropriate amounts. Using the

sampler, stir the tank briskly to mix the algae cleaner into the oil. After 48 hours, the

algae should be killed off and the tank is now ready for sweeping. If convenient and

safe, you may use a small jack to elevate the tank a few degrees on one side to allow

the majority of contaminates to collect on one end of the tank. This is the end you will

choose to sweep.

TANK SWEEPING SET-UP:

1. Set up your Tank Sweeper™ near the tank to be cleaned allowing enough room

for

the inlet hose to reach the tank.

2. Install the outlet hose to a 55 gallon drum similar making sure that the vent cap is

loose. (Note: Use a clean, and leak free 55 gallon drum).

3. Connect the suction stick to the inlet hose via couplings being sure to use the

locking pins so the locking levers do to vibrate loose.

4. Insert the suction stick adapter all the way down to the bottom of the oil tank to be cleaned.

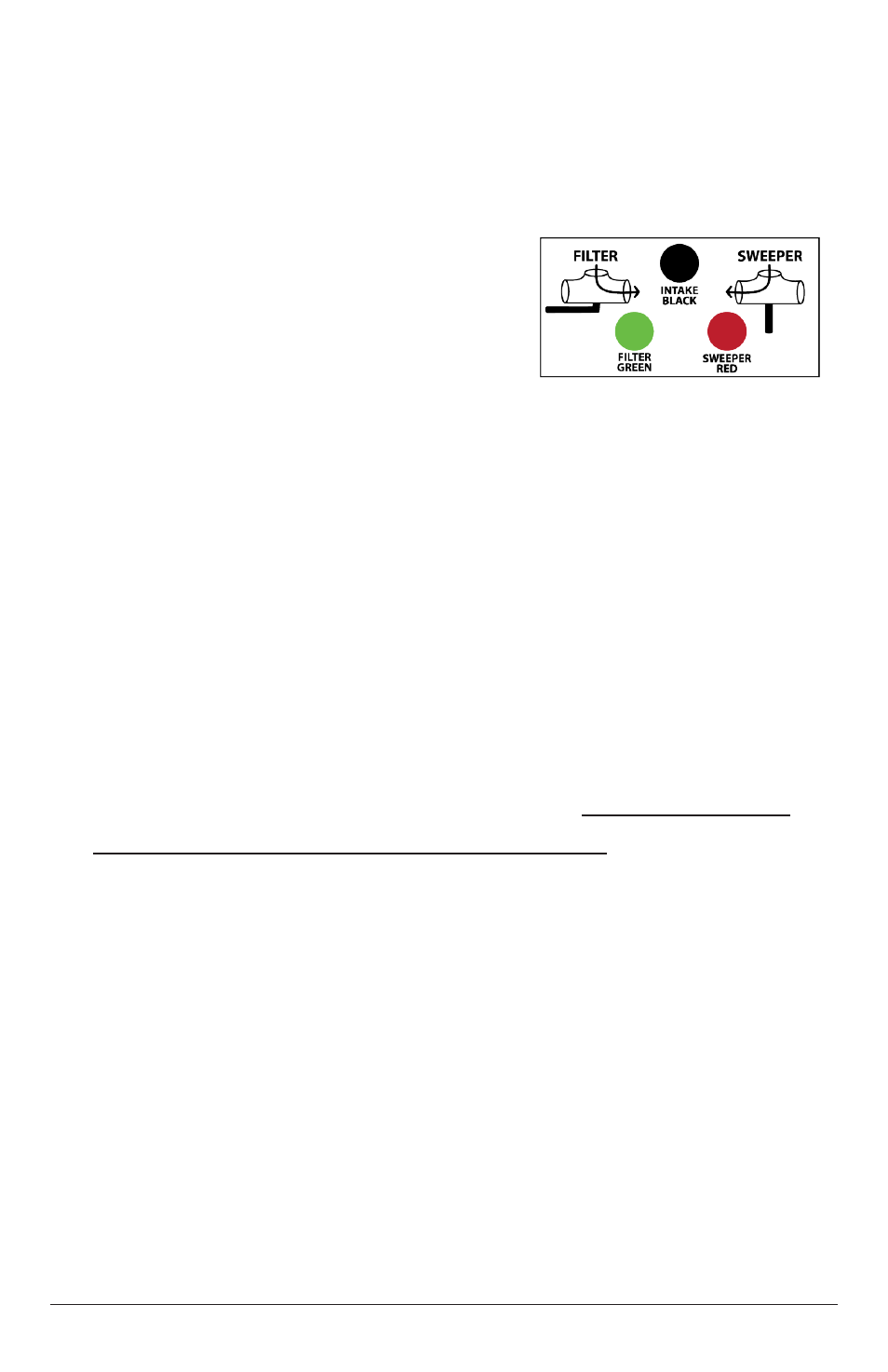

5. Be certain to turn the main ball valve to Sweeper™ direction.

6. Attach air supply line to the inlet air on the pump assembly. Do not turn on the air

ball valve yet.

7. Set the air pressure to 50 PSI. Air Operating Range is from 50 PSI to 100 PSI. A

setting of 50 PSI is recommended to give the operator more control of the sweeping

operation. Do not turn on the air ball valve yet.

NOTE: When ready to sweep the tank, be sure to check all connections for leaks

and be prepared to shut down the sweeper in the event of a leak. Have your Emer-

gency Spill Kit available and in reach. It is best to have this operation performed

by two people--one operating the air supply and the other person doing the actual

sweeping of the tank.